Improvements to the lubrication of the seats of a camshaft and a rocker-arm shaft in an internal combustion engine

A camshaft and rocker shaft technology, which is applied in the field of improving the lubrication of the camshaft base and rocker shaft base in internal combustion engines, can solve problems such as insufficient oil flow rate, and achieve good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

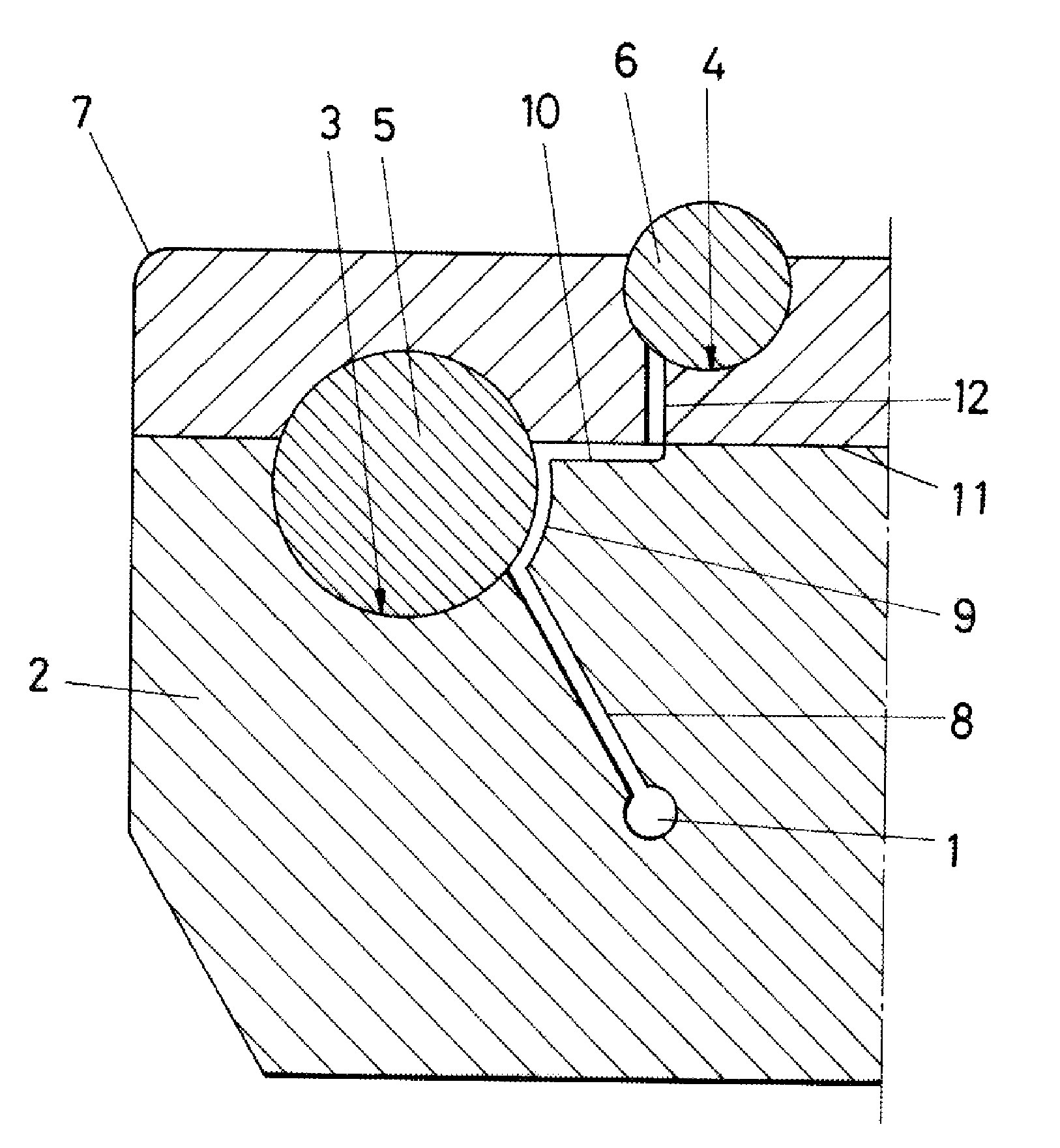

[0016] Considering the numbering adopted in the drawings, the improvement of the lubrication of the seats of the camshafts and the seats of the rocker shafts in internal combustion engines centers on the arrangement of some lines, some of which flow from deep transverse openings made in the cylinder head 2 1, and this line flows into the base 3 of some camshafts 5 and the base 4 of the rocker shaft 6, respectively.

[0017] The base 3 of the camshaft 5 is positioned in the cylinder head 2; while the base 4 of the rocker shaft 6 is positioned in the upper bracket 7 fixed to the cylinder head 2, and the upper bracket 7 is also held correspondingly to the base 3 of the camshaft 5 at the top of the camshaft 5.

[0018] The deep transverse bore 1 is part of the circuit of pressurized oil driven by a pump, and the pump rotates using the operation of the engine itself.

[0019] More specifically, an improvement is determined from the front ducts 8 , each of which extends from the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com