Safety structure of a power battery pack

A technology of power battery pack and safety structure, which is applied to battery pack parts, structural parts, and secondary battery repair/maintenance, etc., can solve problems such as temperature rise of faulty batteries, explosion of faulty batteries, hidden dangers of normal operation of battery packs, etc. Achieve the effect of ensuring anti-vibration capability, protecting safety and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

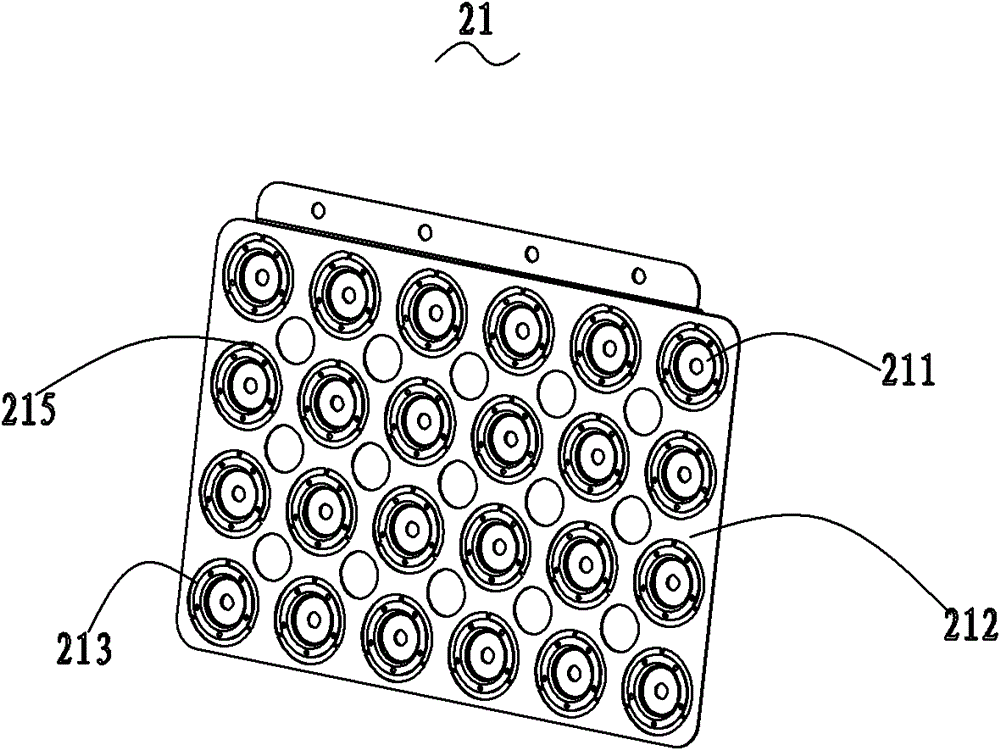

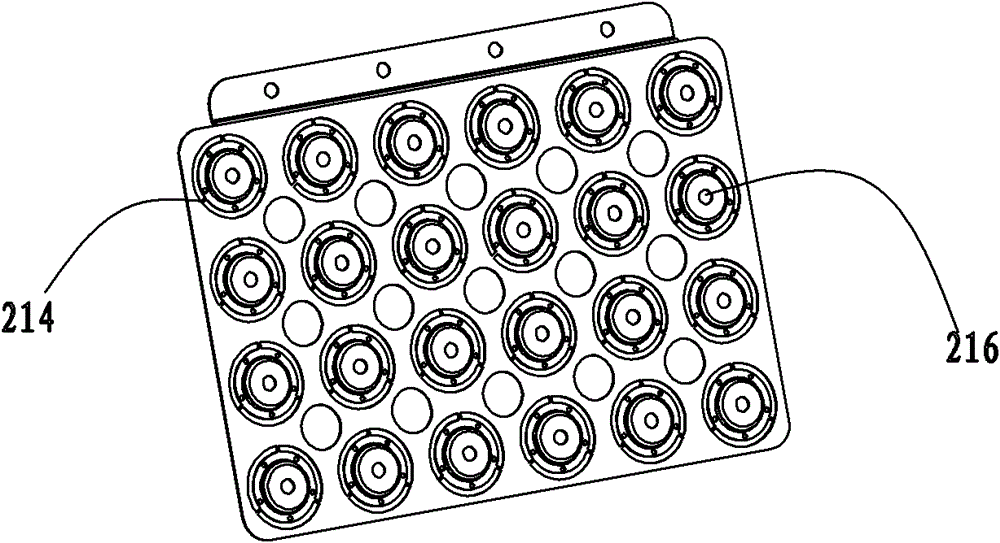

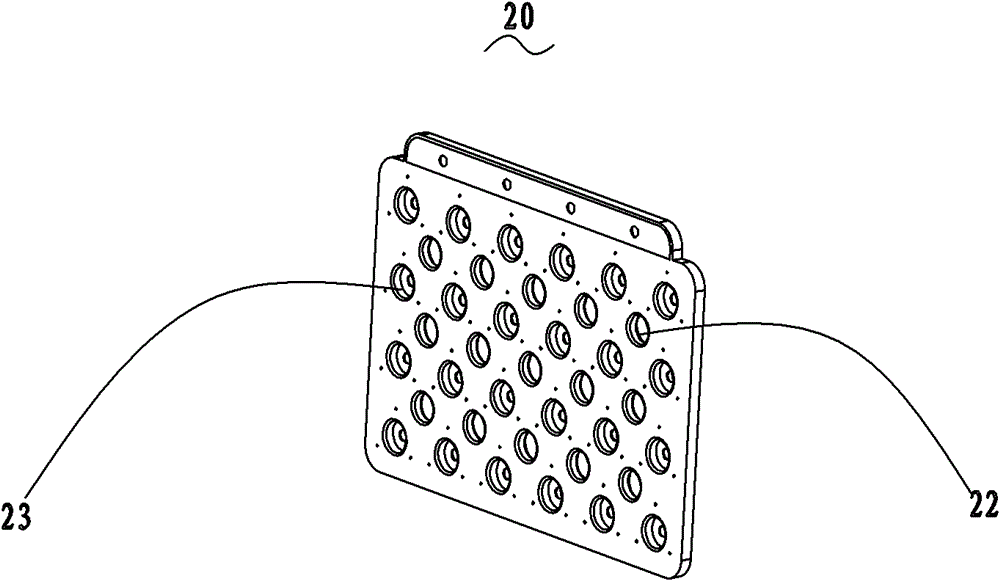

[0024] Please refer to Figure 1 to Figure 6 As shown, the safety structure of a power battery pack in the present invention, the battery pack 100 includes M sets of batteries, each set of batteries includes N×P single cells 10 arranged in a matrix and connected in parallel with each other, and the positive pole of each set of batteries is connected There is a reinforced circuit board 20, and a common pole plate 30 is connected to the negative pole, and each adjacent two groups of batteries are connected in series.

[0025] The reinforced circuit board 20 is roughly rectangular, and includes a conductive main board 21 and an insulating material (not labeled) covering the front and back of the conductive main board 21 and integrally formed with the conductive main board. Wherein, the conductive main board 21 includes N×P electrode connection pieces 211 and a base plate 212 for connecting the polarity of the single battery, an annular groove 213 is arranged between the electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com