Reducing overlap joint combined type orifice pipe grouting method

A combined, orifice tube technology, applied in the field of bedrock grouting, can solve the problems of repeated grouting, time-consuming, labor-consuming and material-consuming, and achieve the effects of good economy, good grouting quality, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

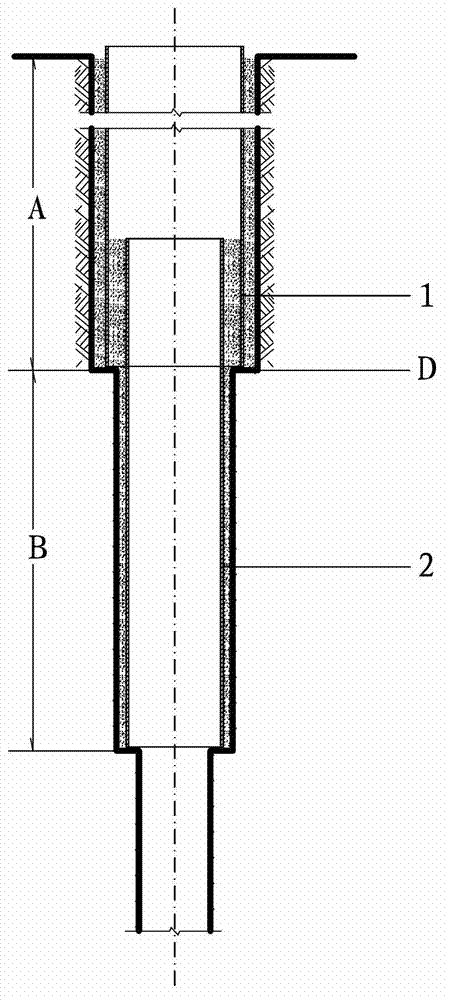

[0029] Such as figure 1 As shown, the variable-diameter lap joint combined orifice pipe grouting method, taking bedrock grouting under a deep overburden layer as an example, includes the following steps:

[0030] (1) When drilling a hole in the deep overburden layer A, combined with the mud wall solidification method, the fishtail drill is used to make the hole once drilled to the soil-rock contact surface D; Soil-rock contact surface D. The outer casing 1 is formed by connecting multiple sections of thick seamless steel tubes with flat joints and threads. Concentrated cement slurry is injected into the pipe wall of the outer casing 1, the outer wall of the pipe is turned into mud, and the thick seamless steel pipe is cast and fixed.

[0031] (2) Insert a drill bit with a smaller diameter into the outer casing 1, drill the bedrock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com