Technology and equipment for preparing C/C composite

A composite material and process technology, which is applied in the field of preparation of C/C composite materials and its equipment, can solve the problems of low material densification rate, slow gas transmission, and difficult industrialization, so that it is less difficult to achieve industrialization and avoid invalid reactions , The effect of short densification period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Device embodiment

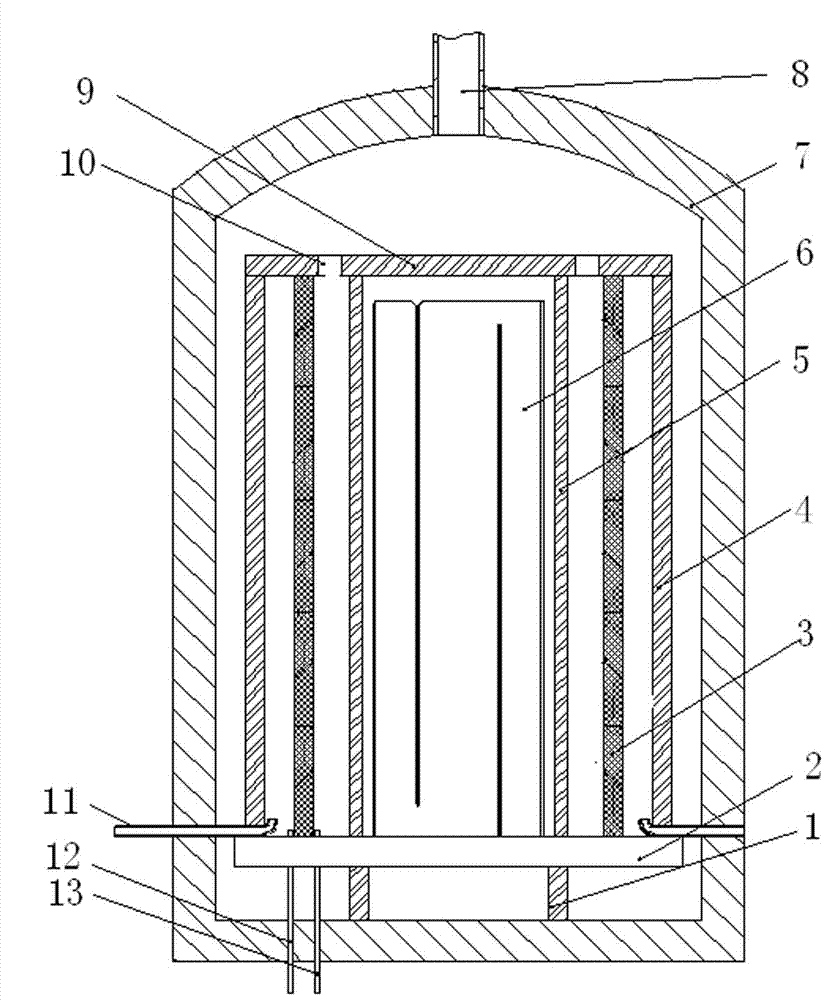

[0029] Referring to the accompanying drawings, the embodiment of the equipment for preparing C / C composite materials in the present invention includes a furnace shell, a heating element 6, and a prefabricated body 3. An air inlet 8 is provided above the furnace shell, and an insulating layer 7 is provided on the inner wall of the furnace shell , the inner and outer thermocouples 13 and outer thermocouples 12 for measuring the temperature of the inner and outer sides of the prefabricated body 3 are respectively provided on the inner and outer sides of the prefabricated body 3, which are used to detect the temperature gradient formed in the thickness direction of the prefabricated body 3, and also include inner tooling 5, The outer tooling 4 and the cover plate 9, the inner tooling 5 is placed inside the prefabricated body 3, the inner tooling 5 is placed outside the heating body 6, the outer tooling 4 is placed outside the preformed body ...

Embodiment 2

[0033] Embodiment 2: preparation process embodiment ①

[0034] The embodiment of the process for preparing cylindrical C / C composite materials in the present invention includes the following steps:

[0035] (1) Preform 3 pretreatment: make the density 0.5 g / cm 3 , A cylindrical 2.5D carbon fiber preform 3 with a size of Φ660mm×Φ600mm×300mm is placed in a high-temperature furnace, and subjected to high-temperature pretreatment at 1800°C for 2 hours;

