Ammonium perchlorate

A technology of ammonium perchlorate and dosage, applied in the field of inorganic salts, can solve problems such as potential safety hazards, high friction sensitivity of formulations, and increased risk of composite solid propellants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

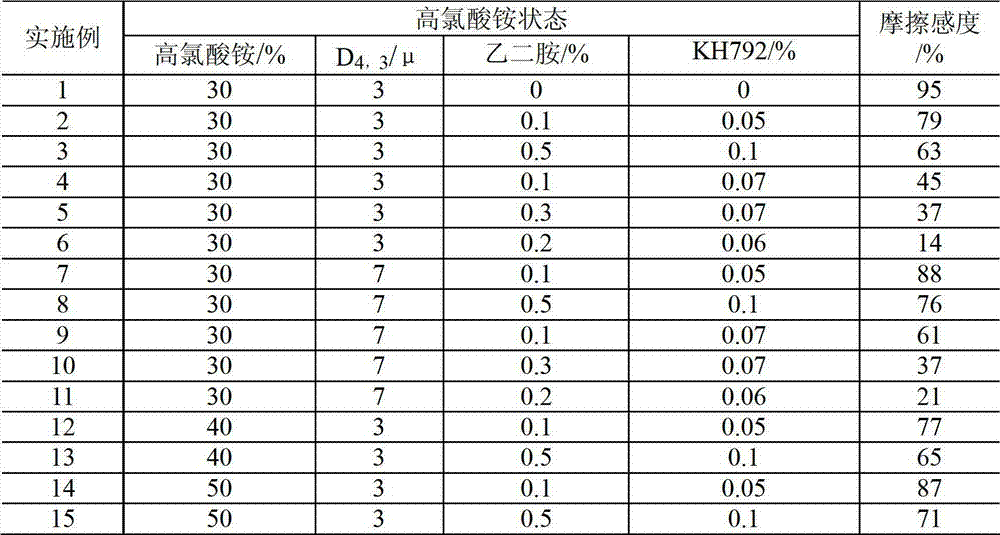

[0010] A certain composite solid propellant formulation contains 30% ammonium perchlorate, and the particle size of the ammonium perchlorate is D 4,3 It is 3μ, and the test results are shown in Table 1.

Embodiment 2

[0012] The ammonium perchlorate in a composite solid propellant formulation is 30%. The ammonium perchlorate is coated with ethylenediamine and KH792. The particle size of the ammonium perchlorate is D 4,3 It is 3μ, the ethylenediamine is 0.1%, the KH792 is 0.05%, the ethylenediamine is analytically pure, and the test results are shown in Table 1.

Embodiment 3

[0014] The ammonium perchlorate in a composite solid propellant formulation is 30%. The ammonium perchlorate is coated with ethylenediamine and KH792. The particle size of the ammonium perchlorate is D 4,3 It is 3μ, the ethylenediamine is 0.5%, the KH792 is 0.1%, the ethylenediamine is analytically pure, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com