Planar horn antenna with impedance calibration function

A horn antenna, impedance calibration technology, applied in the direction of waveguide horn, circuit, etc., can solve the problems that affect the return loss and radiation performance of the antenna, can not improve the inconsistency between the horn antenna and free space wave impedance, and the horn antenna gain is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

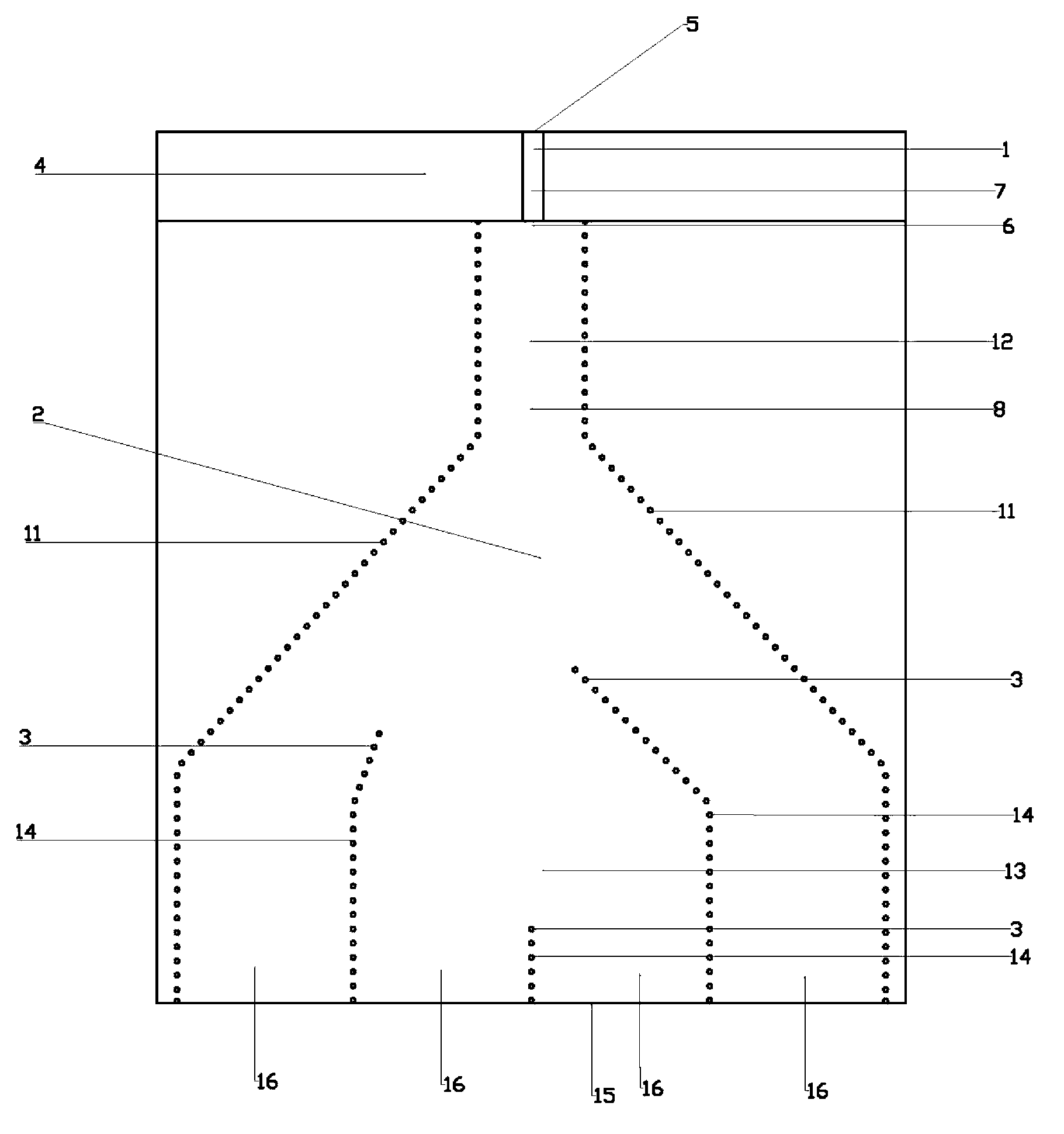

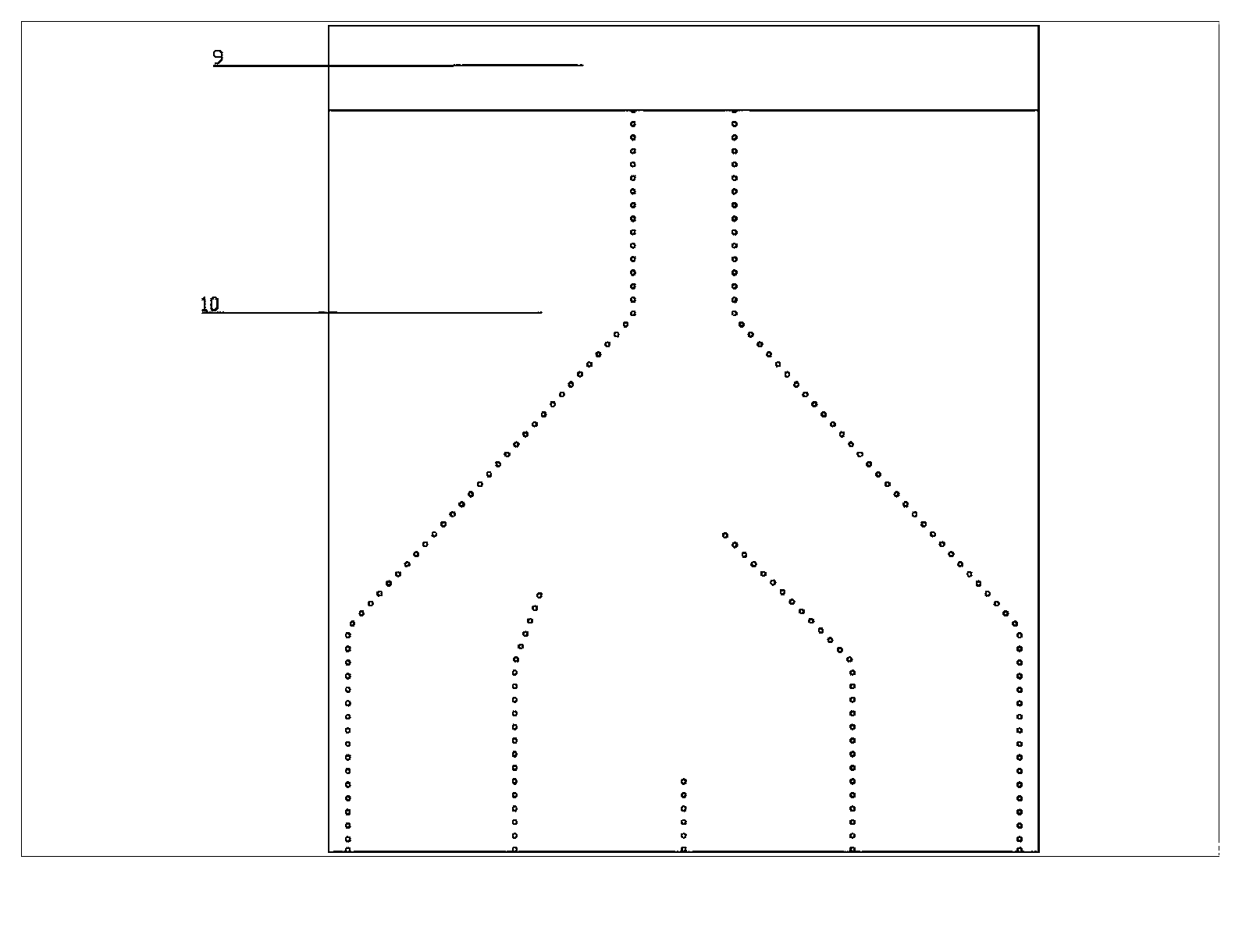

[0017] The embodiment adopted in the present invention is: the impedance-calibrated planar horn antenna includes a microstrip feeder 1, a substrate-integrated waveguide horn antenna 2 and an embedded metallized via hole 3, and these three parts are all integrated on the same dielectric substrate 4, One end of the microstrip feeder 1 is the input and output port 5 of the antenna, the other end of the microstrip feeder 1 is connected to the narrow port 6 of the substrate-integrated waveguide horn antenna 2, and the guide strip 7 of the microstrip feeder 1 is connected to the substrate-integrated waveguide horn The first metal plane 8 of the antenna is connected, and the ground plane 9 of the microstrip feeder 1 is connected to the second metal plane 10 of the substrate-integrated waveguide horn antenna; the substrate-integrated waveguide horn antenna 2 is composed of two m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com