Method and system for temperature and humidity monitoring of high-energy pipeline subject to medium leakage in nuclear power plant

A technology for medium leakage and high-energy pipelines, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of brittle fracture of high-energy pipelines and high cost, and improve maintainability and accessibility , to ensure safety, to avoid the effect of double-ended breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

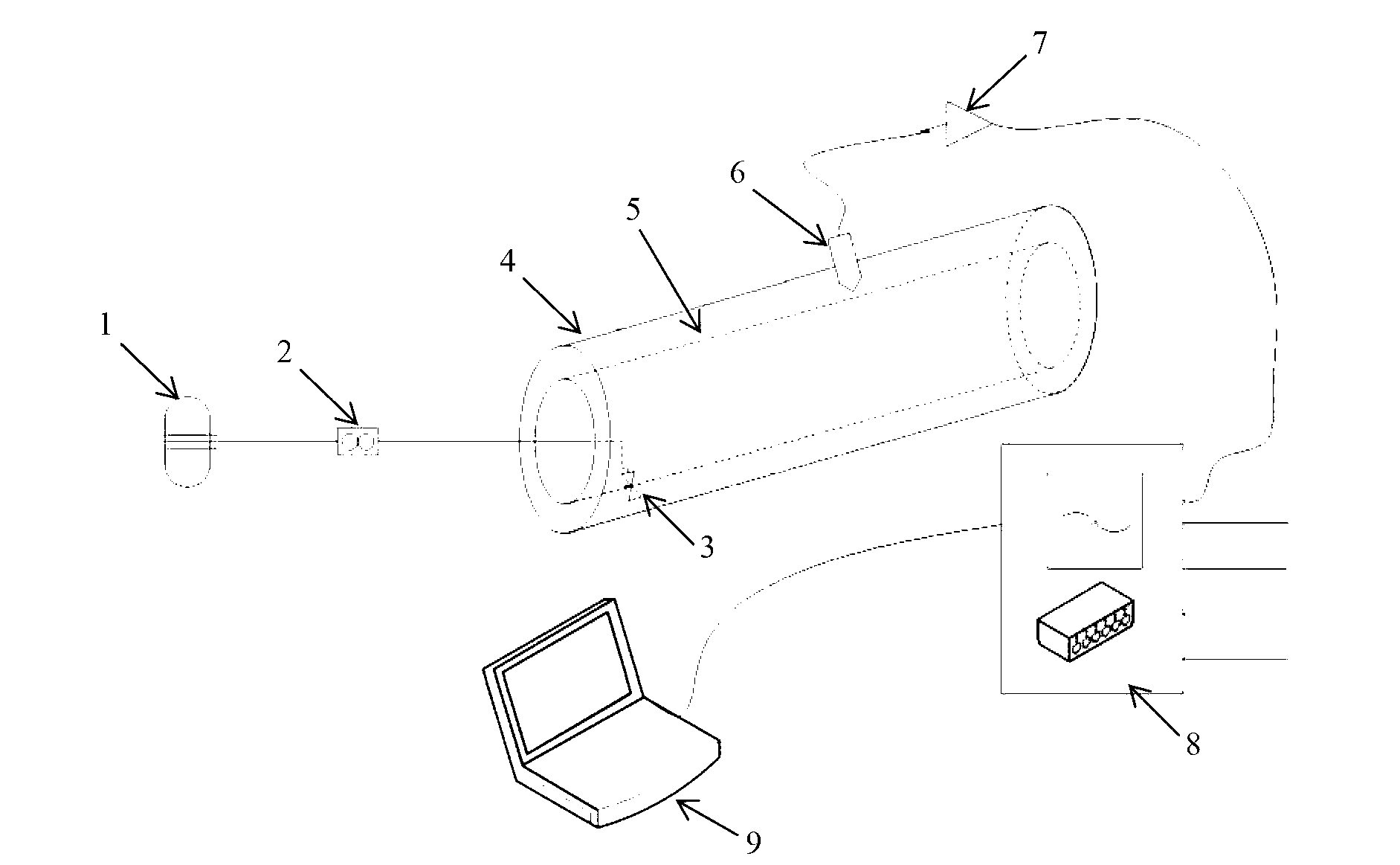

[0040] The invention uses temperature and humidity probes installed along the high-energy pipeline to locate the location of the leakage, evaluate the size of the leakage source, and monitor the leakage of the pipeline where the medium (water / steam) leaks.

