Shallow-buried karst cave filing construction method and shallow-buried karst cave filing construction structure

A construction method and technology of karst caves, applied in filling, infrastructure engineering, construction, etc., can solve problems such as long project investment time, environmental protection hazards, environmental hazards, etc., achieve significant economic and environmental advantages, wide application range, The effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

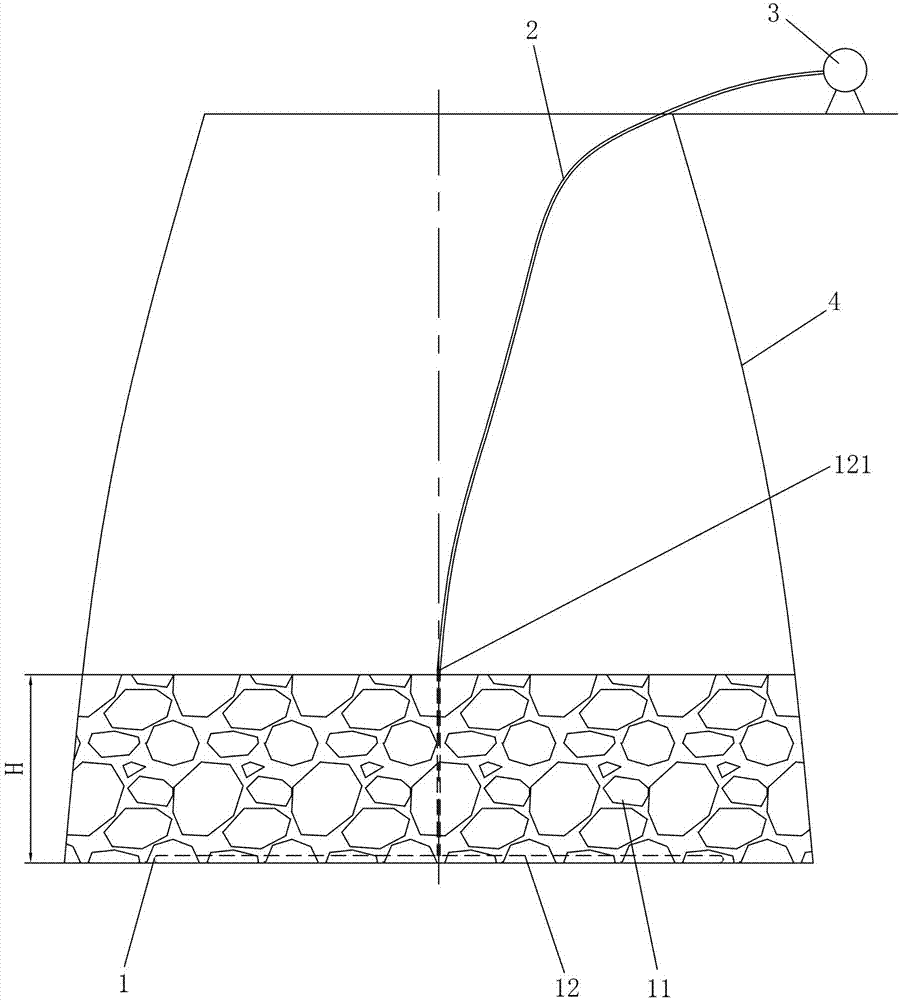

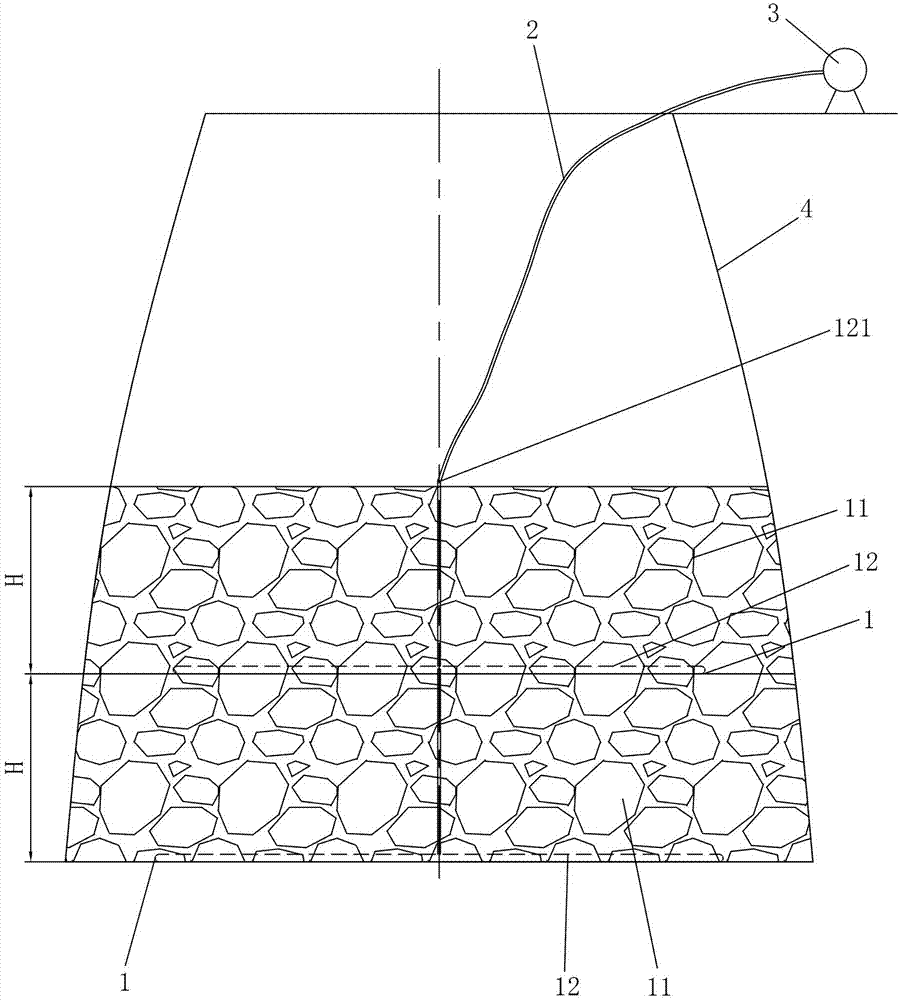

[0031] Such as Figure 1 to Figure 9 Shown, certain shallow buried karst cave 4 deep 8m, bottom diameter 8m, top diameter 5m, when adopting shallow buried karst cave filling construction method of the present invention to carry out construction, comprise the following steps,

