Anaerobic reactor

An anaerobic reactor and tank body technology, applied in the field of anaerobic reactors, can solve the problems of small sludge volume load, high concentration of suspended solids in the effluent, and low processing capacity, and achieve uniform water distribution and low concentration of suspended solids in the effluent , the effect of strong processing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

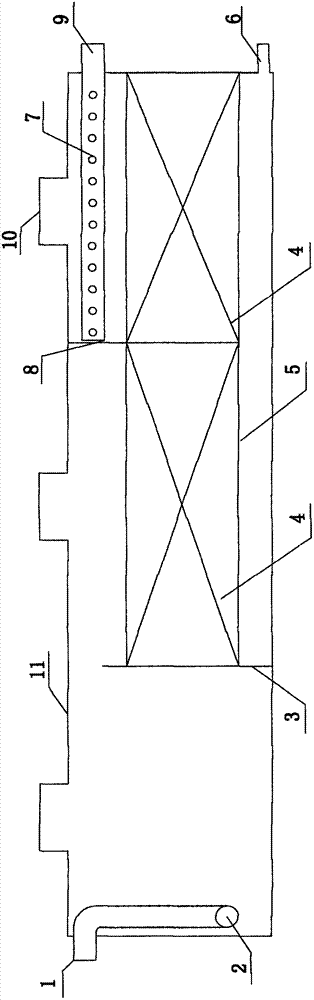

[0021] The main purpose of the conception of the present invention is to solve the problem of inhomogeneous distribution of influent and effluent water, anaerobic sludge deposition at the bottom of the tank and sludge in the prior art, which only exist to filter sewage through baffles and anaerobic fillers. The disadvantages of small volume load, low processing capacity, and high concentration of suspended solids in the effluent. The present invention solves the above-mentioned problems by adding a water distribution plate and a mud discharge pipe on one side of the water drop partition.

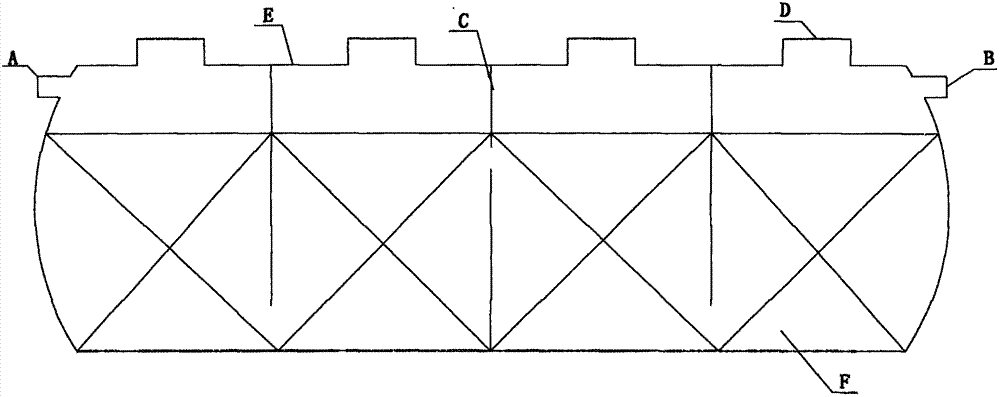

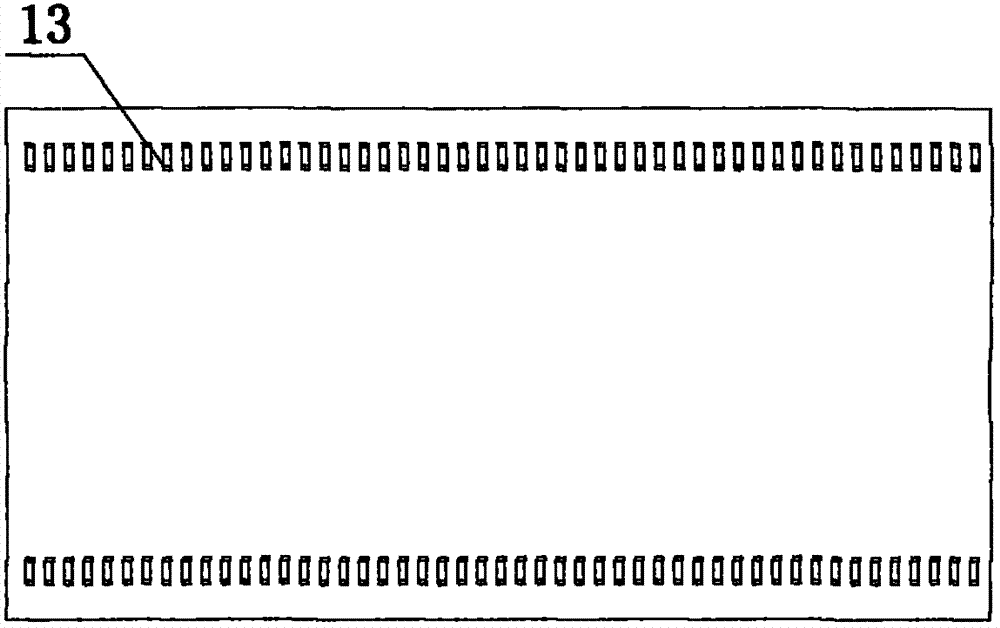

[0022] Such as Figure 2-4 Shown, specifically, the technical scheme that the present invention adopts is to provide a kind of anaerobic reactor, and it comprises tank body 11, anaero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com