Device and method for realizing tamping coking on ordinary coke oven

A conventional, coke oven technology, applied in the field of coking, can solve the problem that ordinary coke ovens cannot smelt rammed coke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

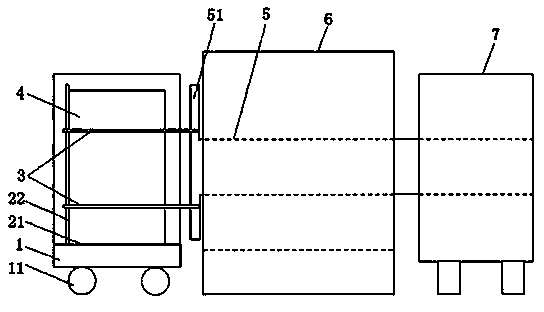

[0024] Such as figure 1 , 2 , 3, the present invention realizes the method for tamping coking on conventional coke oven, comprises the step of tamping coking carried out on conventional coke oven 6, the coke push-out step that carries out by pushing coke car 7 after coking, and by coke quenching car 1 The coke extinguishing step that carries out is characterized in that following steps are passed through before coking:

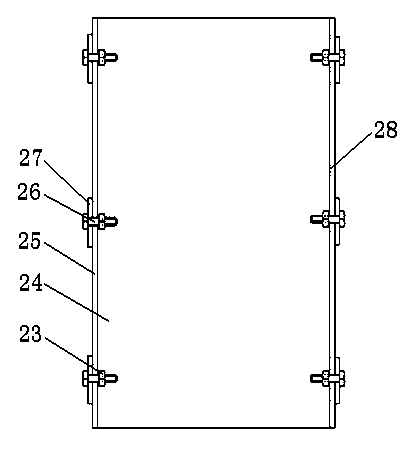

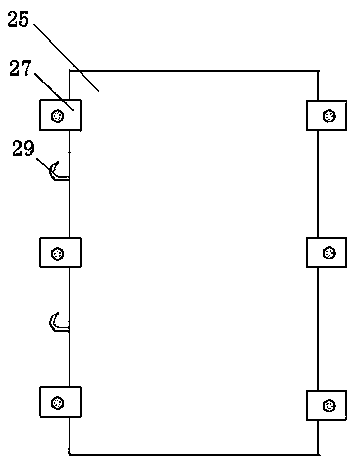

[0025] A. Put the tamping box with an open top formed by the bottom plate 21 and the front, rear, left and right side plates 24, 22, 25, 28 movably connected on the coke quenching car 1, and put the conventional coking coal into the tamping Inside the box, after manual tamping, move to the left side of the coke oven 6;

[0026] B. After disassembling the front, left and right side panels 24, 25 and 28 of the tamping box, fix one end of the left and right symmetrical upper and lower traction parts 3 (steel wires) on the corresponding upper and lower surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com