Automatic trigger broken belt capturing device for belt conveyer

A broken belt catching device and belt conveyor technology, applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of belt impact damage, secondary belt damage, unreliable triggering, etc. The effect of smooth braking process, reliable work and safe and reliable action process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

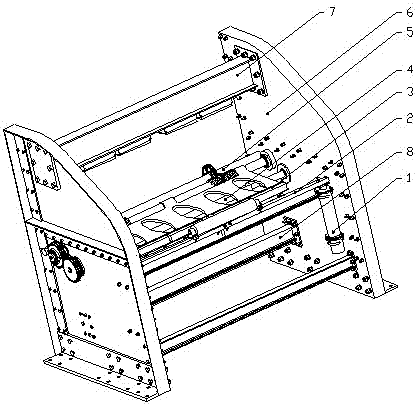

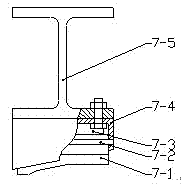

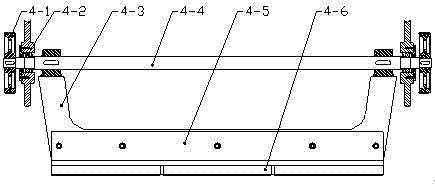

[0028] Such as figure 1 with figure 2 As shown, the belt conveyor of the present invention uses an automatic triggering and catching device, mainly consisting of a trigger mechanism 1, a carrying mechanism 2, an upper braking mechanism 3, a lower braking mechanism 4, a moment loading mechanism 5, a frame side plate 6, The upper brake beam mechanism 7, the lower brake beam mechanism 8, the locking mechanism 9 and the crossbeam 10 constitute. Wherein the frame is composed of two frame side plates 6 connected by a plurality of crossbeams 10, the upper brake mechanism 3 is installed in the middle of the frame, the trigger mechanism 1, the carrying mechanism 2 and the locking mechanism 9 are installed in the front of the upper brake mechanism 3, and the rear is installed There is a torque loading mechanism 5, a lower brake mechanism 4 is installed below, an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com