Section-type spray rod of manual sprayer

A sprayer and spray rod technology, applied in the field of agricultural appliances, can solve the problems of inability to achieve uniform control, small pesticide coverage area, poor efficiency, etc., and achieve the effects of simple structure, improved swing coverage area, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

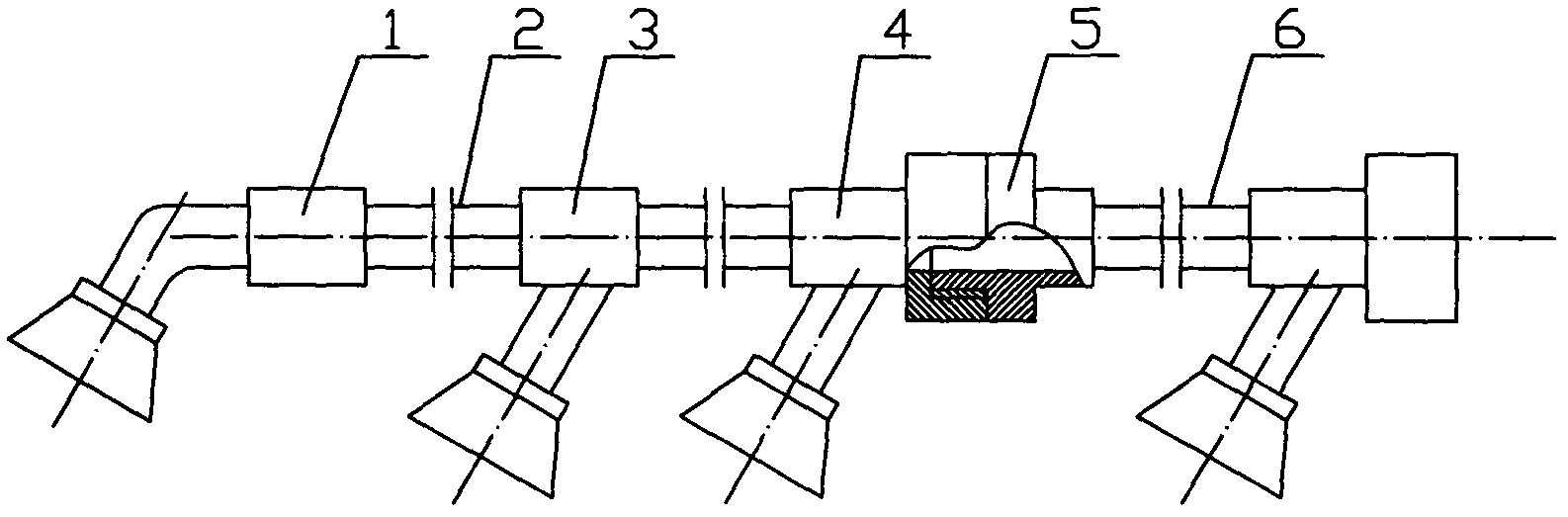

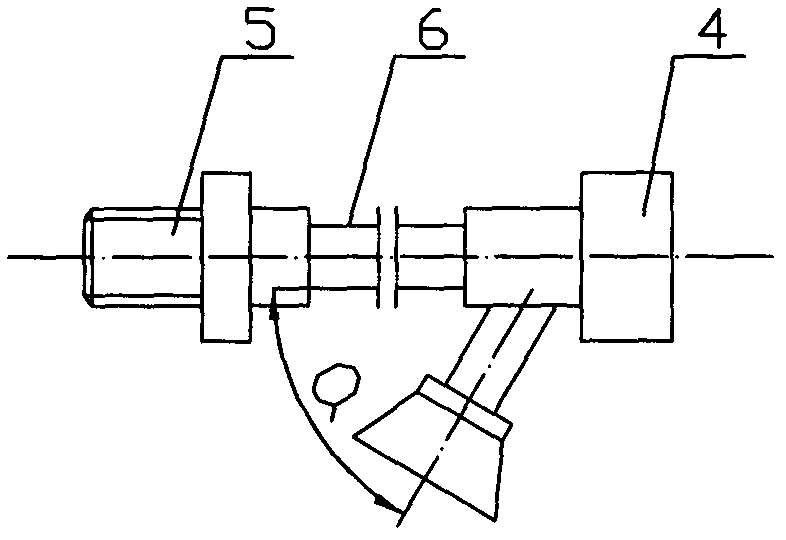

[0013] figure 1 The joint-connected spray rod of the manual sprayer shown is a two-section rod, which includes an outer nozzle 1, a main nozzle 2, a middle nozzle 3, an inner nozzle 4, a joint 5 and an auxiliary nozzle 6. The outer spray head 1 is a two-way structure, that is, the interface directly communicates with the downwardly inclined nozzle. The middle nozzle 3 and the inner nozzle 4 are of three-way structure, and the connections at both ends are straight-through pipes, and the straight-through pipe communicates with the downwardly inclined nozzle. The two main connecting pipes 2 are installed coaxially in series from two directions and are sealed to connect the middle nozzle 3 , the other ends of the two main connecting pipes 2 are respectively sealed and connected to the outer nozzle 1 and the inner nozzle 4 to form a main ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com