Purified flue gas treatment device for domestic waste incineration plant

A technology for domestic waste incineration and flue gas treatment, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as waste of energy and environmental pollution, and achieve the goal of reducing energy loss, increasing incineration calorific value, and increasing incineration calorific value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

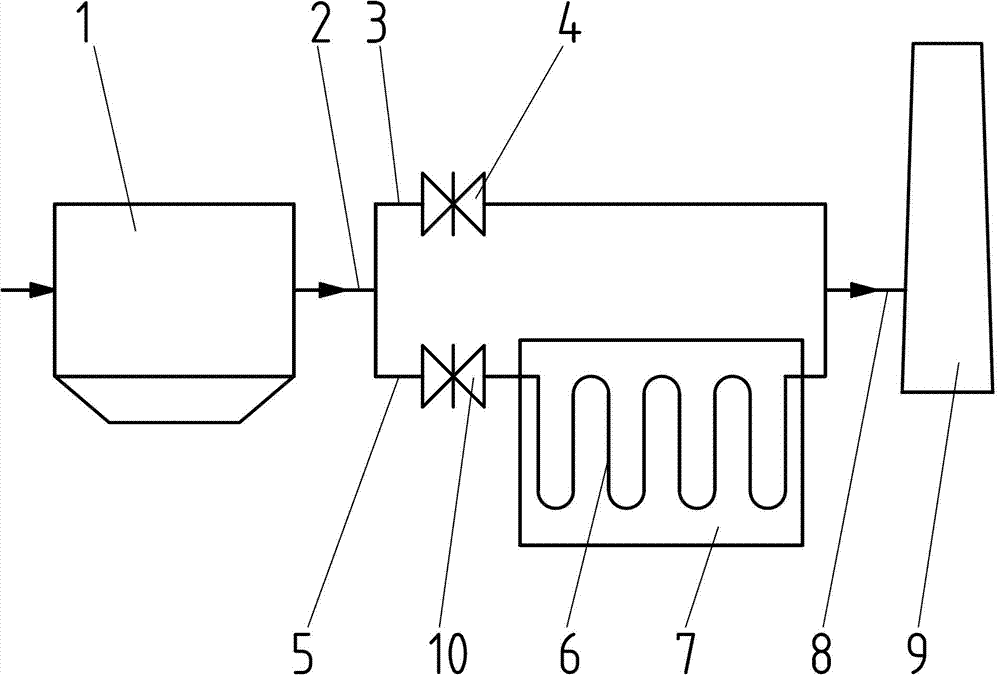

[0016] The present invention will be further described below in conjunction with the accompanying drawings. like figure 1 As shown, a device for treating flue gas after purification in a domestic waste incineration plant includes a dust collector 1, a main pipeline A2, a branch circuit A3, an electric gate valve A4, an electric gate valve B10, a branch circuit B5, a cooling device 6, a garbage storage pit 7, The main pipeline B8 and the chimney 9, the dust collector 1 is connected to the branch A3 and the branch B5 respectively through the main pipeline A2; the electric gate valve A4 is installed on the branch A3, and is connected to the chimney 9 through the main pipeline B8 ; The electric gate valve B10 is installed on the branch B5, and is connected to the chimney 9 through the cooling device 6 and the main pipe B8; the cooling device 6 is installed in the garbage storage pit 7. The dust collector 1 is a bag dust collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com