Full-closed cascading micro mechanical filter of micro shielding structure

A technology of shielding structure and filter, applied in the direction of waveguide type devices, electrical components, circuits, etc., to achieve the effect of reducing physical size, reducing microwave leakage, and enhancing clutter suppression capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

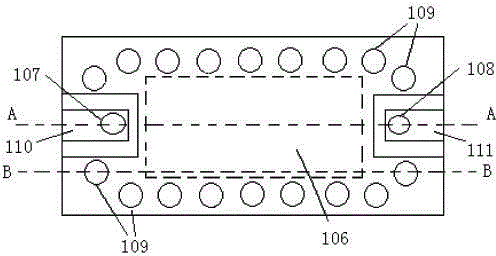

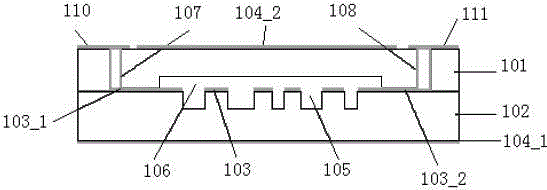

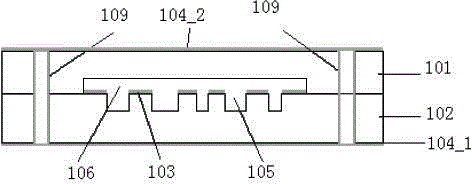

[0025] Example, combined with figure 1 , 2 , 3,

[0026] The embodiment of the present invention provides a micro-shielded, fully sealed, laminated micromechanical (MEMS) filter, which includes an upper substrate 101 and a lower substrate 102, and the upper substrate 101 is etched to form input through holes 107 and The output through hole 108 is used to integrate the upper substrate 101 and the lower substrate 102 of the filter through a micromechanical MEMS alignment bonding process;

[0027] The material of the upper substrate 101 is 400um high-resistance silicon, and the material of the lower substrate 102 is 400um high-resistance silicon; the upper surface of the lower substrate 102 is deposited with metal to form a microwave coupling line resonator 103, the lower substrate input signal interface transmission line 103_1 and the lower substrate Bottom output signal interface transmission line 103_2, deposit metal on the lower surface of the lower substrate 102 to form th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com