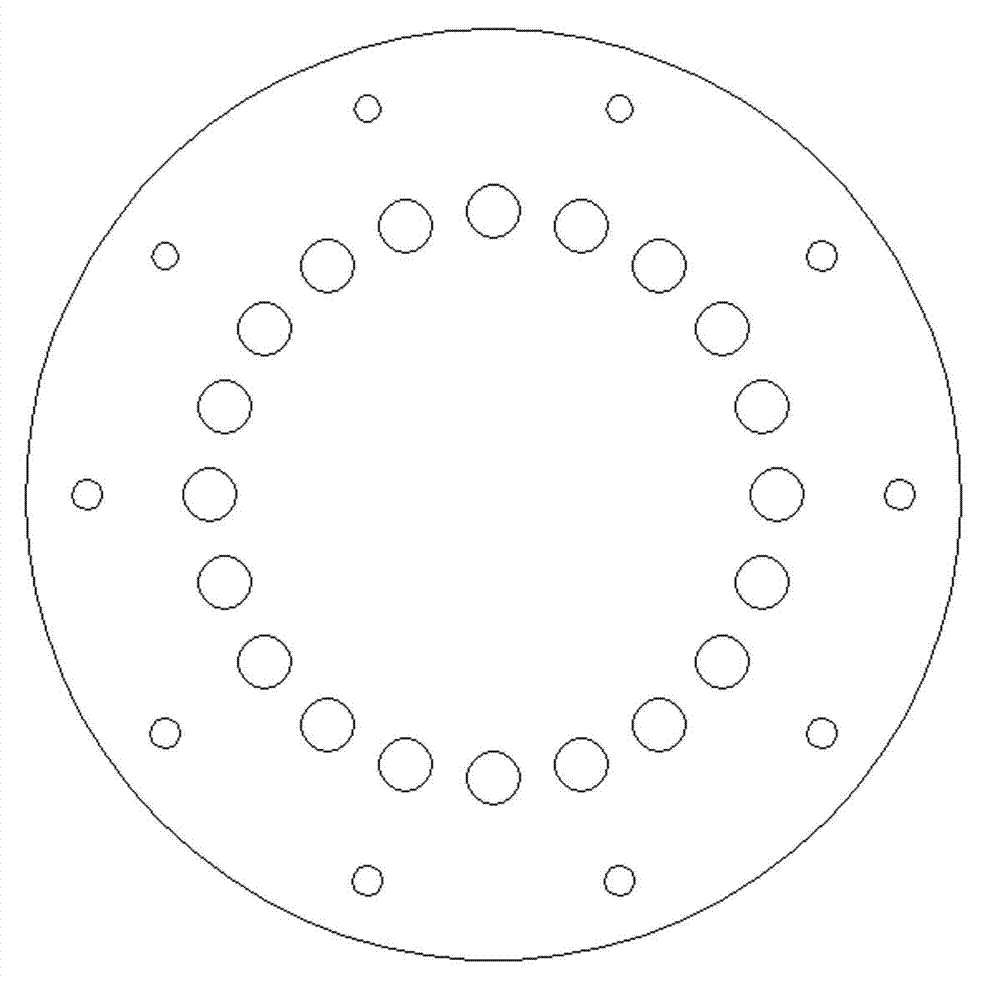

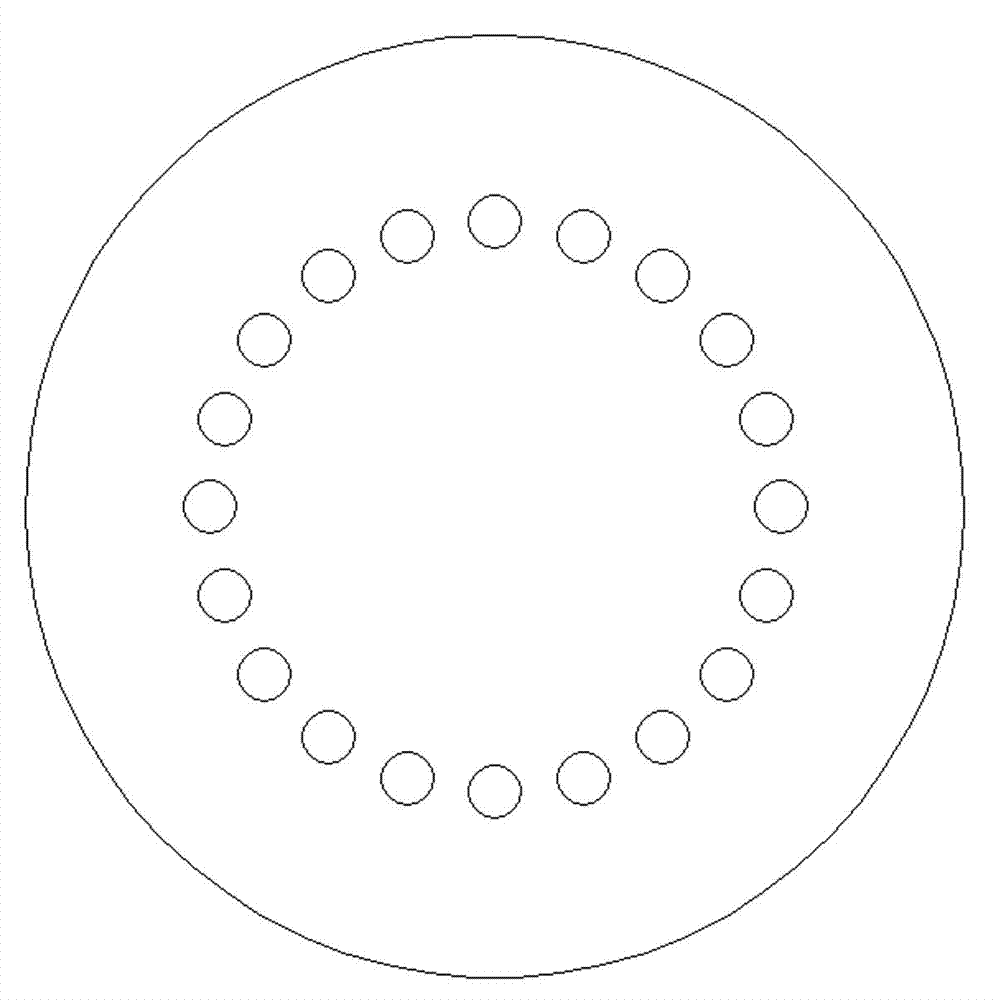

[0036] (2) Tooling preparation: According to the shape and size of the prefabricated body 3, process the heating element 6, the outer tooling 4, and 7 pieces of the prefabricated body 3. In the area corresponding to the space formed by the inner tooling 5 and the prefabricated body 3, there are 20 holes with a diameter of 30mm. In the area corresponding to the space formed by the outer tooling 4 and the prefabricated body 3, there are 10 cover plates 9 with a diameter of 18mm air extraction holes 10, a material carrier plate 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com