Self-walking type peanut combine

A combine harvester, self-propelled technology, related to peanut harvesting technology. , In the field of self-propelled peanut combine harvesters, it can solve the problems of farmers' high labor intensity, low fruit picking rate, and lack of fruit picking, and achieve the effects of stable and reliable operation performance, easy adjustment and operation, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

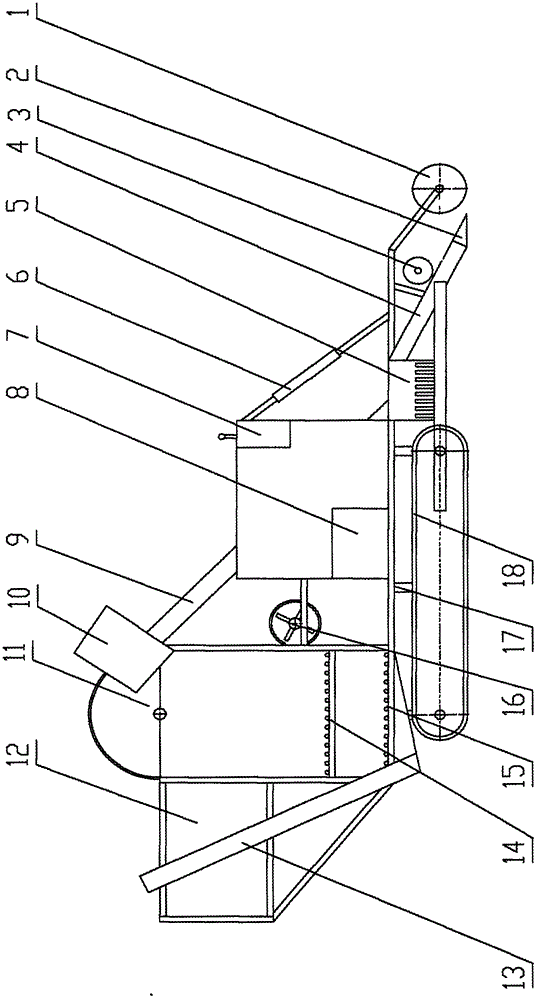

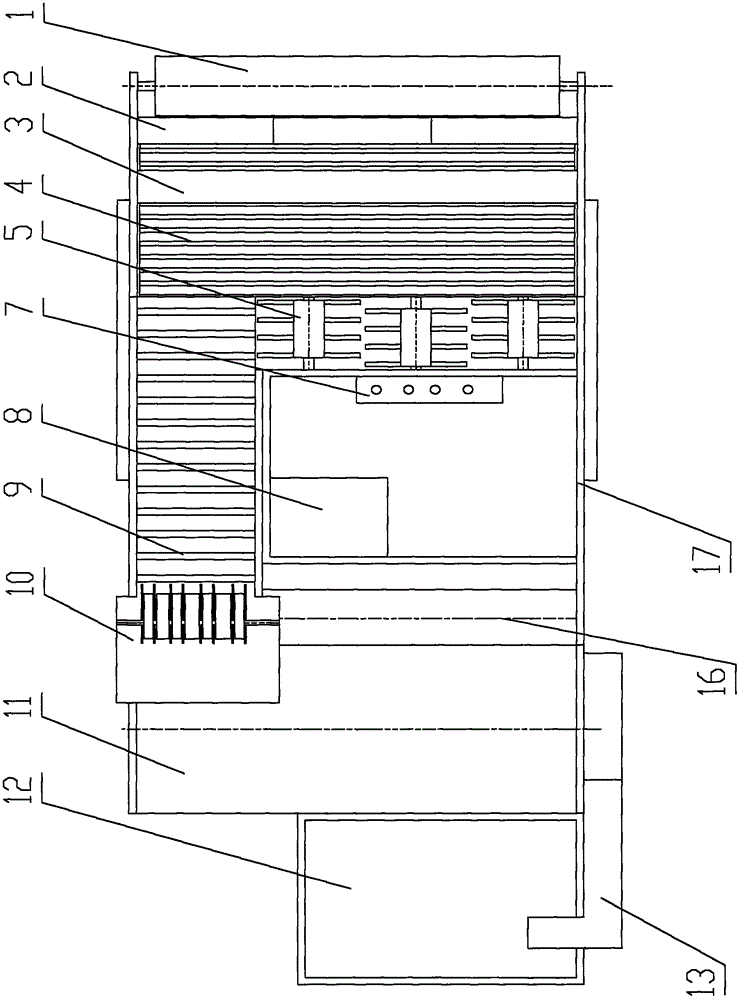

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] In the figure: 1. Depth limiting device 2, excavating device 3, soil crushing device 4, primary conveying device 5, secondary conveying device 6, lifting device 7, control device 8, engine 9, tertiary conveying device 10, fruit seedlings Picking device 11, fruit picking device 12, fruit storage box 13, lifting device 14, primary cleaning device 15, secondary cleaning device 16, fan 17, frame 18, crawler chassis

[0010] as attached figure 1 and figure 2 As shown, the self-propelled peanut combine harvester of the present invention includes a frame 17 installed on the crawler chassis 18, and a depth-limiting device 1, an excavating device 2, a soil breaking device 3, and a primary Conveying device 4, secondary conveying device 5, lifting device 6, tertiary conveying device 9, fruit seedling picking device 10, fruit picking device 11, fruit storage box 12, lifting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com