Moistureproof and leakproof feeding hopper for side feeding machine

A side feeding and hopper technology, which is applied in the field of feeding hoppers for side feeding machines, can solve the problems of material exposure, unqualified products, uneven material mixing, etc., and achieve the effect of preventing material leakage accidents and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

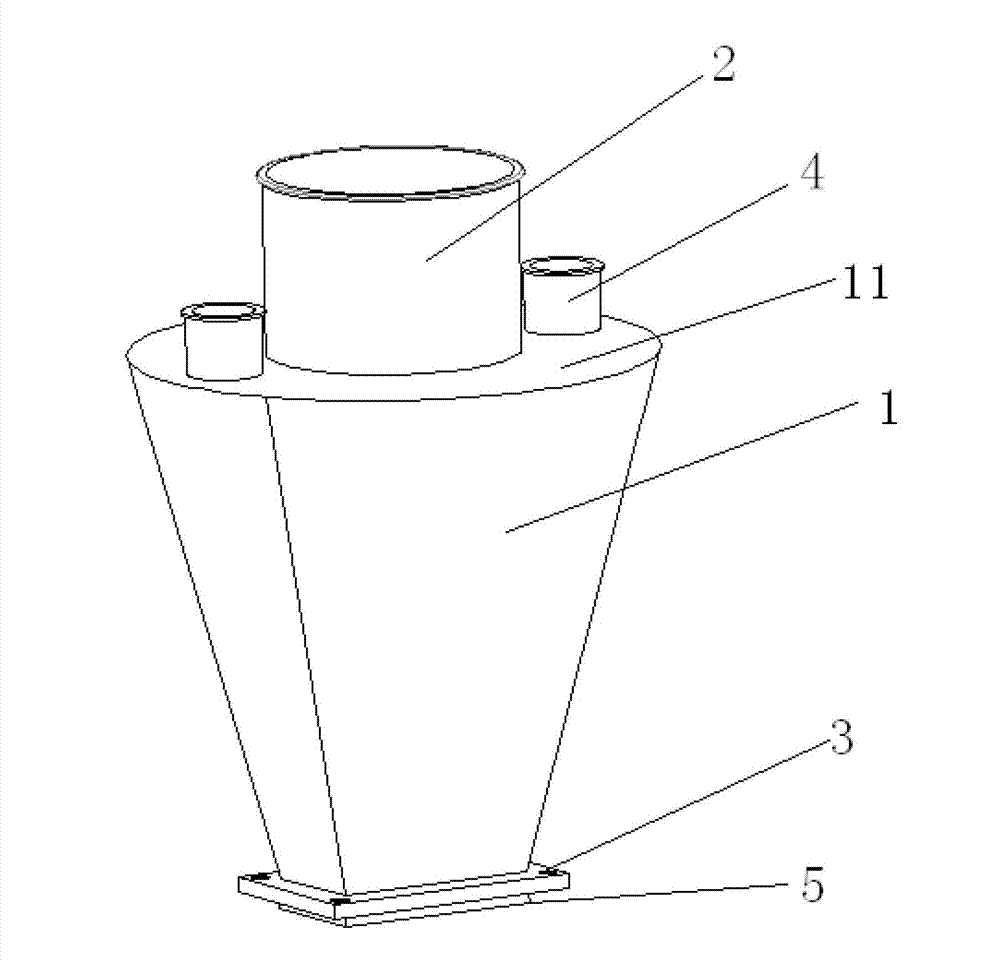

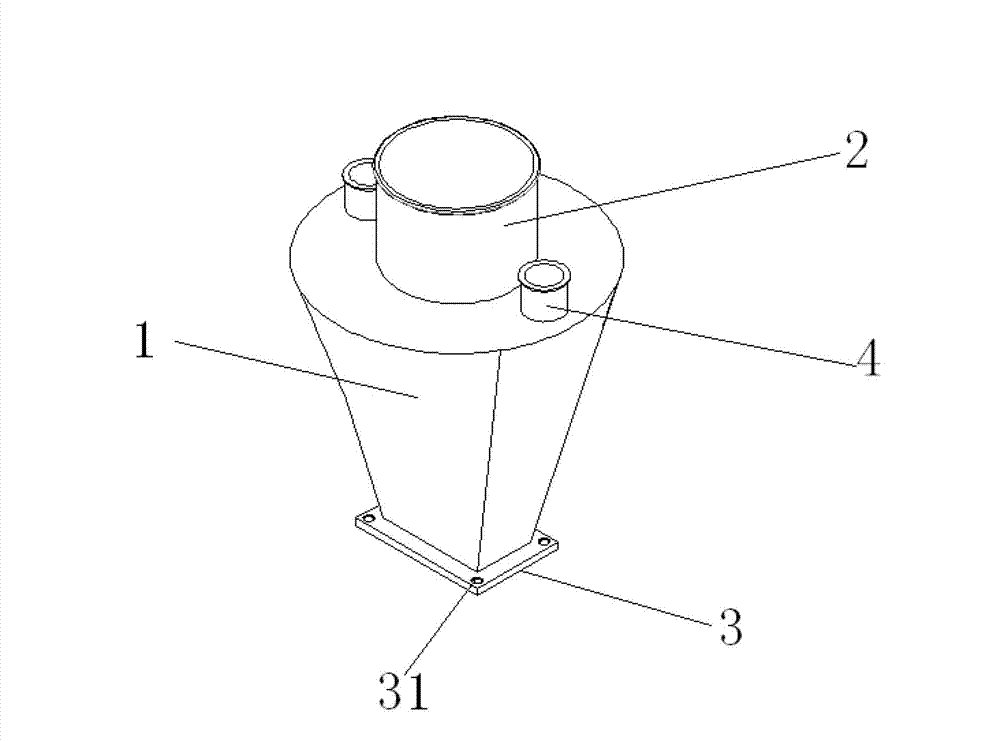

[0019] Such as figure 1 and figure 2 As shown, a moisture-proof and leak-proof feed hopper for a side feeder, based on the direction of use, includes a hopper body 1, a feed barrel 2 and a base 3, the upper end of the hopper body is in contact with the feed material The lower end of the cylinder is in sealing communication, the lower end of the hopper body is in sealing communication with the upper end of the base, the hopper body is provided with several ports 4 with functions of filtering, drying and exhausting, and the lower end of the base is provided with The annular bayonet 5 protruding from the lower end face of the base, like this, before using the feed hopper, the feed barrel is communicated with the large feeding hopper of the side feeder, and the annular bayonet provided on the base is pre-connected with the The feeding port of the side feeder matches, when the base with the ring-shaped bayonet is combined with the feeding port of the side feeder, the ring-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com