Steering shaft with misassembly prevention structure

A steering shaft and wrong installation technology, applied to the steering control installed on the car, the steering control installed on the car, the steering column, etc., can solve the problem of wrong installation of the yoke and the rotating shaft, can not be confirmed immediately, fall off and so on , to prevent wrong assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

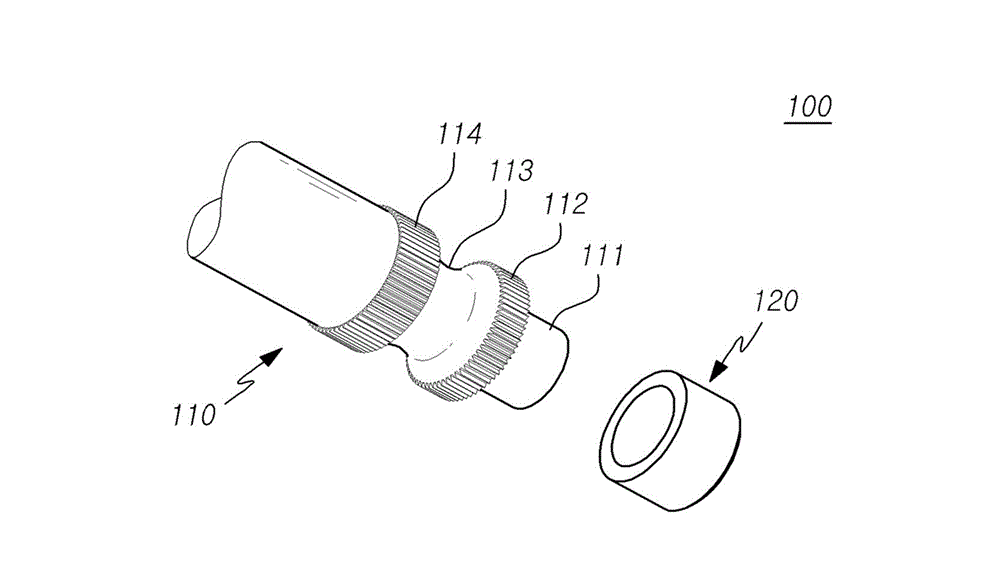

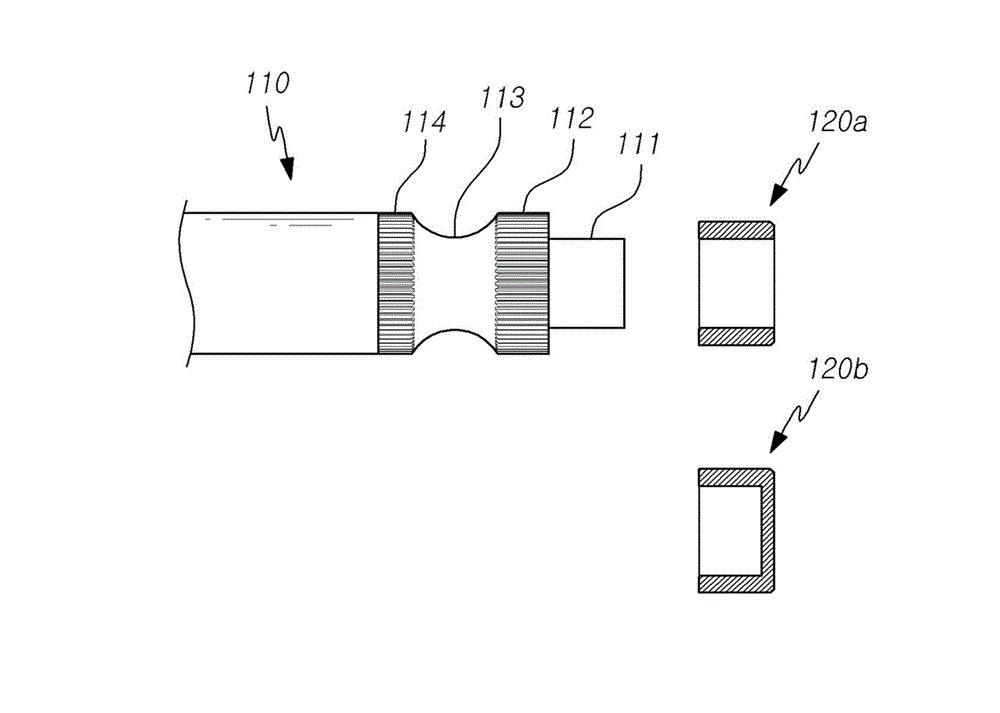

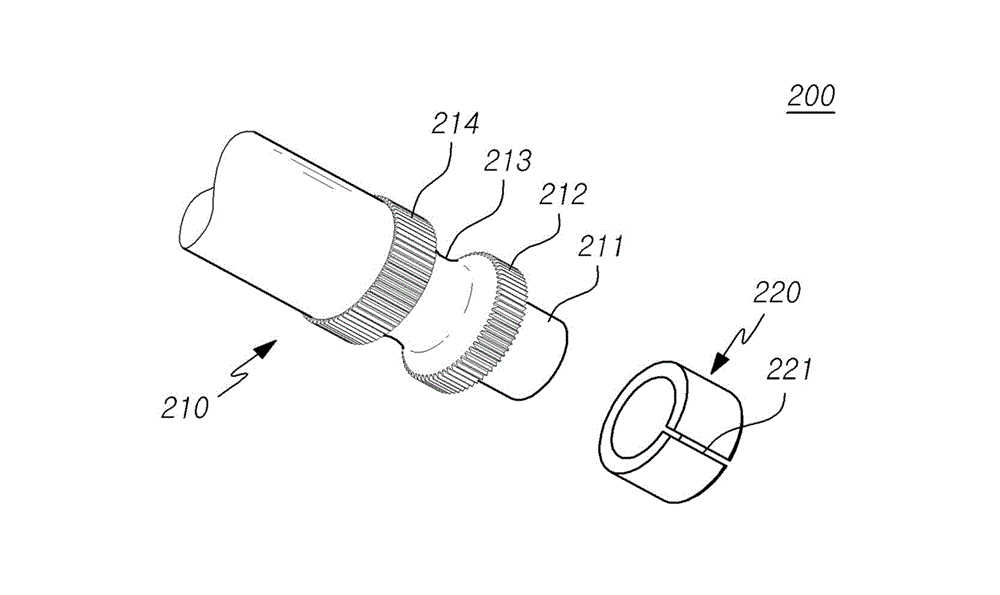

[0034] The steering shaft with a structure for preventing misassembly disclosed herein is made by assembling a rotating shaft, a yoke, etc., when the rotating shaft and the yoke are incorrectly assembled and configured in this way, the rotating shaft and The yoke rotates unharmoniously, but when one of the rotating shaft and the yoke is empty, the wrong installation state can be quickly detected to prevent incorrect installation.

[0035] For this purpose, the steering shaft with a structure for preventing misassembly includes: a rotating shaft, including: a torsion bar formed from one end of the rotating shaft along the axial direction; and serrations formed from the end of the torsion bar And on the outer surface of the rotating shaft; and a groove formed from the end of the serration as a groove; a sliding element inserted into the sliding element through the torsion bar, the sliding element and the A rotating shaft coupling, and a yoke, including: serrations formed on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com