Cable twisting prevention connecting device for high-power fan

A connection device, high-power technology, applied in wind turbines, wind turbine components, motors, etc., can solve the problems of cable breakage, high cost, twisted cable faults of high-power fans, etc., and achieves low contact resistance, low manufacturing cost, The effect of preventing twisting of the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

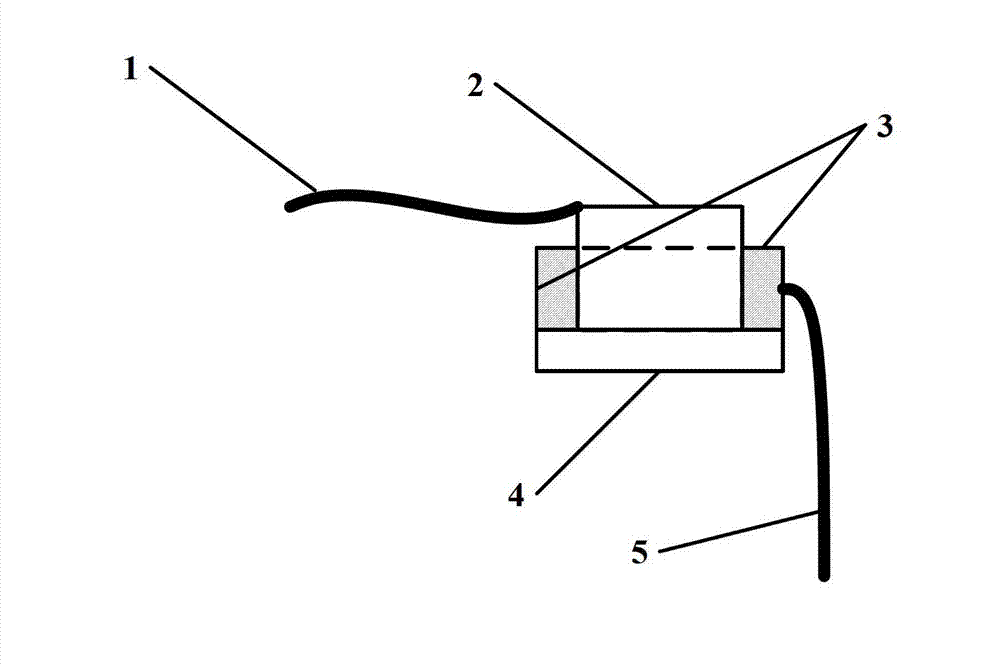

[0016] Please refer to figure 1 , a high-power fan anti-twist cable connection device is shown in the figure, including: engine room cable 1, engine room collector rotating shaft 2, tower collector ring 3, engine room collector turntable 4 and tower cable 5; :

[0017] The nacelle cable 1 is connected to the side of the nacelle power collecting rotating shaft 2, the nacelle power collecting rotating shaft 2 is placed in the inner ring of the tower collecting ring 3, and the side of the outer ring of the tower collecting ring 3 is connected to the tower cable 5, The nacelle collector rotating disk 4 is concentrically installed on the bottom surface of the nacelle collector rotating shaft 2, and the upper end surface of the nacelle collector rotating disk 4 protruding from the nacelle collector rotating shaft 2 is in close contact with the bottom surface of the tower collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com