Full-hydraulic rotary cultivator with triangular track wheel-type chassis

A triangular crawler and rotary tiller technology, which is applied in the field of agricultural operation machinery and rotary tiller, can solve the problems of not being able to adapt to complex terrain, inconvenient turning, and insufficient power of the rotary tiller, so as to achieve convenient and flexible turning, avoid equipment damage, and improve mechanism simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

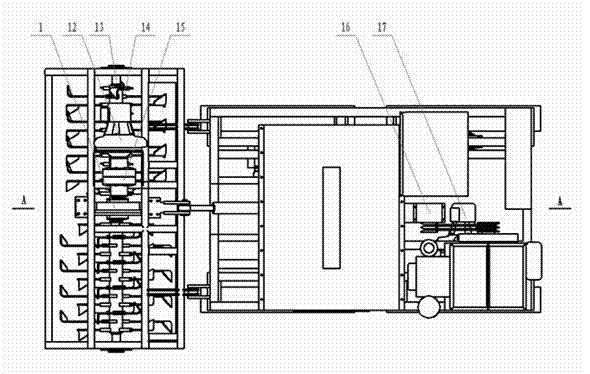

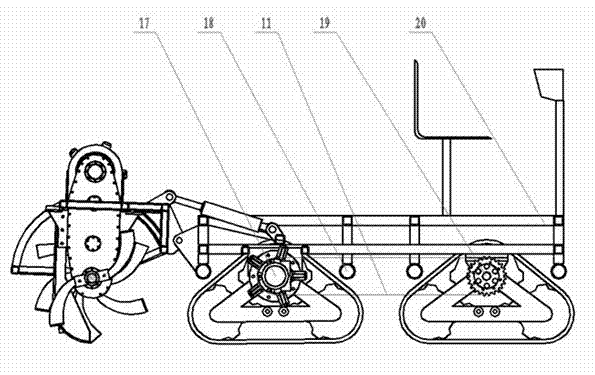

[0014] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the description of the embodiments. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. For Those of ordinary skill in the art can also obtain other drawings based on these drawings without making creative efforts.

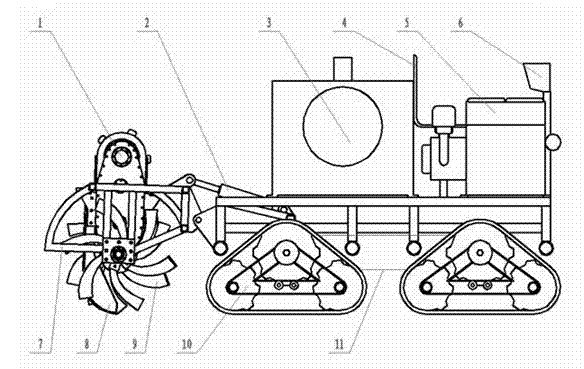

[0015] As shown in the accompanying drawings, a fully hydraulic triangular crawler wheel chassis rotary tiller includes a rotary tiller, a hydraulic chassis, a hydraulic system 3 and an operating console 6; the rotary tiller is suspended at the tail of the hydraulic chassis, and the rotary tiller includes a Gear box 1, rotary tillage hydraulic motor 12, coupling 15, rotary tiller shaft 13, rotary tiller disc 14, rotary tiller 9, coulter 8 and hydraulic cylinder 2 on the bracket 7, the gearbox 1 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com