Backlight module

A backlight module and light source technology, applied in optics, light guides, light sources, etc., can solve the problem of increasing the distance required for light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

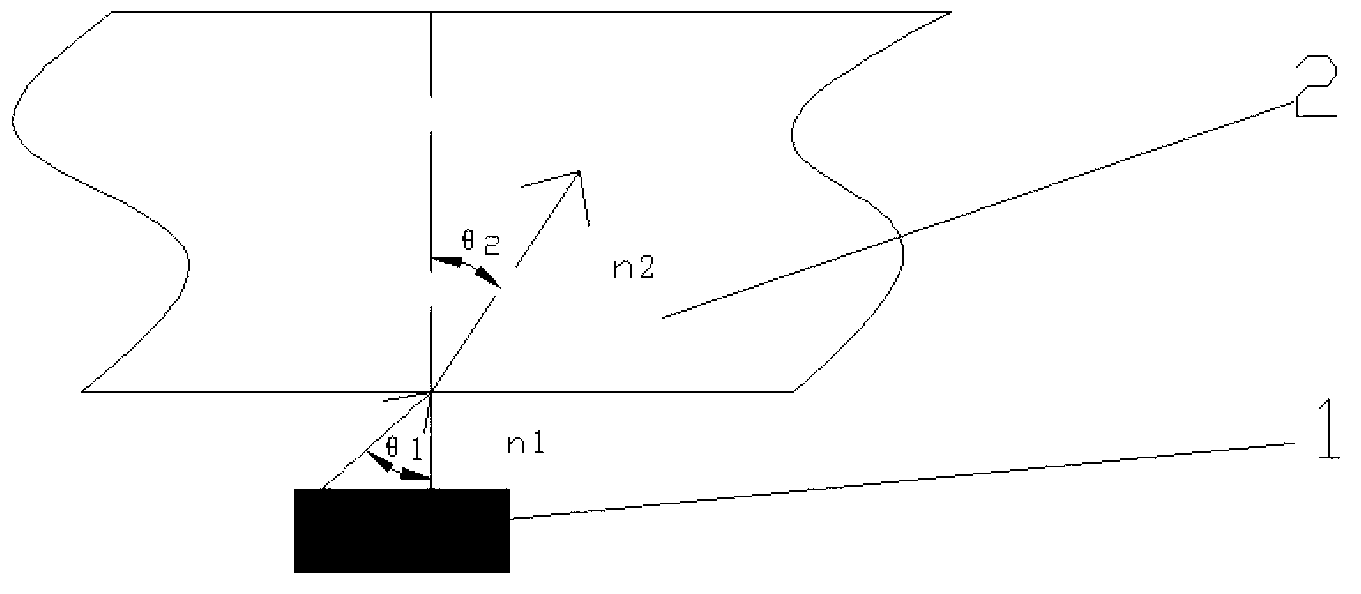

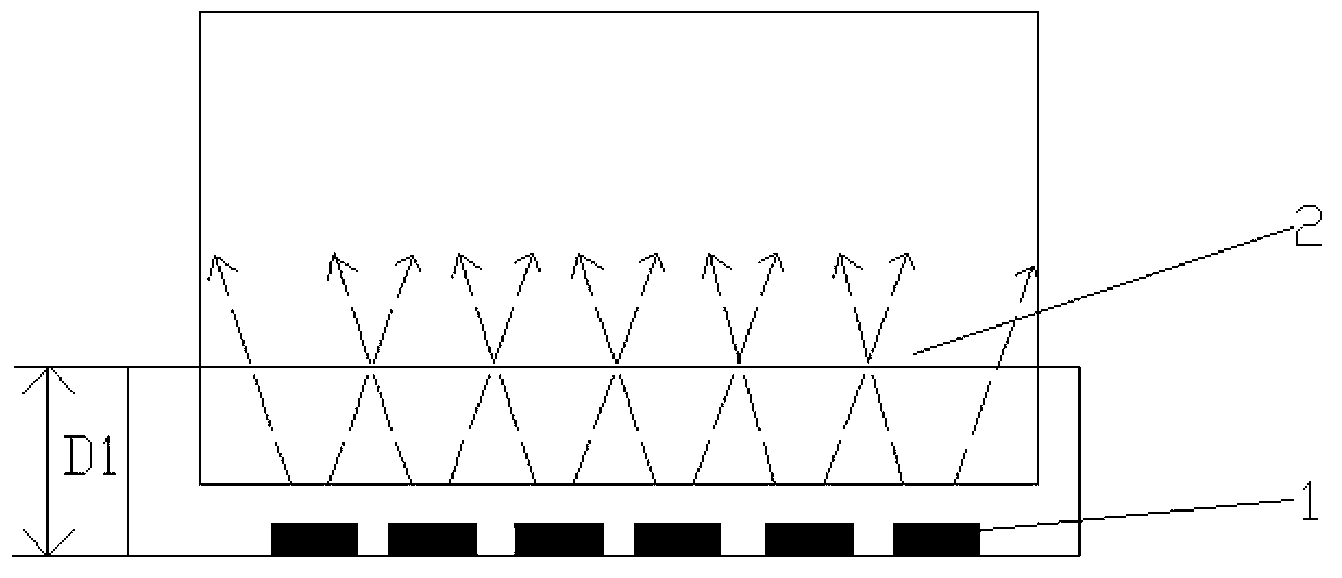

Method used

Image

Examples

Embodiment Construction

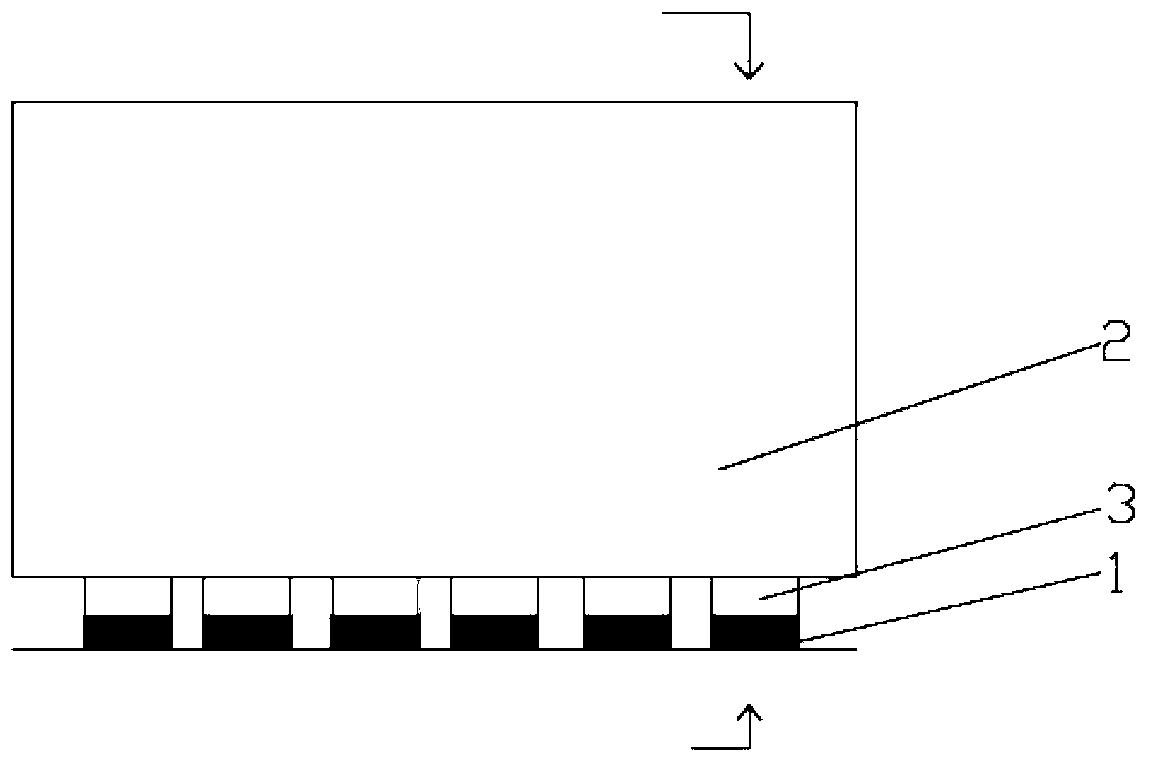

[0026] Such as image 3 , Figure 4 As shown, the backlight module of the present invention at least includes a light source 1, a light guide plate 2, and a light transmission structure 3. The light source 1 is composed of a plurality of LEDs, and the LED has a light emitting surface 11. The light guide plate 2 is made of transparent light guide Material molding, which includes a light incident surface 21 and a light exit surface 22 perpendicular to the light incident surface 21, the light transmission structure 3 is formed by a transparent light guide material, which includes a light incident surface 31 and a light incident surface 22 31 opposite to the light-emitting surface 32, which is arranged between the light-emitting surface 11 of the light source 1 and the light-receiving surface 21 of the light guide plate 2, and fills the gap between the light-emitting surface 11 of the light source 2 and the light-receiving surface 21 of the light guide plate 1, so The light emitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com