Marine large-size plane milling device and machining method thereof

A processing device and large-scale technology, applied in the direction of feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing processing efficiency, achieve high processing quality, reduce vibration, and ensure the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

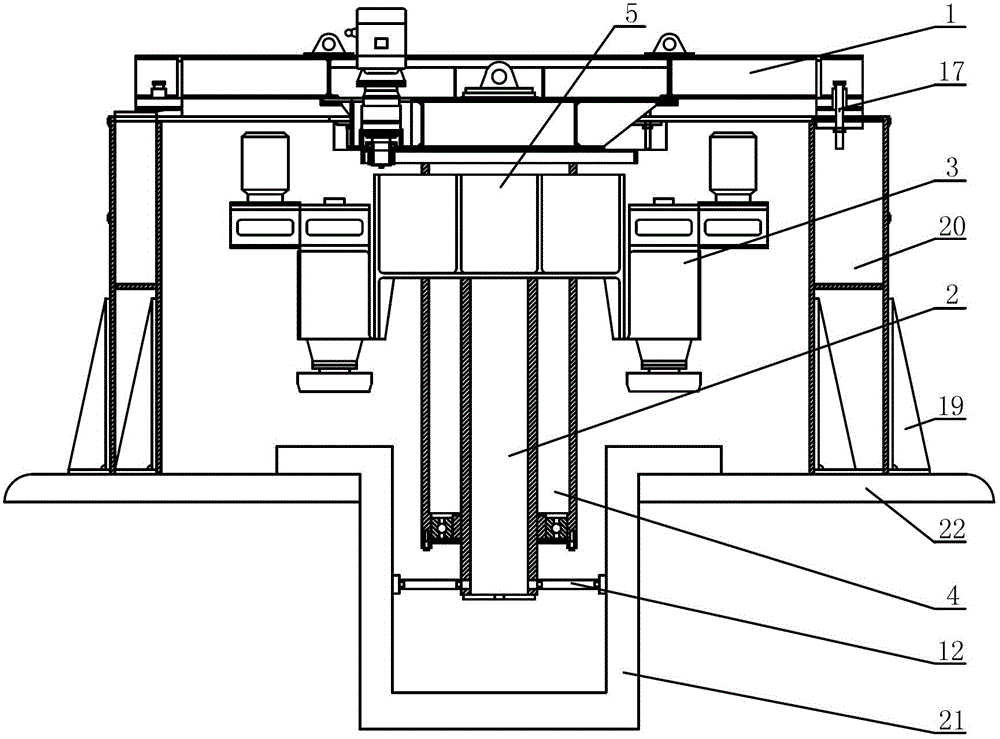

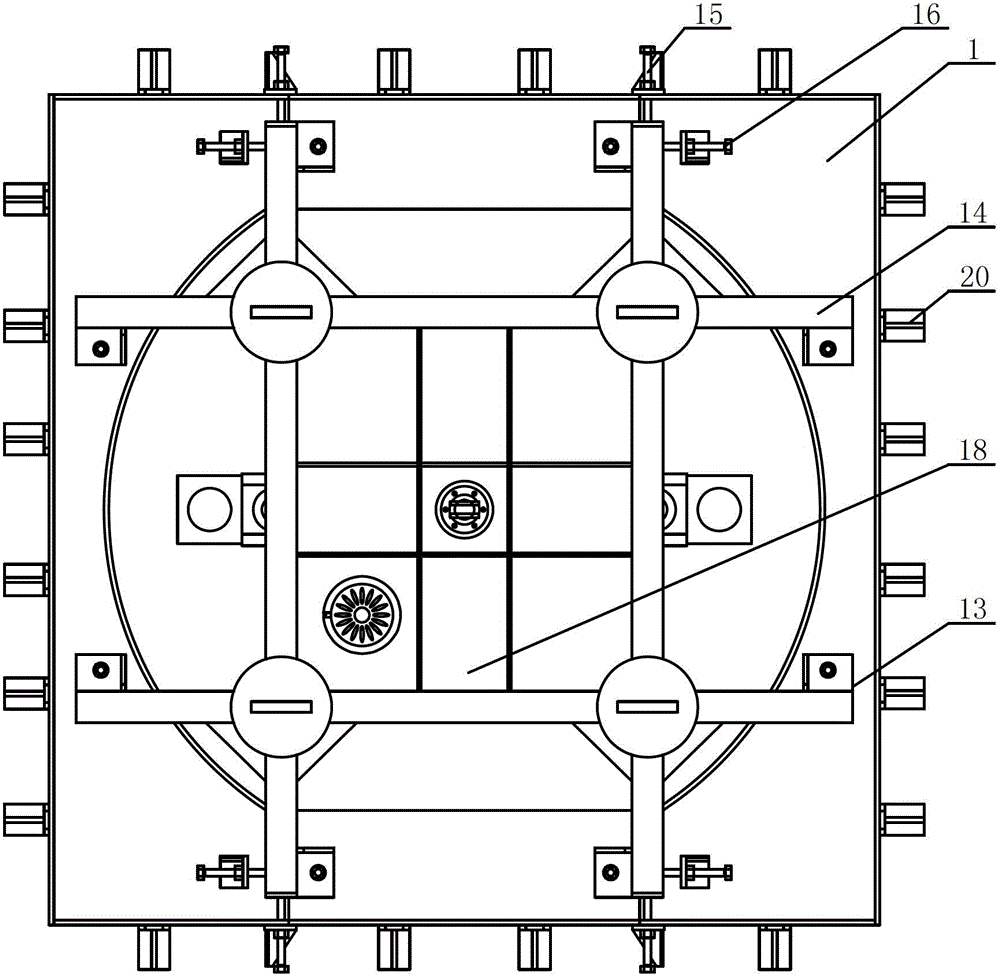

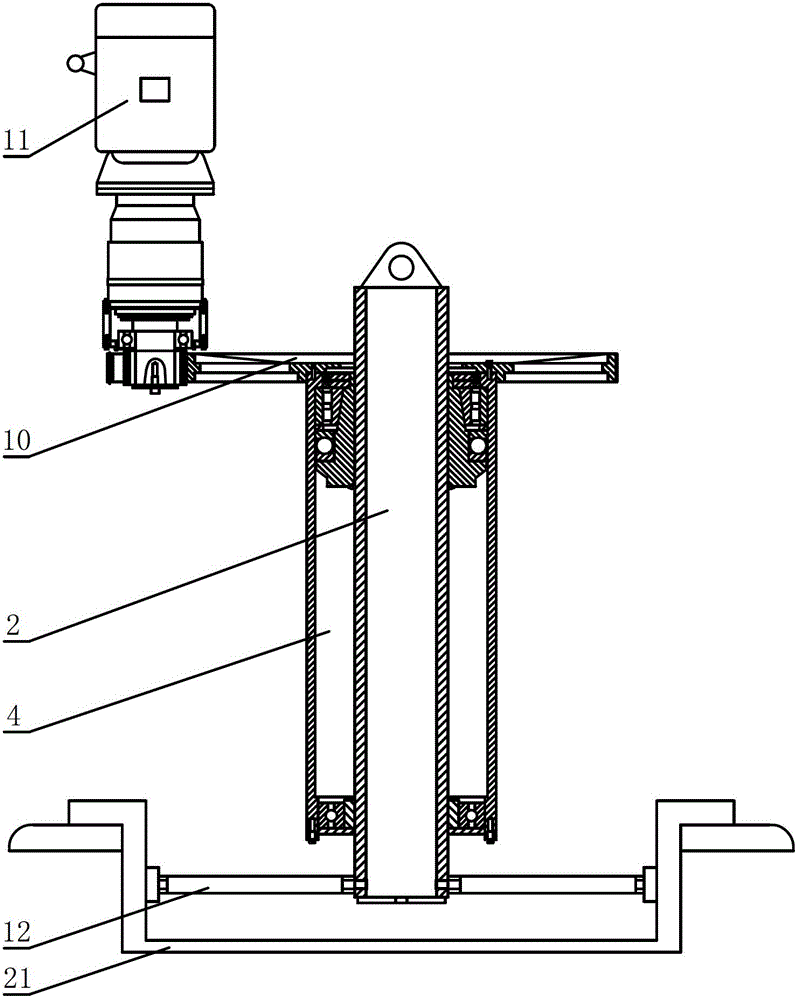

[0029] see figure 1 As shown, the marine large-size plane milling device in the embodiment of the present invention includes a supporting frame 1 , a main shaft 2 , a tool holder 3 and a rotating sleeve 4 . The inside of the support frame 1 has a circular opening matching the ring-shaped workpiece to be processed. The main shaft 2 is set inside the support frame 1 and fixedly connected to the inner top of the support frame 1. The rotating sleeve 4 is set on the outer wall of the main shaft 2. , the rotating sleeve 4 is connected with the main shaft 2 through a bearing, and the rotating sleeve 4 is fixedly connected with the tool holder 3 . The rotating sleeve 4 can rotate around the main shaft 2 when it is stressed, and the tool holder 3 can rotate around the main shaft 2 driven by the rotating sleeve 4 .

[0030] see figure 1 , figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com