Hob mounting structure

A mounting structure and hob technology, which is applied in the direction of milling cutters, metal processing equipment, milling machine equipment, etc., can solve the problem of inability to eliminate the gap between the inner hole of the hob and the mandrel, the cumulative error of the chip flute, and the failure to use Requirements and other issues, to meet the accuracy, reduce tooth profile error, and ensure the effect of sharpening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

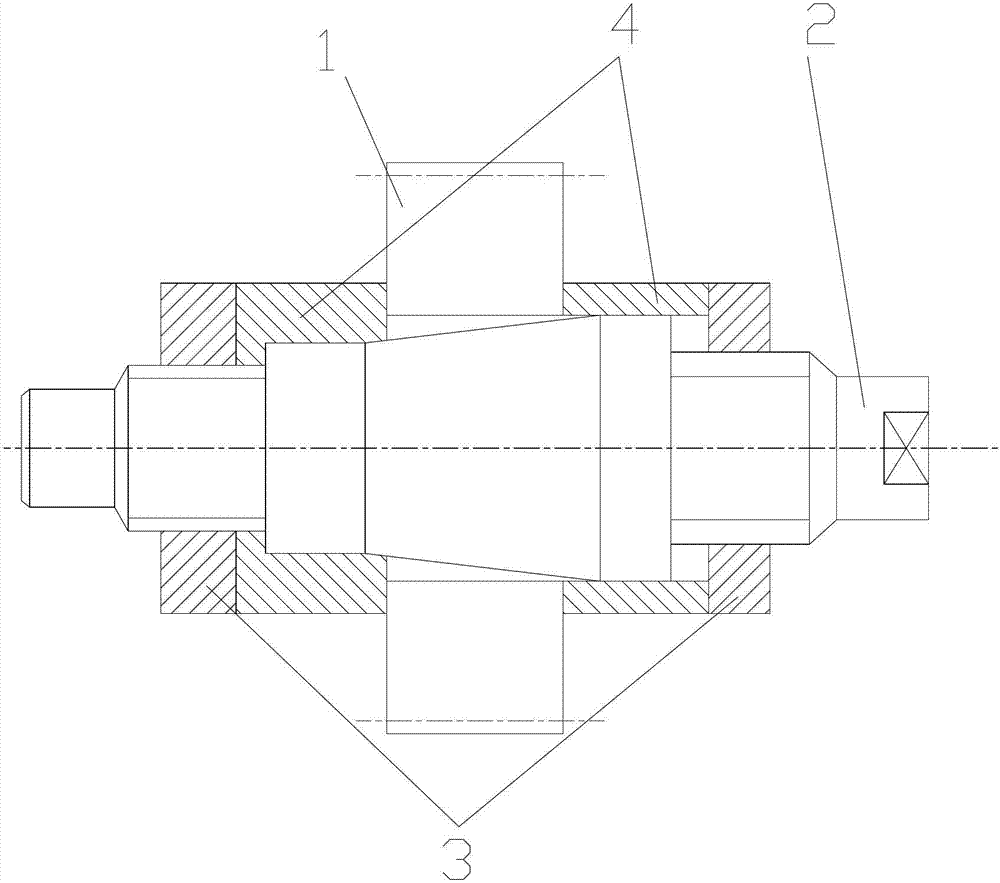

[0011] attached figure 1 It is a hob installation structure according to the present invention, which includes a hob 1 and a tapered mandrel 2; the inner hole of the hob 1 is installed on the tapered mandrel 2; The tapered mandrel 2 is fixed; a positioning pad 4 is also provided between the hob 1 and the nut 3 .

[0012] When using the improved tapered mandrel 2 to clamp the hob 1, first install the hob 1 into the conical surface of the tapered mandrel 2, push it tightly by hand, turn the right end nut 3, and push the right positioning pad 4 and The right end of the hob 1 is in contact, then the nut 3 on the left is turned, and the positioning pad 4 at the left end is pushed to press the hob 1 tightly.

[0013] The solution of the present invention uses the tapered mandrel 2 to position the inner hole of the hob 1 to eliminate the fit gap between the inner hole of the hob 1 and the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com