Three-dimensional mechanical in-process model sequential modeling method based on removal feature recognition

A process model and feature recognition technology, applied in the field of machining, can solve problems such as low efficiency of process models and restrict the overall efficiency of 3D process design, and achieve the effect of ensuring rapid creation of requirements, reducing process preparation time, and simplifying difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Attached below Figure 1-19 The implementation steps of the present invention are described in detail.

[0065] Sequential modeling method of 3D machining process model based on feature removal recognition. This method first classifies and defines the feature removal; secondly identifies the feature removal based on the classification; finally completes the process model based on the result of feature removal recognition modeling. The specific technical route is as follows:

[0066] 1) Classification and definition of removal features

[0067] The removal features are divided into six categories, namely: boundary features, inset features, through features, thread features, ring features and other features.

[0068] (1) Boundary features

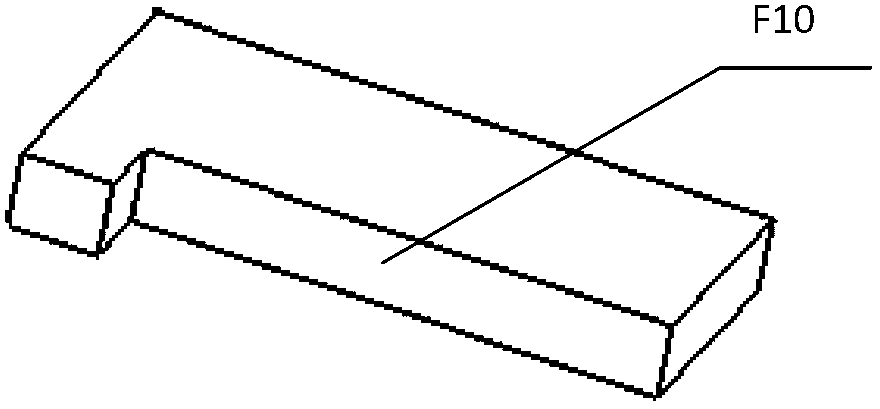

[0069] Refers to the shape on the boundary that is directly removed from the process model and intersects at least two or more blank surfaces, such as figure 1 Medium Feature F10.

[0070] (2) Inset features

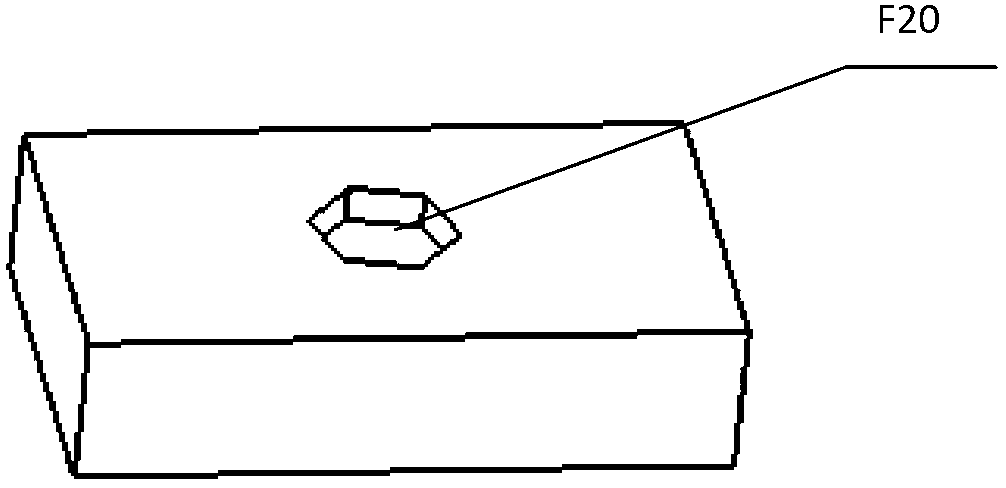

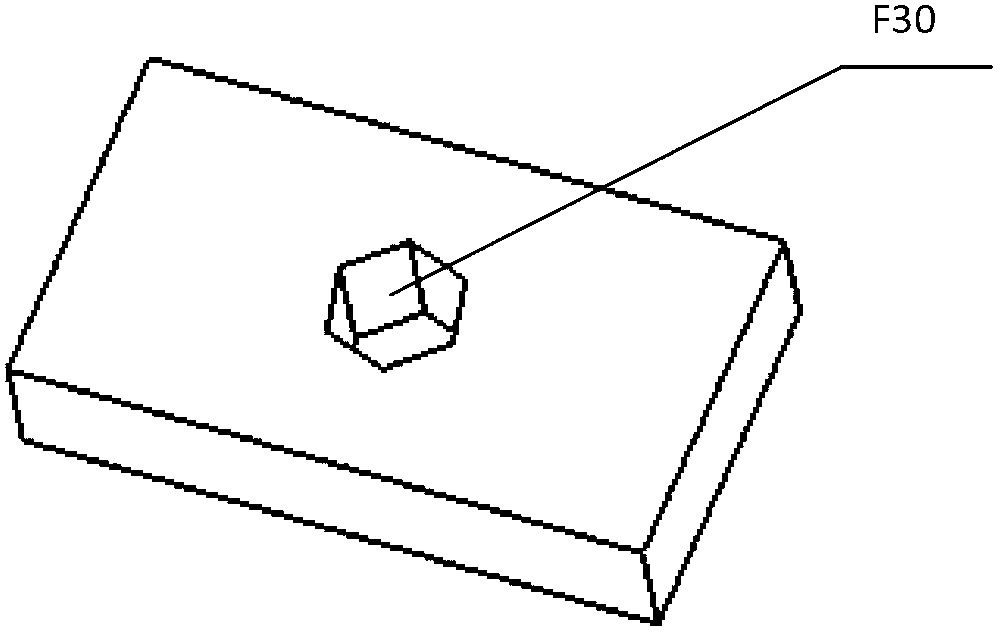

[0071] Refers to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com