Motor driving device and driving method

A technology of motor drive and resistance, applied in the direction of DC motor speed/torque control, electrical components, control systems, etc., can solve the problems of complex circuits, high cost, and difficulty in popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

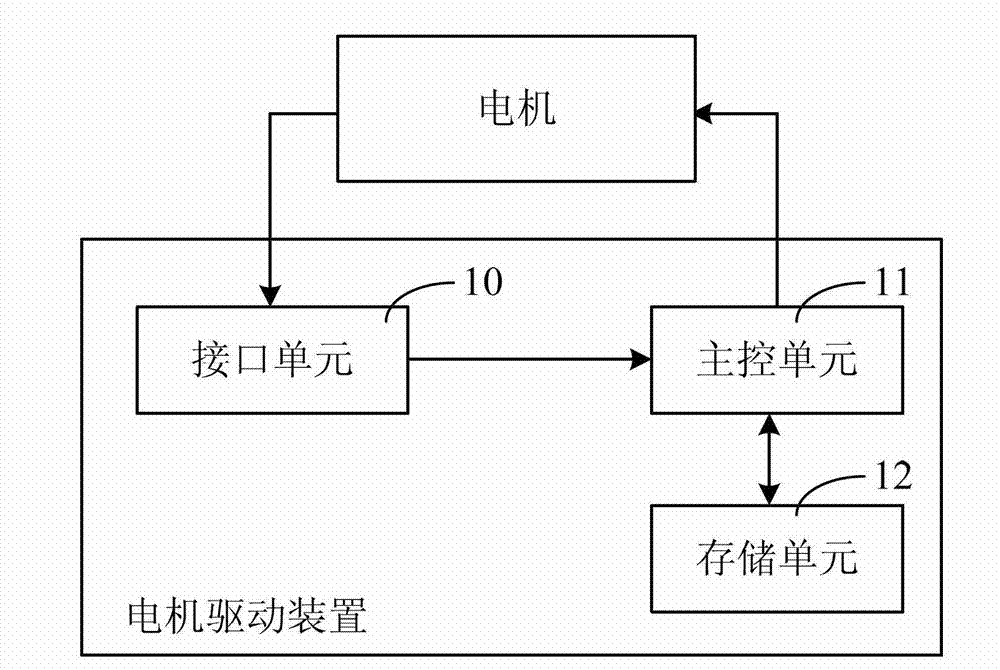

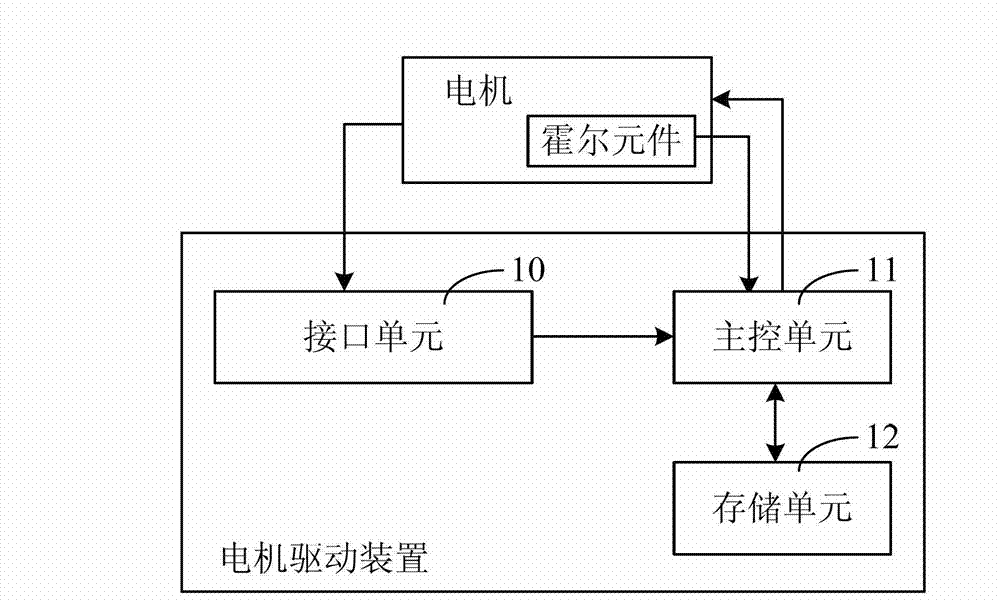

[0045] The specific implementation of the motor driving device and the driving method in the present invention will be described below with reference to the accompanying drawings. Such as figure 1 The schematic diagram of the principle of the motor drive device is shown. The motor drive device detects the models of different DDM motors, and matches the detected model with the driving parameters of the DDM motor stored in the motor drive device, and drives the DDM motor to run.

[0046] The motor drive device includes an interface unit 10 , a main control unit 11 and a storage unit 12 connected in sequence.

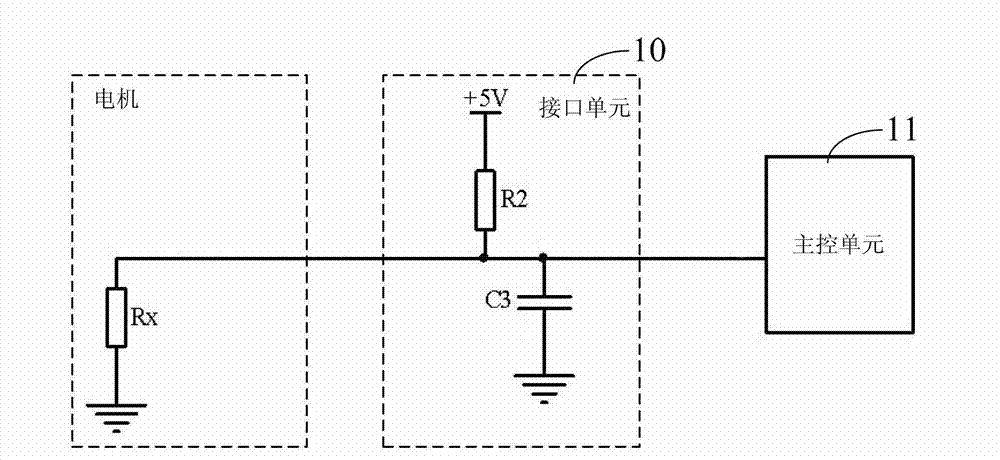

[0047] The interface unit 10 is used for detecting code information of motors of different models. Such as figure 2 What is shown is the first embodiment of the present invention. In this embodiment, the function of the interface unit 10 can be realized by a voltage divider circuit. The voltage dividing circuit includes a resistor R2 and a capacitor C3, wherein one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com