Hand-push multi-line continuous seeding and dibbling machine for peanuts

A hand-push, peanut technology, applied in the direction of interval-type quantitative seeding machinery, etc., can solve the problems of irregular size and shape, bulky body, difficult to turn, etc., and achieve the effect of low possible vacancy performance, light weight and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The device of the present invention will be further fully described below with reference to the accompanying drawings.

[0019] figure 1 There are many anti-skid teeth (15) on the circumference of the circular running wheel (1), so that the running wheel can walk in the soil ditch stably and without error. When the hand-push peanut multi-row seeding point machine of the present invention is sowing, the distance between the seeds can be divided into sections on the circumference of the walking wheel: the circumference of the walking wheel should be divided into several sections, and the circumference should be divided into several sections. For several sections, insert several pulling rods (8) horizontally on the side of the wheel. These pulling rods are evenly distributed on the inner circle of the side of the walking wheel. .

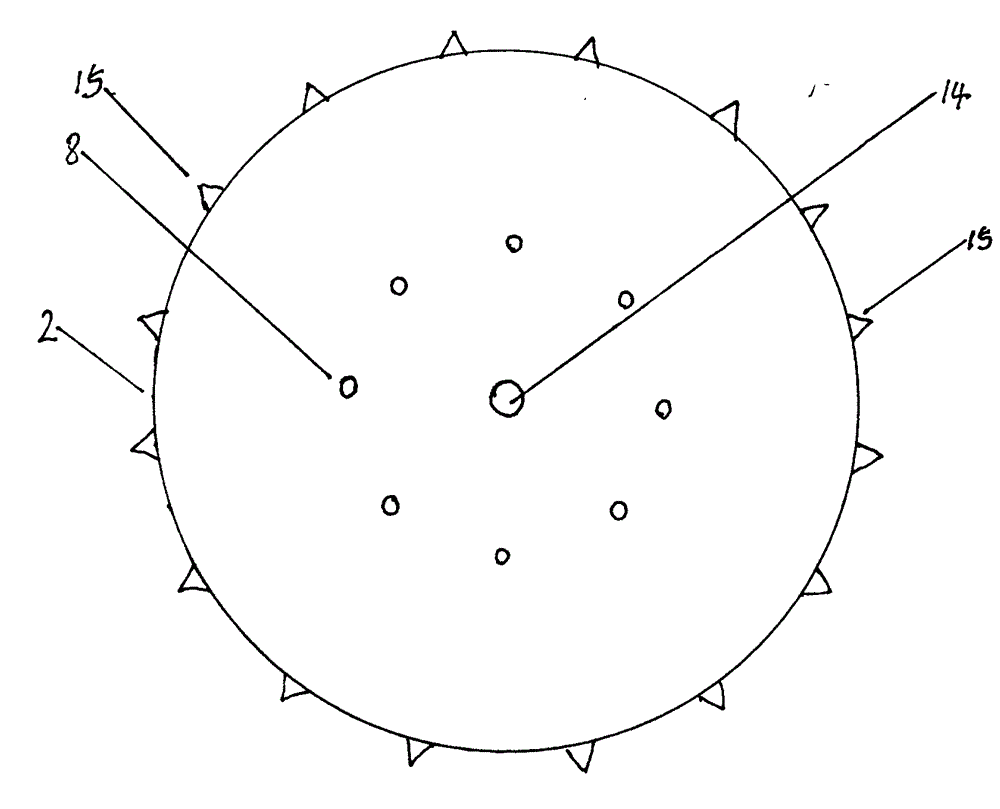

[0020] figure 2 It is the structural principle diagram of the seeding turntable. The circumference of the entire circular seeding turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com