Manipulator fixture

A technology of manipulators and fixtures, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as workpiece falling off, operator safety threats, and affecting production efficiency, and achieve the effects of strengthening retention, avoiding personal injury, and improving work efficiency

Active Publication Date: 2015-12-02

SHANGHAI TONGLING AUTOMOTIVE TECH INC

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, since the suction cup uses the pressure difference with the outside world to hold the workpiece

When the workpiece is large or heavy, the requirements for the quality of the pressure device and the suction cup are very high. Once the pressure difference is insufficient or the suction cup is damaged, the workpiece will fall off, affecting production efficiency and threatening the safety of the operator.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

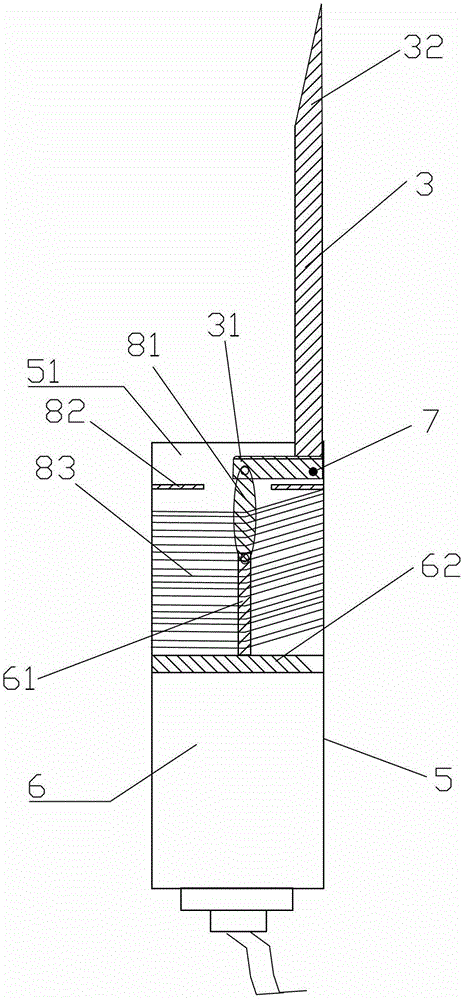

[0033] The difference between this embodiment and Embodiment 1 is that the cylinder is a two-way cylinder. In this embodiment, the spring 93 and the stop plate 82 are not provided. Utilize the piston rod of two-way air cylinder to drive pressure rod 3 to reciprocate and rotate. All the other structures and methods of use are the same as in Example 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

