Method for producing clean gasoline

A gasoline and clean technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of limited reduction of gasoline olefin content, influence of target product selectivity, limitation of device operation flexibility, etc., and achieve long operation cycle. , high selectivity and activity, the effect of low octane loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

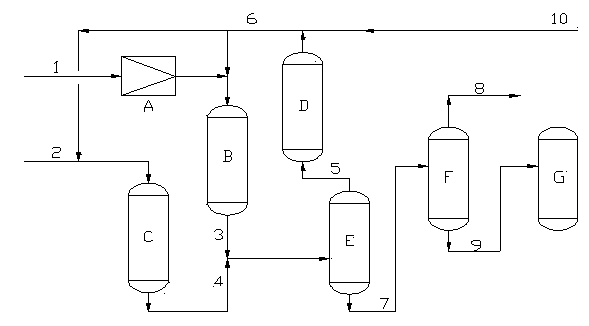

Image

Examples

preparation example Construction

[0040] The preparation method of the hydrodemercaptan catalyst is as follows: the aqueous solution of copper-containing compound, zinc-containing compound and phosphorus-containing compound is heated at 60-100°C to obtain a stable co-impregnation solution, and the above-mentioned co-immersion solution is impregnated once saturated It is obtained by impregnating the carrier, drying at 80-150°C for 2-8 hours, and roasting at 300-600°C for 5-10 hours.

[0041] In the method of the present invention, the preparation of the amorphous alumina, silicon-containing alumina and titanium-containing alumina carrier required for the hydrodesulfurization catalyst and hydrodemercaptan catalyst can be made of amorphous alumina, silicon-containing alumina or Titanium-containing alumina is prepared by adding peptizer, extrusion aid or silica sol, kneading, extruding, drying at 80-150°C for 2-8 hours, and roasting at 500-650°C for 2-5 hours. The amorphous alumina, silicon-containing alumina and ...

example 1

[0053] In this example, an alumina carrier shared by a hydrodesulfurization catalyst and a hydrodemercaptan catalyst is prepared.

[0054] Weigh 1000g pseudo-thin water aluminum hydroxide powder (Al 2 o 3 Dry basis content is 78wt%), adding Al 2 o 3 5wt% squid powder extrusion aid on a dry basis, 200mL of a 10% nitric acid aqueous solution, mixed and rolled to form a plastic powder, and a cylindrical strip with a diameter of 1.5mm was prepared with an extruder, and dried at 120°C 8 hours, calcination at 500° C. for 5 hours to prepare the catalyst carrier T-1.

example 2

[0056] This example prepares a kind of highly active MoO by step-by-step impregnation method 3 (13.0wt%)-CoO(4.0wt%)-P 2 o 5 (1.5wt%)-K 2 O-(2.0wt%) / Al 2 o 3 catalyst.

[0057] Press Catalyst on P 2 o 5 The content is 1.5wt%, K 2 O content is 2.0wt%, take quantitative phosphoric acid, potassium nitrate, add deionized water, make 120mL impregnating solution, then, spray on the catalyst carrier prepared in Example 1 of 160g. P 2 o 5 (1.5wt%)-K 2 O-(2.0wt%) / Al 2 o 3 Catalyst intermediate.

[0058] MoO on Catalyst 3 The content is 13.0wt%, and the CoO content is 4.0wt%. Take quantitative molybdenum oxide and basic cobalt carbonate, add deionized water to make 60mL impregnation solution, and then spray it on 80g of the above-mentioned catalyst intermediate. Highly active MoO was prepared by drying at 120°C for 8 hours and calcining at 490°C for 6 hours 3 (13.0wt%)-CoO(4.0wt%)-P 2 o 5 (1.5wt%)-K 2 O-(2.0wt%) / Al 2 o 3 catalyst. The catalyst is referred to as HAC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com