Thermal-insulating device of thermal control system of aerial camera

A technology of heat insulation device and thermal control system, which is applied in the direction of camera, camera body, optics, etc., can solve the problems of difficult control of heat loss of controlled components, reduce heat leakage rate of optical system, increase system time constant, etc. , to achieve adjustability, high reliability, and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

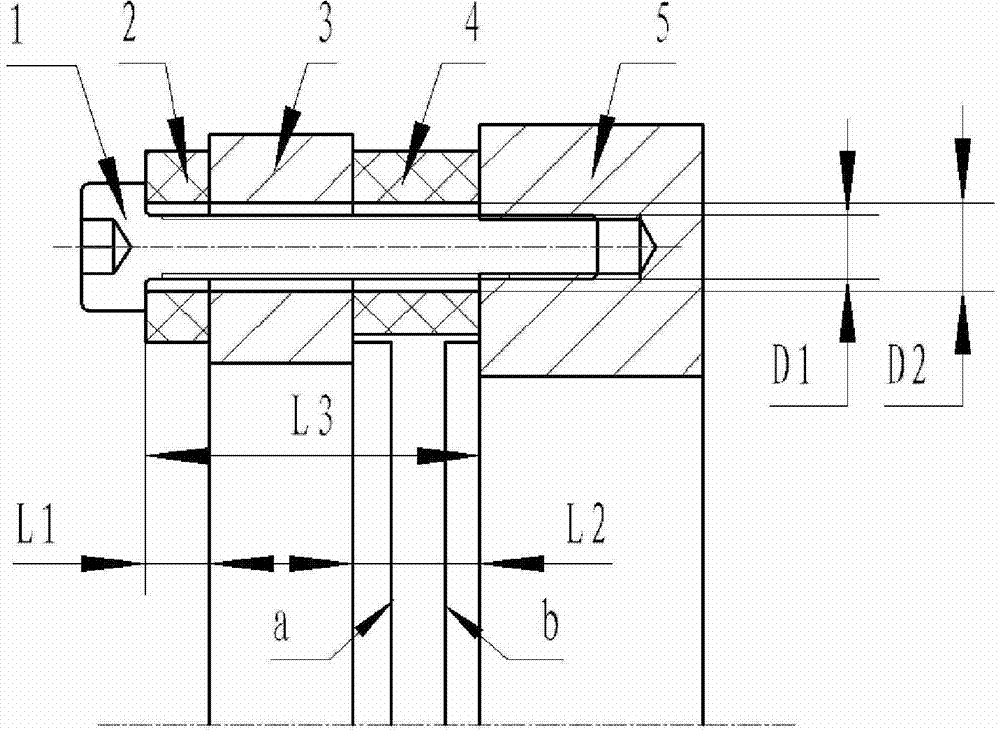

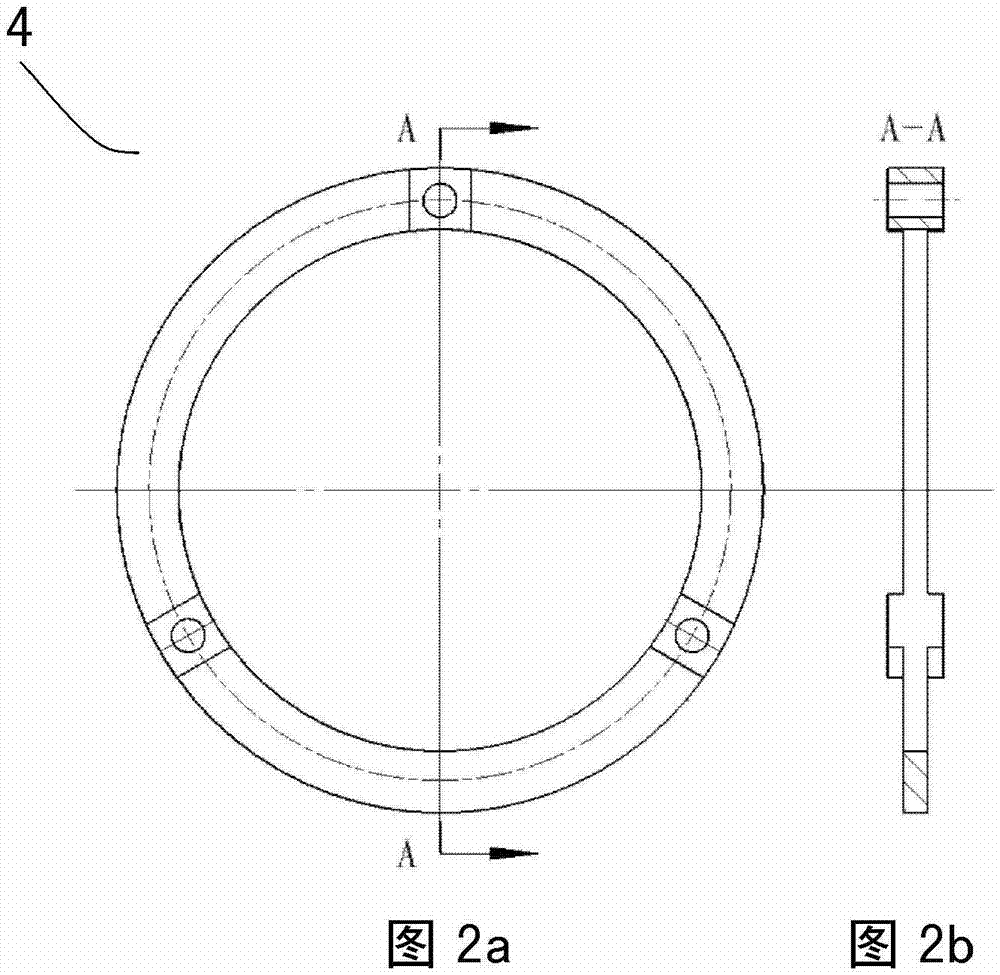

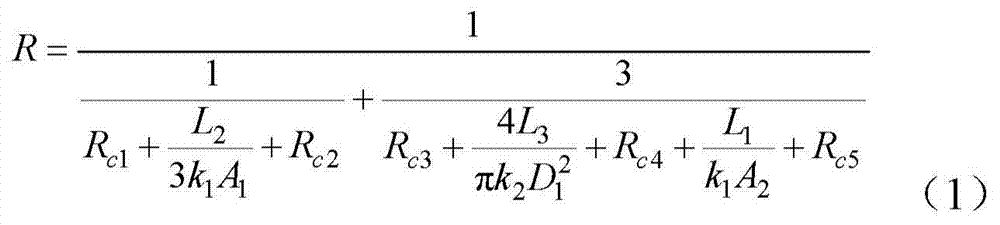

[0012] Such as figure 1 The heat insulation structure of the thermal control system of an aerial camera is shown, including three stainless steel screws 1, three heat insulation washers 2, and heat insulation pads 4, as well as the first structural member 3 and the second structural member 5, of which: 3 The stainless steel screw 1 and three heat insulating washers 2 are symmetrically distributed along the axial direction; the heat insulating pad 4 is located between the first structural member 3 and the second structural member 5; the heat insulating washer 2 is located in the ring of the stainless steel screw 1 Between the shape surface and the plane of the first structural member 3; the heat insulating gasket 2, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com