Flexible direct current transmission converter valve steady-state high-power running testing device and testing method

A flexible DC transmission and operation test technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problem of difficulty in constructing full-load circuit tests, etc., and achieve the effect of flexible operation and simple control method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] Device embodiment of the present invention:

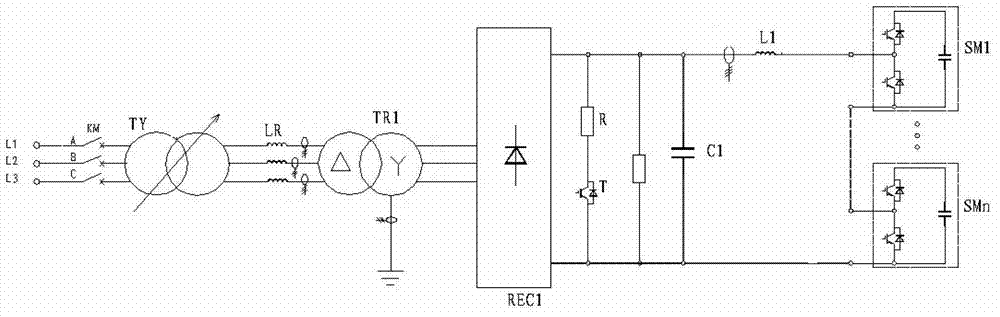

[0027] Such as figure 1 , the test device of the present invention includes an input circuit breaker switch KM, a three-phase voltage regulator TY, a filter reactor LR, an isolation transformer TR, a rectifier bridge REC1, a BUCK-BOOST buck-boost circuit, and a converter valve group. The group consists of n+k converter valve sub-modules SM1~SM(n+k) connected in series, including k redundant sub-modules, the number of sub-modules actually put into operation is n, and the converter valve group is connected in parallel The DC output terminal of the rectifier bridge, the BUCK-BOOST buck-boost circuit includes an IGBT module T, a resistor R1 connected in series with the IGBT module T, a DC bus support capacitor C1 and a load reactor L1, and the DC bus support capacitor C1 is connected in parallel to the IGBT mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com