Aluminum alloy multilayer composite plate bolt hole crack defect in-service electromagnetic detection device

An electromagnetic detection and composite board technology, applied in the direction of material magnetic variables, etc., can solve problems such as time-consuming detection and recovery, disassembly is not allowed, false alarms, etc., and achieve the effects of eliminating interference, avoiding missed detection, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

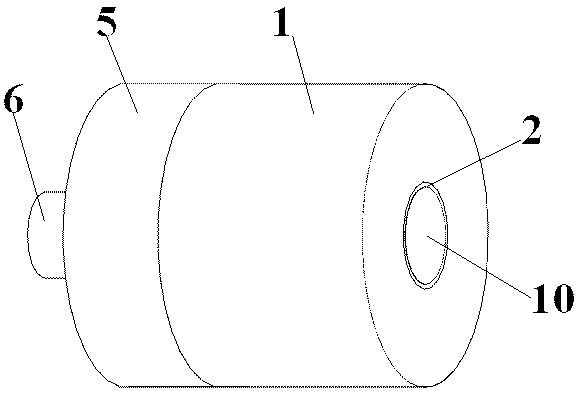

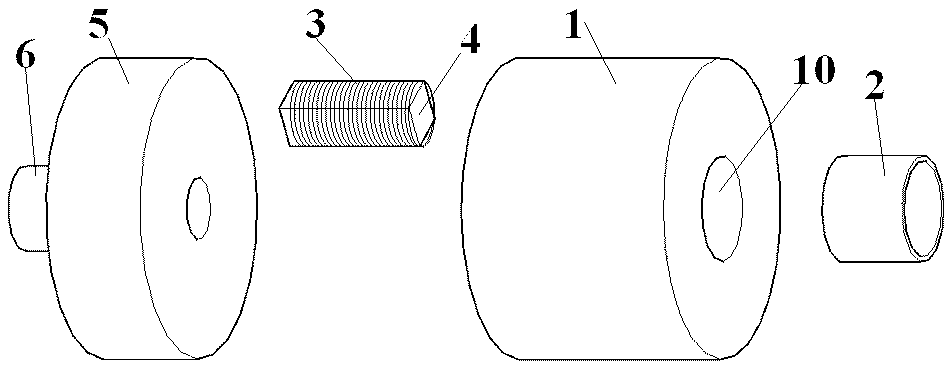

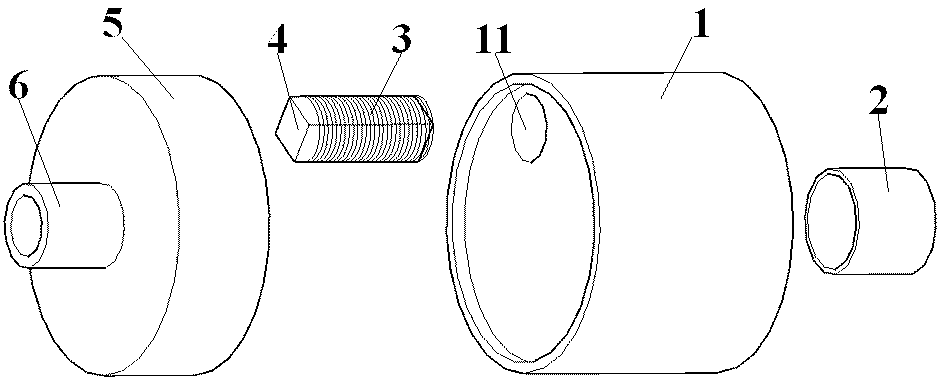

[0018] figure 1 , figure 2 , image 3 , Figure 4 In the first embodiment shown, the in-service electromagnetic detection device for bolt hole crack defects in aluminum alloy multilayer composite plates includes a sensor skeleton (1), a steel ring (2), a detection coil (3), a coil winding skeleton ( 4), sensor top cover (5), sensor output port (6). The steel ring (2) is embedded and fixed in the lower flat-bottomed hole (10) at the center of the bottom surface of the sensor frame (1); the detection coil (3) is evenly wound and fixed on the outer surface of the coil winding frame (4), and the detection coil (3) outputs The port is electrically connected to the sensor output interface (6); the detection coil (3) and the coil winding skeleton (4) are embedded into the upper flat-bottomed hole (11) on the upper surface of the sensor skeleton (1) off-center; the sensor top cover (5) is fixed on the upper surface of the sensor frame (1); the sensor output port (6) is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com