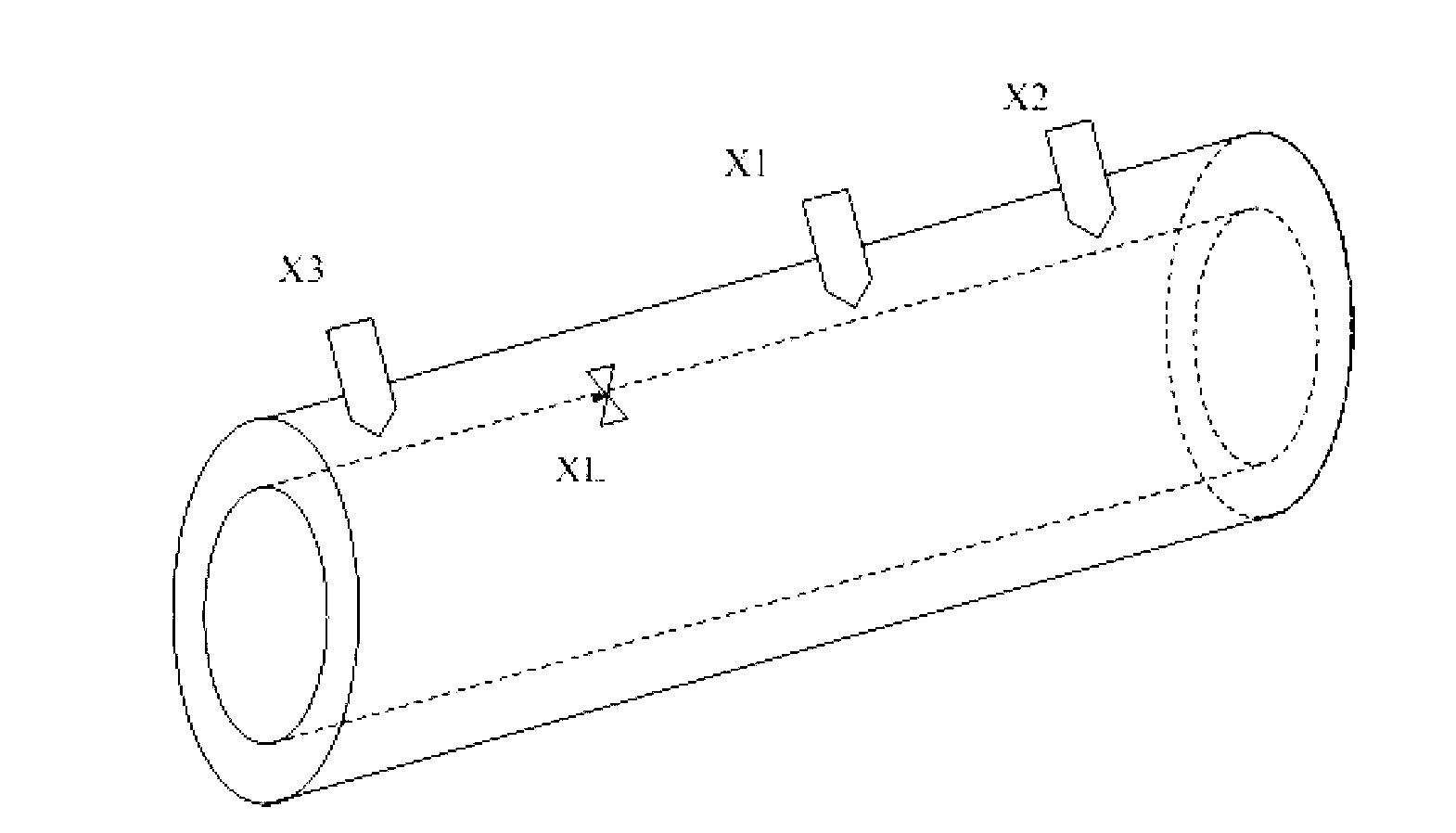

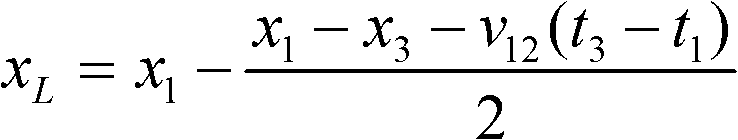

[0041] For high-energy pipelines with insulation layers, a fixed transmission channel is provided for the leakage medium between the insulation layer and the outer wall of the pipeline, and a temperature and humidity probe is installed on the transmission channel along the high-energy pipeline wall to measure the absolute humidity in the channel after the medium leaks Change (increase), and use the relative relationship of different times when different probes receive the humidity increase signal to identify the leak location. After the humidity probe records the humidity increase, the overall med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com