Special device for assembling of inner container and outer container of copious cooling container

A special device, the technology of the outer container, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of not ensuring the uniform gap between the inner and outer containers, and achieve the effect of simple structure, high concentricity, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

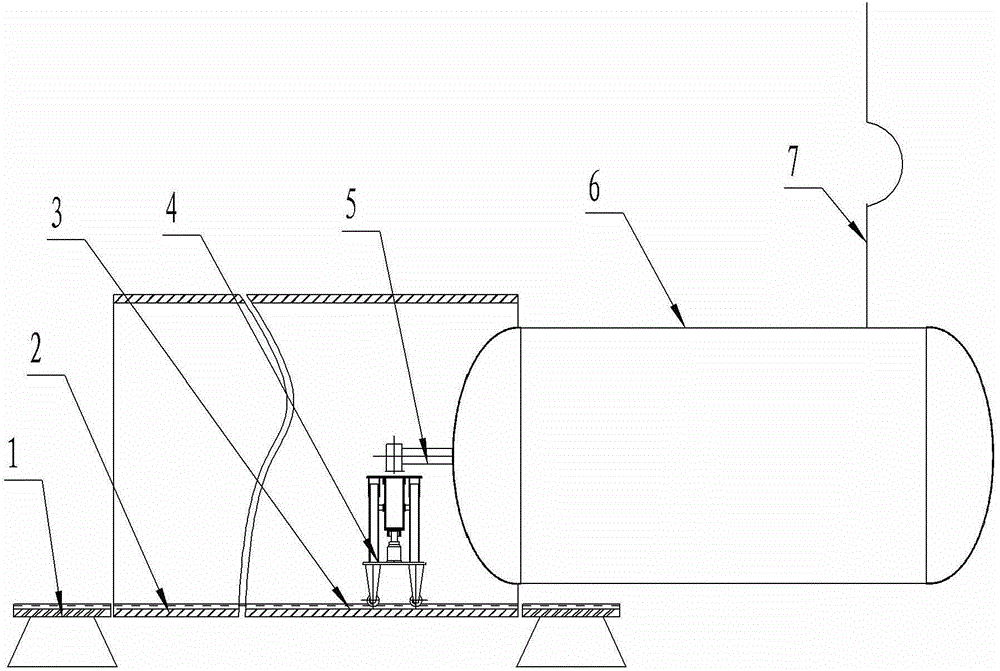

[0014] Embodiment 1, a special device for pairing the inner and outer containers of the cryogenic container, is characterized in that: the guide rail system is composed of the guide rail 3 located at the bottom of the outer cylinder body 2 of the cryogenic container and the external guide rails and brackets 1 at both ends thereof, The tractor 4 that slides on the guide rail is installed on the inner container pull rod 5 at the center of one end of the cryogenic container inner container 6 and is fixed on the other end of the inner container hoisting device 7 to form.

Embodiment 2

[0015] Embodiment 2, a special device for pairing the inner and outer containers of the cryogenic container, is characterized in that: the guide rail system is composed of the guide rail 3 located at the bottom of the outer cylinder body 2 of the cryogenic container and the external guide rails and brackets 1 at both ends thereof, The tractor 4 that slides on the guide rail is installed on the inner container pull rod 5 at the center of one end of the cryogenic container inner container 6 and is fixed on the other end of the inner container hoisting device 7 to form.

