Natural and mild functional surfactant as well as preparation method and application of natural and mild functional surfactant

A surfactant and functional technology, applied in the field of functional surfactant and its preparation, can solve problems such as fertilizer loss and environmental pollution, and achieve the effects of wide application, huge economic benefits and special functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

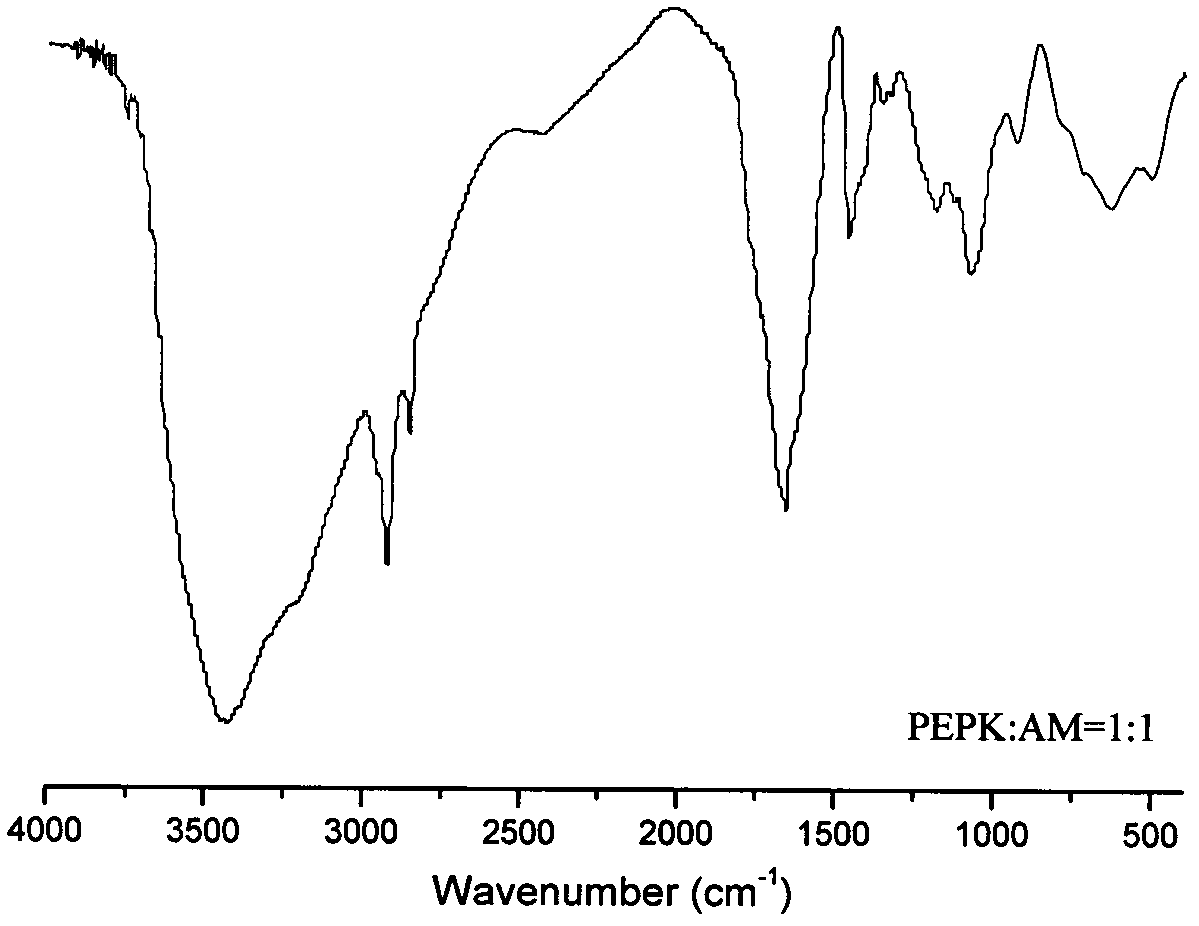

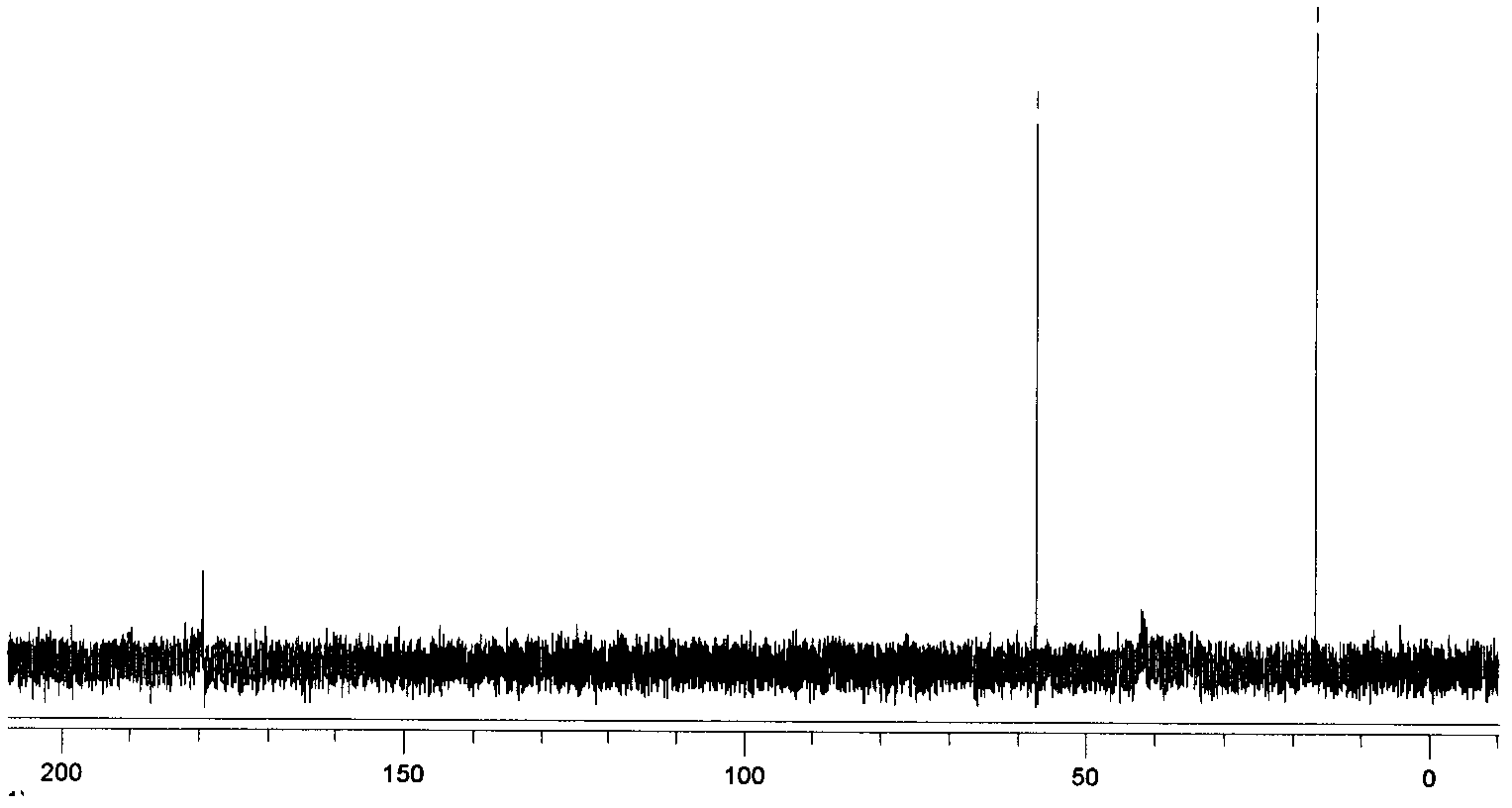

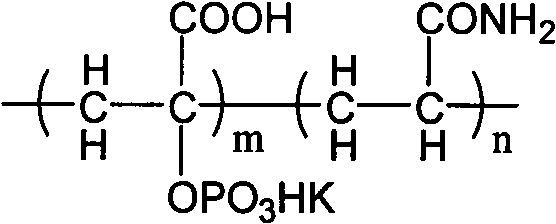

[0029] Please see attached Figure 1-2 , Preparation of PEPK-AM copolymer surfactant PM: Weigh 9g of acrylamide and pour it into an iodine flask filled with 100mL of ultrapure water, and stir evenly. Add 0.2g of sodium persulfate, 0.1g of sodium sulfite, and 9g of PEPK into the iodine flask in sequence, and stir evenly. Protect the reaction system with nitrogen gas and seal the bottle cap. After constant temperature stirring at 37°C for about 24 hours, a colorless viscous polymer solution was obtained. After adding about 100mL of absolute ethanol to the polymerization solution, a white sticky substance was precipitated. After filtering and shearing and drying, a porous white to light yellow block solid PEPK-AM copolymer was obtained, with a net weight of 16.75g (93% yield) . Take a small amount (10 mg) of the copolymer and add (1 L) deionized water and stir until the gel-like polymer is completely dissolved into a colorless and odorless clear liquid, which is the surfactant...

Embodiment 2

[0031] PM as LCD screen cleaner: Spray PM liquid directly on the surface of the LCD screen, the droplets are easy to adhere to the screen, and the dust and other stains can be removed by gently drying with a paper towel, and there is no trace of foam or other residues on the cleaned screen surface. To clean large oil stains on the surface of the screen, you need to use detergent to smear it first, and then use the above method to remove it. Compared with similar products from 3M, the cleaning power is equivalent, but the sprayed droplets tend to flow and are not easy to adhere to the screen, which is not as convenient as PM liquid.

Embodiment 3

[0033] PM as a rust and scale remover: Spray the PM solution on the rough surface of the sponge scouring pad, and then wipe it on the surface of stainless steel and copper products. Rust or scale stains on the surface of the product can be easily removed, which is much easier than scrubbing with decontamination powder; and the wiped surface looks bright and new, no need to clean again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com