Hillstone fiber handicraft picture and manufacturing method thereof

A technology of fiber technology and manufacturing method, applied in the field of mountain stone fiber craft painting and manufacturing, to achieve the effect of beautiful fading and not easy to fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The production process is divided into the following steps:

[0014] A. Preparation of raw materials

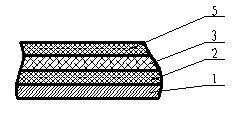

[0015] Select stones with traces on the surface, and polish them to the appropriate size. The thickness of the stone is 2-2.5mm, the height is 5-20mm, and the width is 5-10mm. Choose top-grade five-plywood or ten-plywood or wood board that is not broken, flat and smooth as the bottom plate 1, and the white background is the best. Rinse the selected green sand with water several times. Choose natural tree bark that has been infused. Choose silk or dyed fiber materials with bright colors.

[0016] B. Making the drawing background

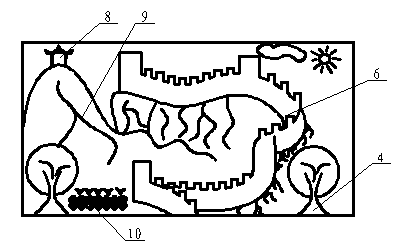

[0017] Use a brush to spread the base color acrylic paint as the primer layer 2 on the base plate 1 with uniform strength and no brush marks. Then, after 5-7 hours of drying in the shade, use various acrylic paints and acrylic blending oil to make a moderate , Paint on the required locations such as mountains, water, fog, and then draw the outline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com