Edible instant cassava powder and preparation method thereof

A cassava flour and instant technology, which is applied in the field of food processing, can solve the problems of nutrient loss and other problems, achieve the effect of improving taste, increasing productivity, and promoting whole-food nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1, the production process parameter optimization of edible cassava flour

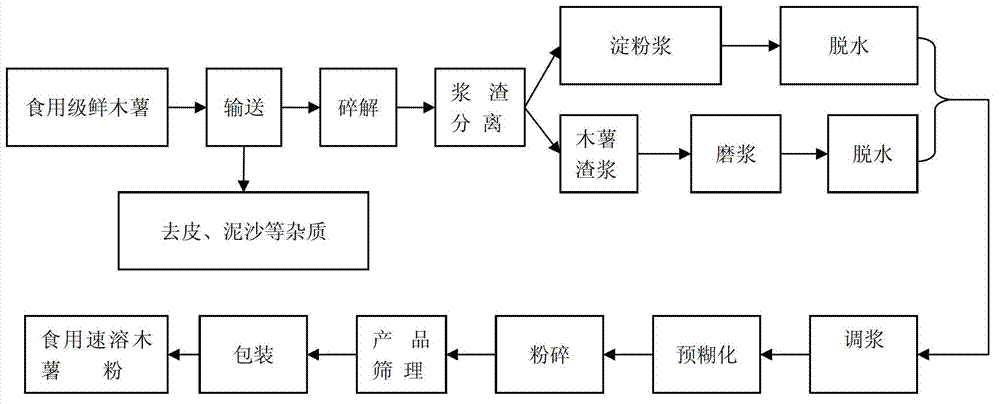

[0059] The process of the preparation method is as follows figure 1 shown.

[0060] 1. Raw material preparation

[0061] Cassava is a root crop with a rough surface and a large number of lenticels. The lenticels cannot open and close freely, which accelerates the exchange of water. The water content of edible fresh cassava decreases continuously during storage. The dry powder content of fresh cassava decreased mainly due to respiration and water loss. The shelf life of cassava is very short, and it is generally believed that postharvest physiological deterioration will occur after 24 to 48 hours after harvest. Fresh cassava after harvest is susceptible to physiological diseases such as root soft rot, root dry rot and postharvest root rot, which seriously affect product quality.

[0062] Table 2 Comparison table of moisture, starch content and rot rate changes of fresh cassava

[0...

Embodiment 2

[0118] Embodiment 2, preparation and product performance of edible instant cassava flour

[0119] (1), preparation of edible instant cassava flour

[0120] (1) The edible cassava raw material (8 hours) that will be harvested to the processing factory, the starch content of fresh cassava is 28%.

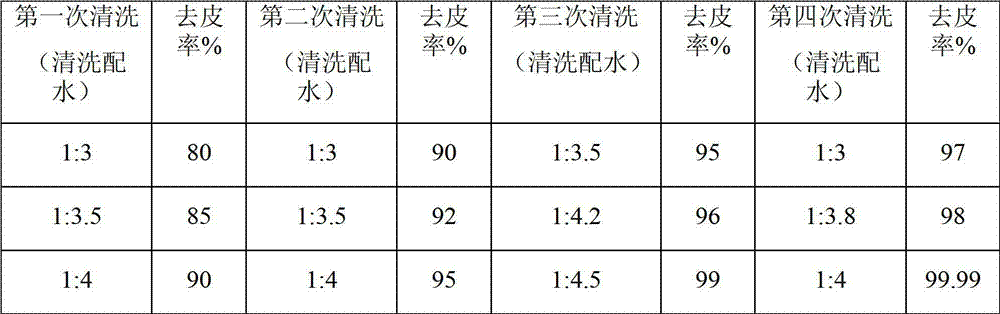

[0121] (2) After the first and second washings of the fresh cassava obtained in step (1) (fresh cassava: process water =) 1: 3.5;), the third washing is performed, using fresh water, and the washing water ratio is 1: 4.2; Fresh water is used for the fourth washing, and the washing water ratio is 1:3.8;

[0122] (3) The cleaned raw materials obtained in step (2) are used as the medium, and the water ratio of fresh cassava raw materials and water is 1:1.2, and the crushed cassava is processed into puree. The passing rate of the primary pulverized material through the hole diameter of Φ25mm is 100%. The fineness of the secondary pulverized material passes through a 60-mesh aperture wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com