A kind of coal combustion additive and its application method

A coal-fired additive and additive technology, which is applied in the field of coal-fired additives, can solve problems such as poor treatment effect, high cost, and complicated control process, and achieve the effects of less corrosion, less environmental pollution, and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

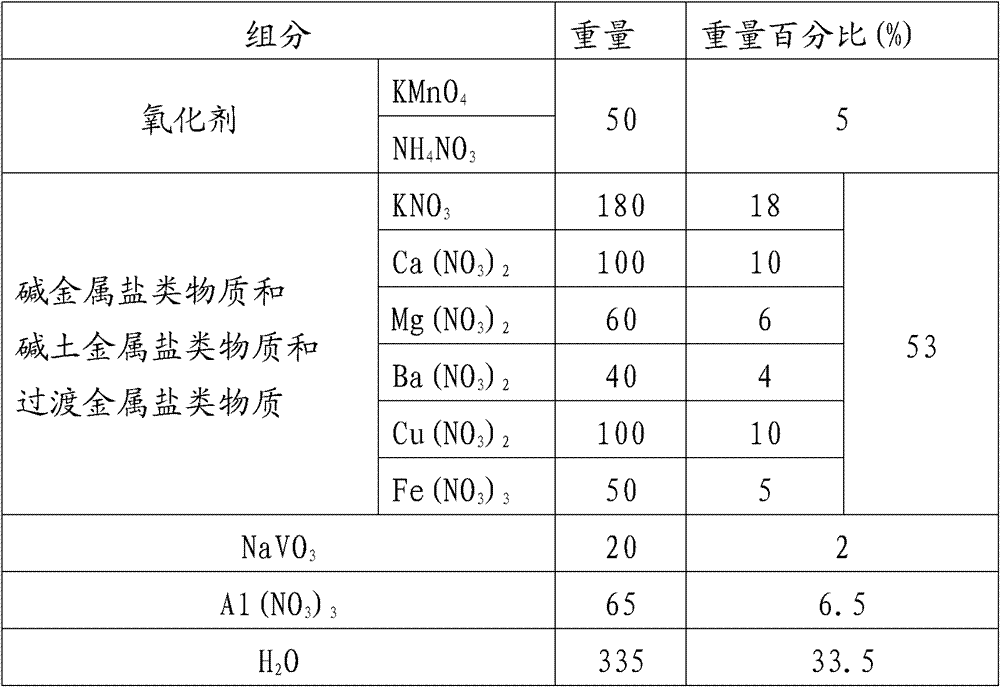

[0036] Composition and weight percent of coal-fired additive are (total weight is 1000g):

[0037]

[0038] The steps of using the coal-fired additive are as follows:

[0039] a. Mix the above-mentioned coal-fired additives in proportion, stir, and heat to 50°C;

[0040] b. The cooled coal-fired additive mixture is injected into the furnace by compressed air, and the pressure of the compressed air is 0.5MPa.

[0041] The amount of coal-burning additive injected per second is adjusted according to the total usage. The coal-burning additive solution is heated so that the composition is completely dissolved, and the compounds of the additive used do not decompose in this case.

[0042]Coal-fired additives are injected into the furnace by compressed air. The additives have good dispersion, which makes the additives and coal powder mix more uniformly, increases the contact area between additives and coal powders, and makes the additives more effective.

[0043] After testing,...

Embodiment 2

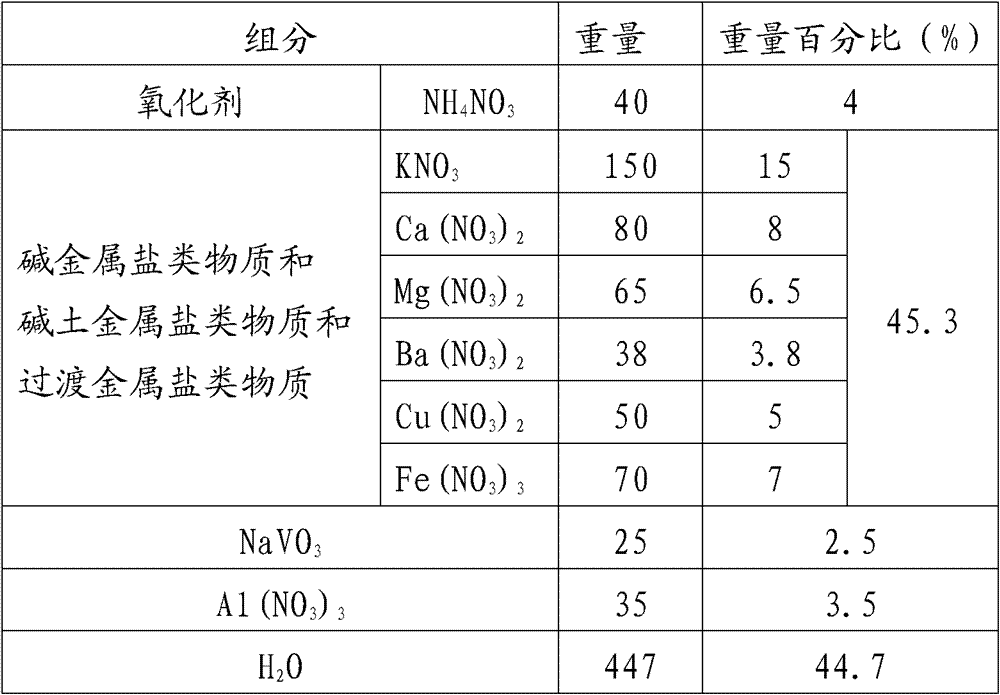

[0045] Composition and weight percent of coal-fired additive are (total weight is 1000g):

[0046]

[0047] The steps of using the coal-fired additive are as follows:

[0048] a. Mix the above-mentioned coal-fired additives in proportion, stir, and heat to 40°C;

[0049] b. The cooled coal-fired additive mixture is injected into the furnace by compressed air, and the pressure of the compressed air is 0.6MPa.

[0050] Preferably, the injection mode of the coal-burning additive is intermittent, each interval time is 5-10 minutes, and each injection time is 20-30s. Due to the small amount of coal-fired additives, the intermittent injection method can better control the addition process of additives, thereby saving the amount of additives and compressed air used, and at the same time, ensuring the uniform mixing of additives and coal powder.

[0051] Preferably, the injection point of the coal-burning additive is set at the fire sight hole of the coal-burning equipment. In t...

Embodiment 3

[0054] Composition and weight percent of coal-fired additive are (total weight is 1000g):

[0055]

[0056] The steps of using the coal-fired additive are as follows:

[0057] a. Mix the above-mentioned coal-fired additives in proportion, stir, and heat to 60°C;

[0058] b. The cooled coal-fired additive mixture is injected into the furnace by compressed air, and the pressure of the compressed air is 0.7MPa.

[0059] Preferably, the injection mode of the coal-burning additive is intermittent, each intermittent time is 2-5 minutes, and each injection time is 10-20s.

[0060] Preferably, the injection point of the coal-fired additive is set at the fire sight hole of the coal-burning equipment, which has high safety performance.

[0061] After testing, the use of the above-mentioned coal-fired additives has a good combustion-supporting effect and high coal combustion efficiency. When used on coal-fired equipment with an efficiency of 65-80%, it can save about 8% of coal; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com