Method for preparing vinyl carbonate by epoxy ethane and carbon dioxide

A technology of ethylene carbonate and ethylene oxide, which is used in the field of preparing ethylene carbonate from ethylene oxide and carbon dioxide, which can solve the problems of activity decline and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 0.06 g ZnCl 2 And 0.44 grams of TPPMS (monosulfotriphenylphosphine, structural formula (C 6 h 5 ) 2 PC 6 h 4 SO 3 H) add in 300 milliliter autoclave, then add 50.0 gram oxirane and 150.0 gram water (the weight ratio of catalyst and oxirane is 0.01, the weight ratio of water and oxirane is 3), charge into 1.0 MPa CO 2 , heated up to 120°C, and filled with CO 2 , maintaining the reaction pressure at 2.0 MPa, and after reacting for 3 hours, it was measured that the conversion rate of ethylene oxide was 48.9%, the selectivity of ethylene carbonate was 93.7%, and the yield of ethylene carbonate was 45.8%.

Embodiment 2~11

[0014] The types and amounts of transition metal salts and sulfonated phosphine ligands used were changed, and the remaining conditions were the same as in [Example 1]. The results obtained are shown in Table 1.

[0015] Among them, TPPDS is bis-sulfotriphenylphosphine, structural formula: C 6 h 5 P(C 6 h 4 SO 3 h) 2 ; TPPTS is three sulfotriphenylphosphine, structural formula: (C 6 h 4 SO 3 h) 3 P; BPTBP is bis(3-sodium phenylsulfonate)-4-tert-butylphenylphosphine, structural formula C 10 h 13 P(C 6 h 4 SO 3 Na) 2 ; PBTBP is 3-sodium phenylsulfonate-bis(4-tert-butylphenylphosphine), structural formula (C 10 h 13 ) 2 PC 6 h 4 SO 3 Na.

[0016] Table 1

[0017]

[0018] C EO %: conversion rate of ethylene oxide

[0019] S EC %: Selectivity of ethylene carbonate

[0020] x EC %: Yield of ethylene carbonate

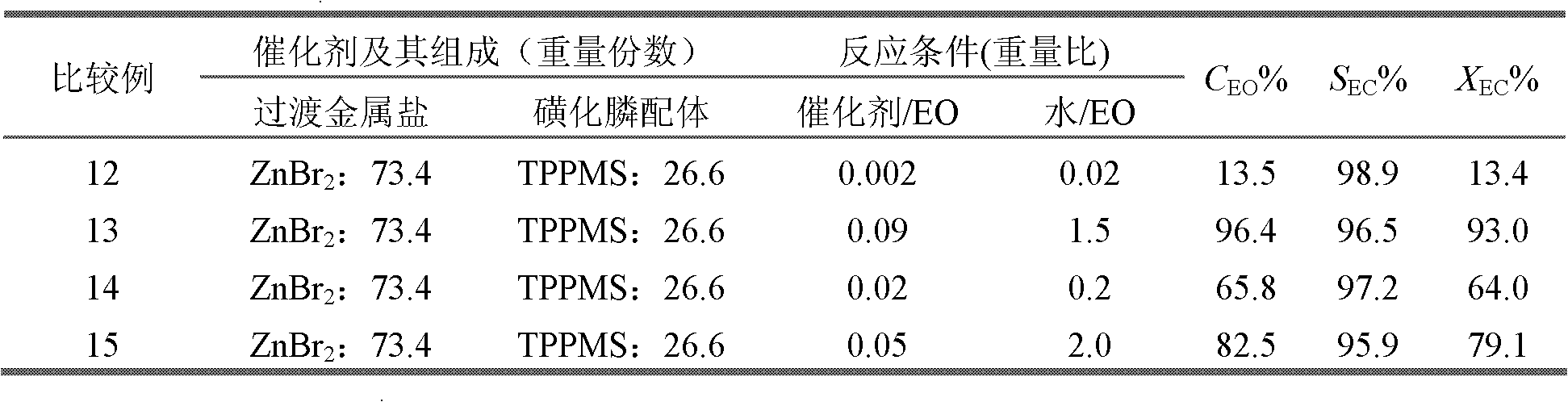

Embodiment 12~15

[0022] With [embodiment 4], just change the consumption of catalyst and the consumption of water, the obtained result is shown in Table 2.

[0023] Table 2

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com