A small current clamp for on-site calibration of live measurement

A field calibration, current clamp technology, applied in the measurement of current/voltage, measurement of electrical variables, measurement devices, etc., can solve the problems of small operation space, inconvenient operators, irregularities, etc., to reduce the cross-sectional area of the magnetic circuit, The effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

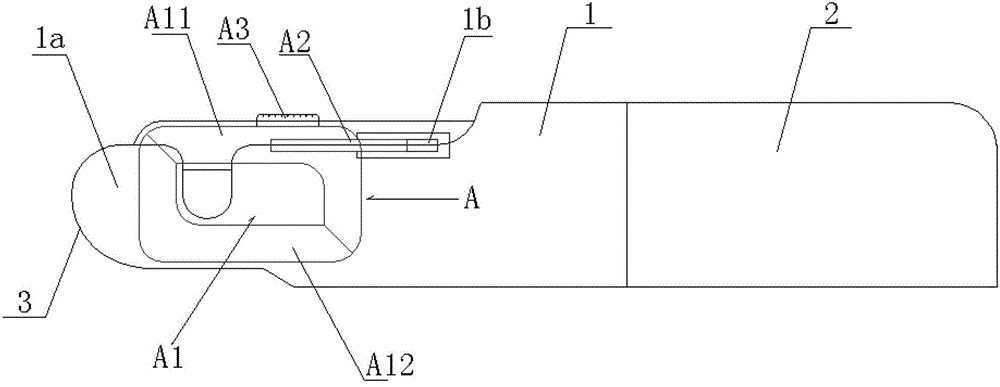

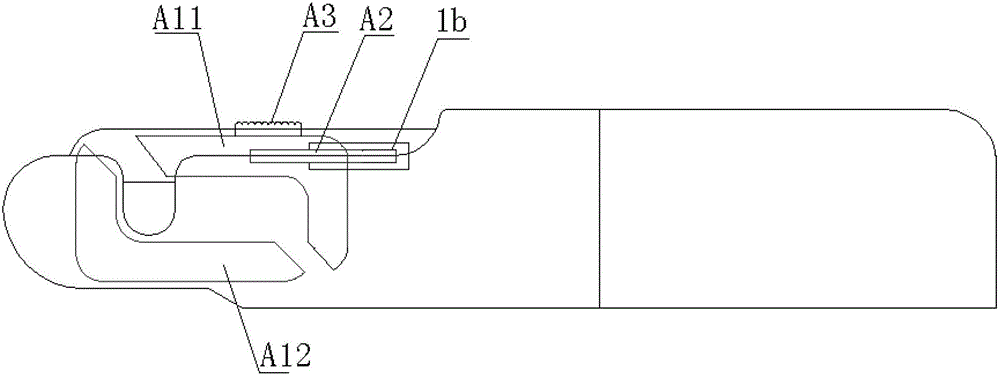

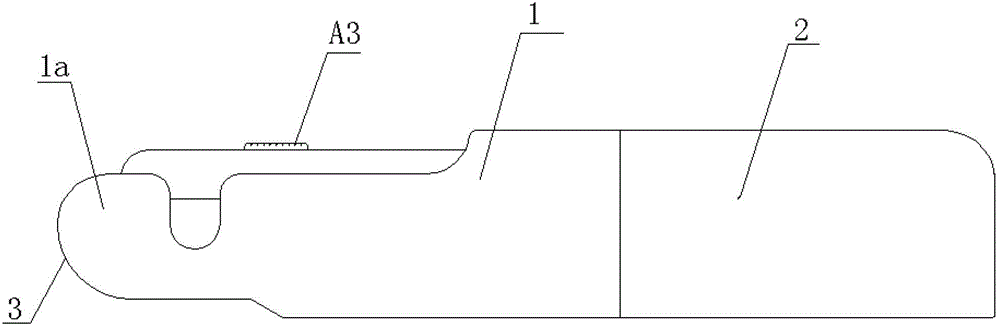

[0023] Such as figure 1 , figure 2 and image 3 As shown, a small-sized current clamp is used for on-site calibration of live measurement. One end of the current clamp body 1 is arranged in the clamp body jacket 2, and the other end of the current clamp body extends out of the clamp body jacket. The protruding current clamp body A clamp body potting 3 is provided at the clamp head 1a;

[0024] The middle part of the protruding end of the current clamp body 1 is provided with a body slideway 1b in the same direction as the body;

[0025] The inside of the current clamp head 1a is provided with a measuring magnetic core assembly A that can move left and right along the slideway of the clamp body.

[0026] The small current clamp used for on-site verification of live measurement of the present invention changes the winding space position of the secondary winding wound on the current clamp magnetic core (magnetic circuit) in the prior art, and changes the working position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com