Gas rotary joint

A technology of rotary joints and inflatable joints, applied in the direction of pipe elements, etc., can solve problems such as the inability to ensure that the inflating path and the vacuuming path are parallel and evenly surrounding the rotating mechanism, leakage, lack of inflatable and vacuuming fusion, etc., to achieve enhanced sealing The effect of stability, simple connection and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

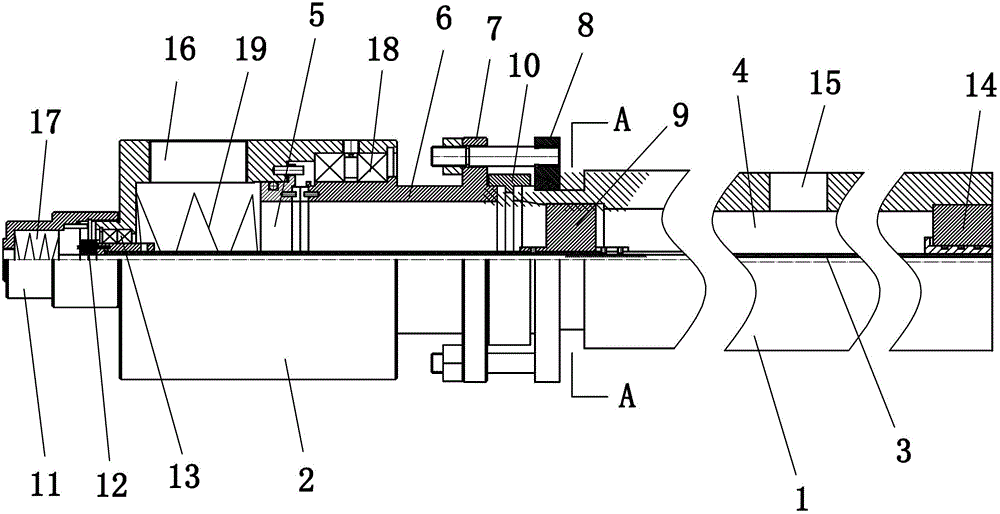

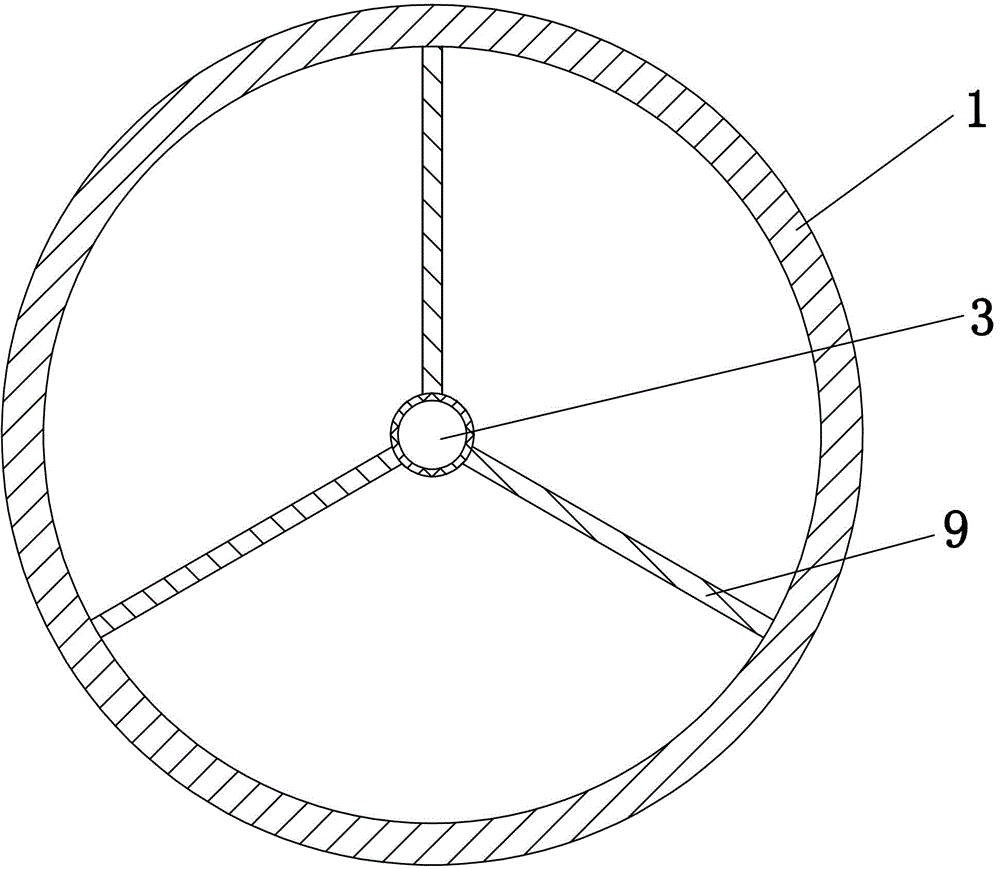

[0019] Embodiment 1: as figure 1 , 2 As shown, a gas rotary joint includes a rotary main shaft 1 and a joint main body 2, and the rotary main shaft 1 and the joint main body 2 are located on the same axis. The interior of the rotating spindle 1 is hollow with a first vacuum chamber 4, the joint body 2 includes a shell, and the inside of the shell has a second vacuum chamber 5, and a vacuum interface 16 is opened on the joint body 2, and the vacuum joint 16 is connected to the inside of the joint body 2. The second vacuum chamber 5 is connected; a vacuum outlet 15 is opened on the rotating main shaft 1 , and the vacuum outlet 15 is connected to the first vacuum chamber 4 inside the rotating main shaft 1 . A fixed connecting sleeve 6 is installed at one end of the joint body 2 close to the rotating main shaft 1, and the end of the fixed connecting sleeve 6 away from the rotating main shaft 1 is located inside the joint main body 2, and the fixed connecting sleeve 6 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com