Acid rain stone

An acid rain and zeolite technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of short supply of products, inconvenient use by farmers, large dosage, etc., and achieve the effect of shortening the improvement period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

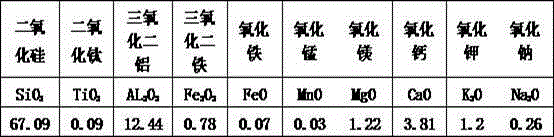

[0028] The acid rain stone of the present invention is prepared from the following components respectively (components by weight:

[0029] Component 1: Applicable to alkaline soil with pH value ≤10.0

[0030] Zeolite 30 kg + A product (zeolite + sulfuric acid) 65 kg + B product (zeolite + hymexazol, plant growth regulator) 5 kg.

[0031] Component 2: Suitable for salt nitrate

[0032] Zeolite 50 kg + A product (zeolite + sulfuric acid) 45 kg + B product (zeolite + hymexazol, plant growth regulator) 5 kg.

[0033] Acid rain stone preparation process of the present invention:

[0034] 1. Raw material selection: high-quality zeolite with a particle size of 10-20 mesh

[0035] Sulfuric acid 93% water solution

[0036] Hymexazol 30% water solution, plant growth regulator

[0037] 2. Process conditions:

[0038] The zeolite is made of high-quality zeolite, with a water content of 8%-10%, uniform particles and no impurities.

[0039] One group consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com