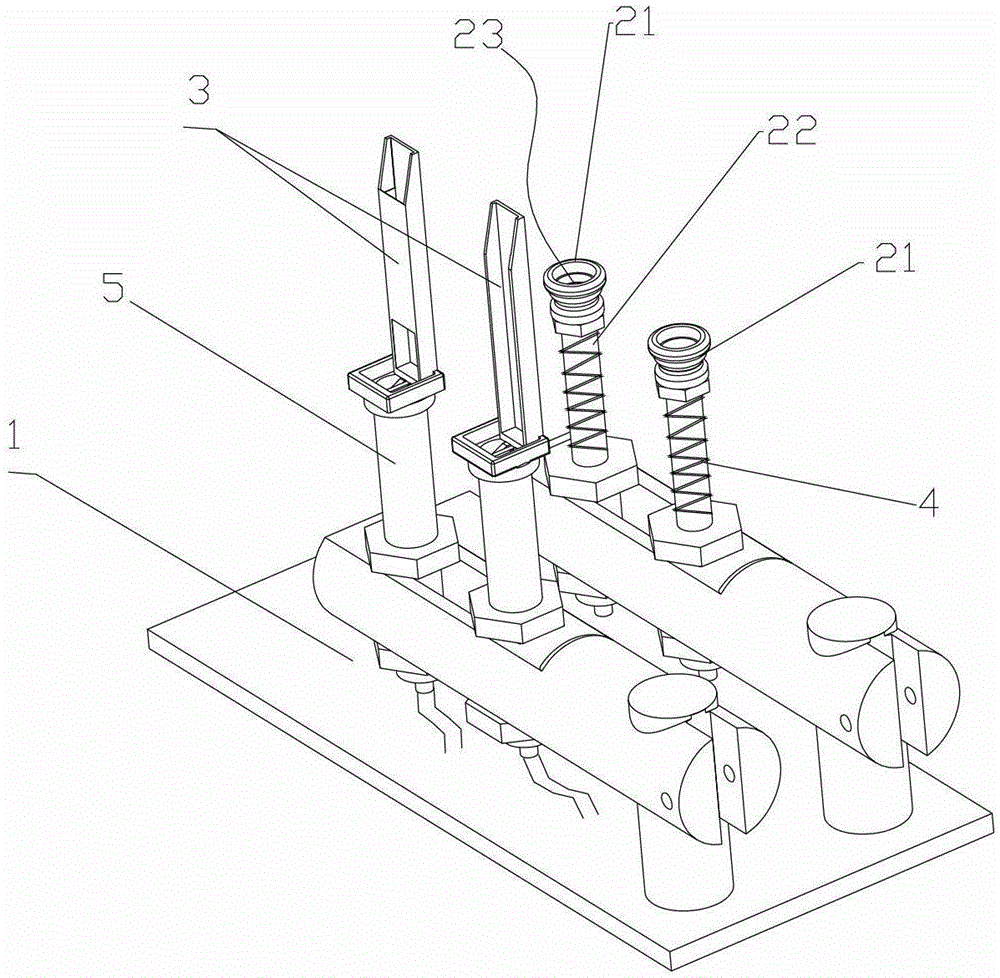

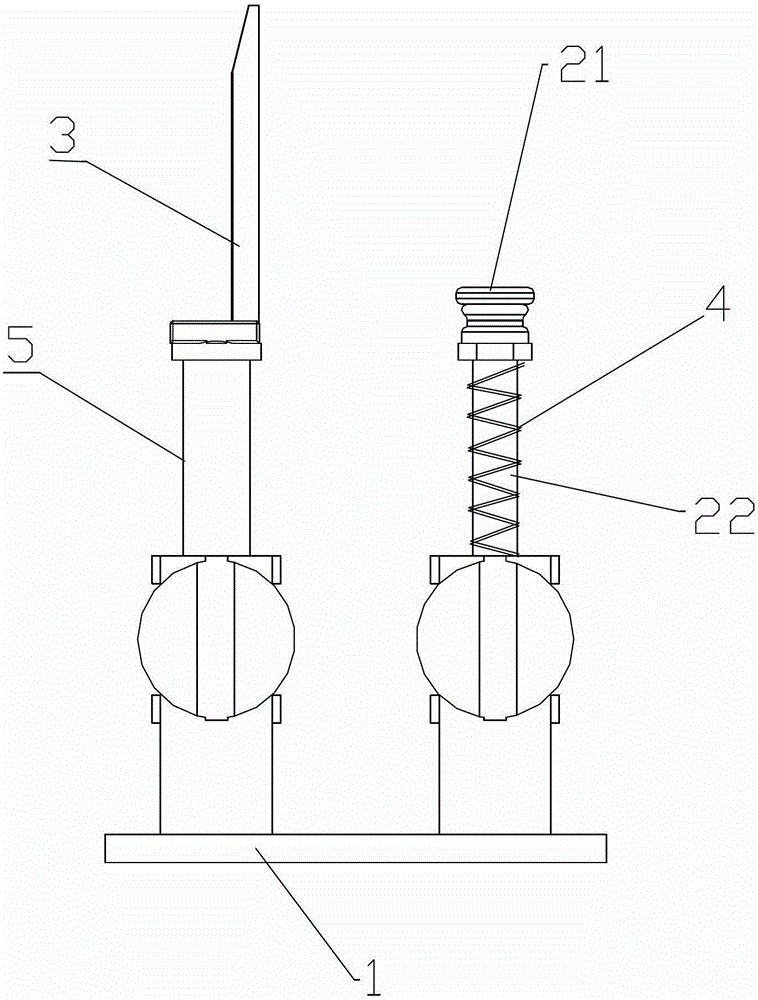

The invention discloses a manipulator clamp which includes a base, compressing device and a suction device capable of sucking workpieces. The suction device and the compressing device is arranged on the base. The compressing device can be movably arranged and after moving, the compressing device and the suction device clamp the workpieces together. The manipulator clamp is additionally provided with the compressive rods which match with the suction device and the compressive rods and the section device clamp the workpieces together. By suction and clamping force, the workpiece are fixed to strengthen retaining force to the workpieces so as to prevent the workpieces from loosening during the clamping process, prevent the falling workpieces from injuring operating persons and improve the working efficiency.

Description

technical field [0001] The invention relates to a gripper for a manipulator. Background technique [0002] The manipulator can imitate certain motion functions of the human hand and arm, and is used to grab, carry objects or operate automatic operating devices according to a fixed program. The manipulator is the earliest industrial robot and the earliest modern robot. It can replace human heavy labor to realize the mechanization and automation of production, and can operate in harmful environments to protect personal safety, so it is widely used in machinery manufacturing, metallurgy, electronics, light industry and atomic energy and other departments. In the production process of automotive interior parts, it is necessary to handle and move the interior parts. The commonly used tools for handling and moving interior parts are suction cups, which are used to hold workpieces and carry them. [0003] However, because the suction cup uses the pressure difference with the out...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B25J15/00

Inventor 项建武李佳

Owner SHANGHAI TONGLING AUTOMOTIVE TECH INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com