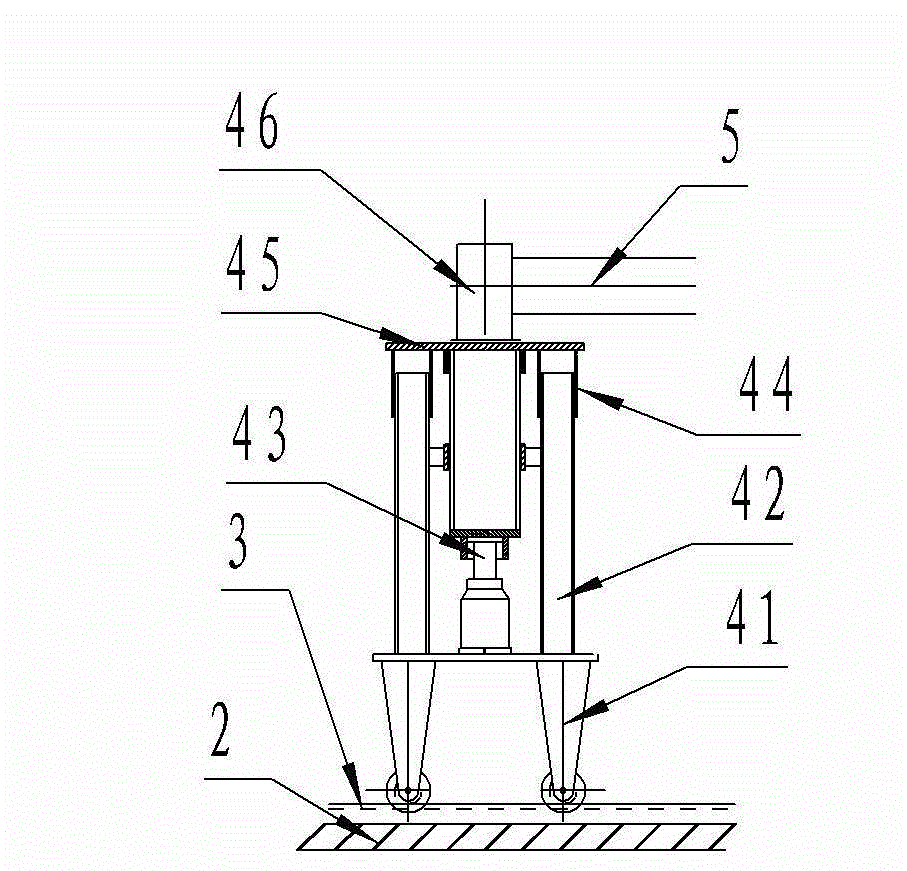

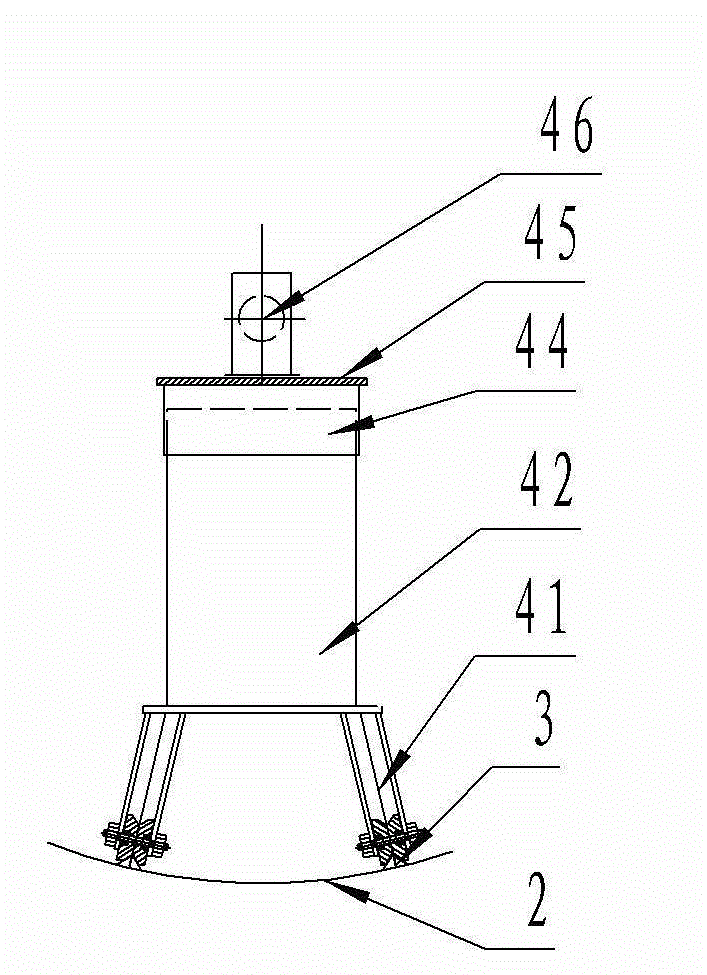

[0016] The lower part of the tractor is a bracket 41 with rollers, the top of the vertical adjustment device 43 installed on the support and the top of the lateral adjustment device are equipped with a tractor platform 45, and the platform is provided with a pull rod holder 46.

[0017] The up and down adjustment device is a hydraulic lifting device with a guide device, and the lateral adjustment device is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com