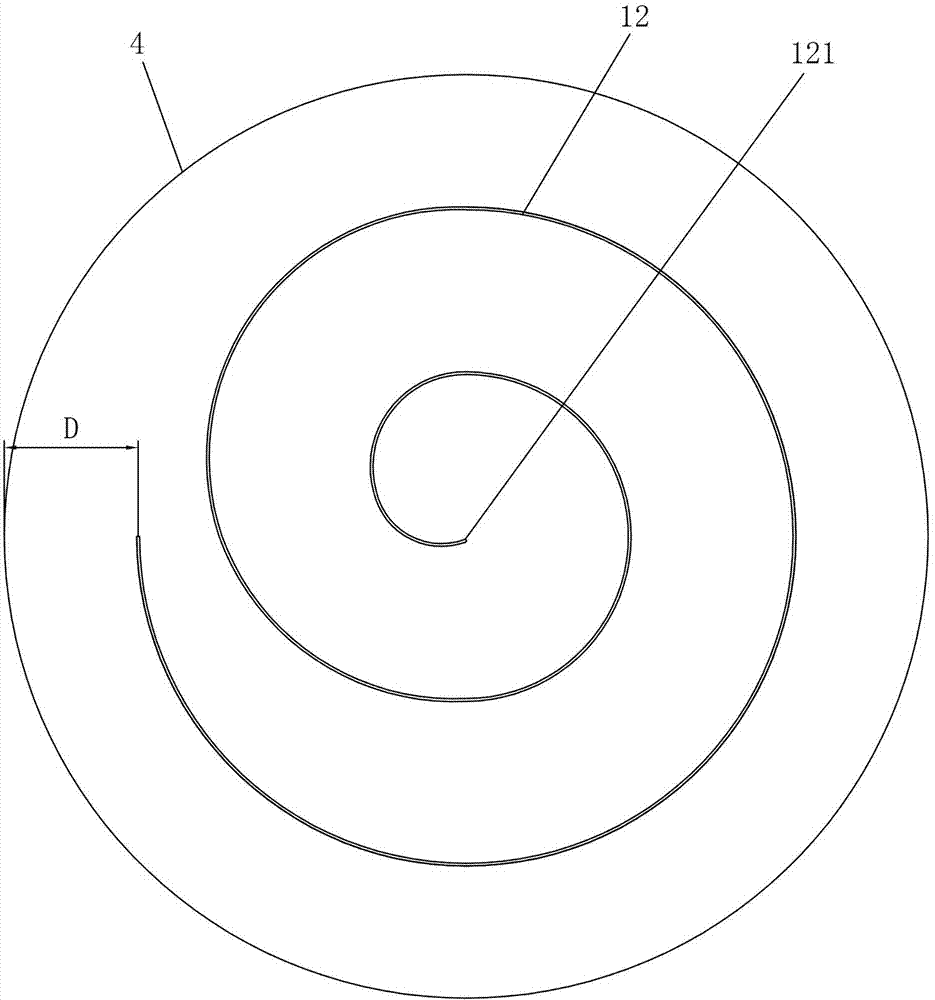

[0032] (1) Prefabricated grouting pipe 12, using a high-performance composite pipe, one end of the composite pipe is sealed, the other end is used as the grout inlet 121, and multiple grout outlets 122 are drilled on the pipe wall of the composite pipe (see Figure 9 ).

[0033] (2) if figure 1 As shown, first the prepared grouting pipe 12 is arranged at the bottom of the shallow cave 4, and then the earth-rock mixed filler is filled above the arranged grouting pipe 12. The earth-rock mixed filler can be obtained locally, and the particles of the earth-rock mixed filler There is no special requirement for the diameter. When filling, it is directly poured from the top of the shallow cave 4, and then art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com