Casing online bulge monitoring device

A technology of monitoring device and detection device, applied in the direction of measuring device, instrument, fiber mechanical structure, etc., can solve the problems of difficult confirmation, rapid water flow, broken Huff mold, etc., and achieves simple, safe and reliable operation, convenient and reliable operation, Ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

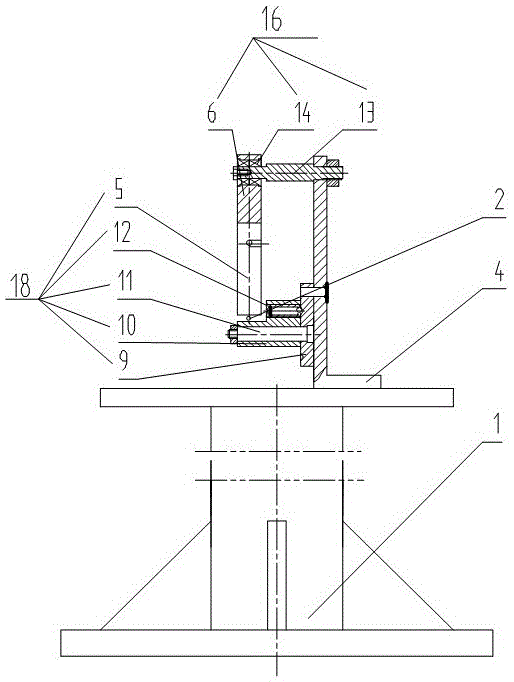

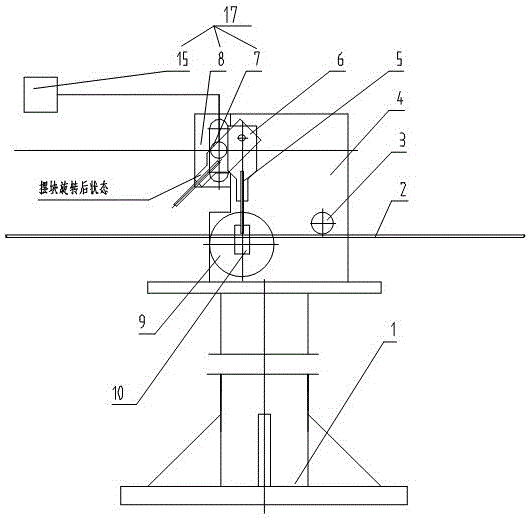

[0039] see Figure 1~2 , casing online bulge monitoring device, including a bracket 1, a fixed plate 4 is installed on the bracket 1, a pendulum device 16, a detection device 17 and a distance adjustment device 18 are installed on the fixed plate 4.

[0040] Described distance adjustment device 18 comprises adjusting block seat 9, and adjusting block seat 9 is installed on the fixed plate 4, and adjusting block seat 9 is equipped with adjusting block 10 by adjusting block shaft 11, and the central hole on the adjusting block 10 is eccentric, Therefore, the distance from the center hole to the edge of the adjustment block 10 is not equal. By rotating the adjustment block 10 around the adjustment block shaft 11, the distance between the adjustment block 10 and the bulge test piece 5 is changed. After the adjustment block 10 is rotated to a certain position, the built-in positioning screw 12 The inner marble is positioned in the pit of the adjustment block seat 9.

[0041] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com