Sand preventing device

A sand control and body technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of sand control measures once and for all, reduce the number of workover operations, avoid sand sticking of pump valves and pistons, and reduce wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

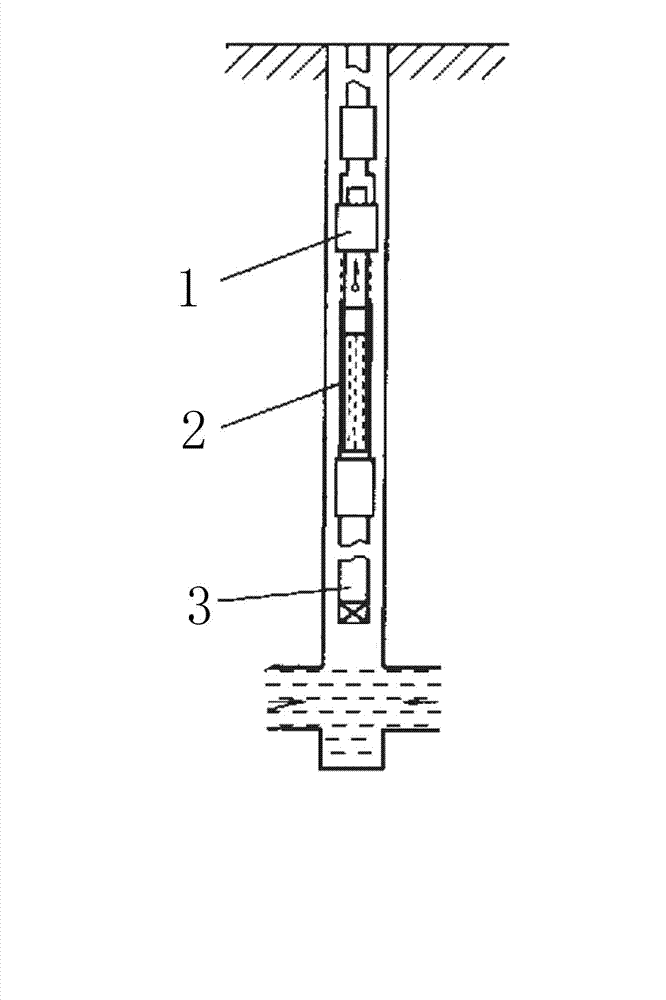

[0009] A sand control device according to the present invention includes a hollow cylindrical body 1, the upper part of the body 1 is provided with a joint 2, and the lower part of the body 1 is provided with a pocket string 3, and the feature is that the body 1 is provided with several filter holes , the lower surface of the pocket column 3 according to the present invention is also provided with several filter holes.

[0010] When in use, the sand control device of the present invention is arranged at the lower part of the oil well pump through the joint 2, and the well fluid is reversed by using the oil well pump. Stay inside the body 1 and fall into the pocket string 3 under the action of gravity, and the residual well fluid in the pocket string 3 will be removed from the filter screen at the lower part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com