Intelligent hydraulic wellhead sealer

A wellhead sealer, hydraulic technology, applied in sealing/packing, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as air leakage, water leakage pollution, increase the load of pumping units, etc., and reduce environmental pollution , Easy to disassemble and install, prevent the partial wear of the polished rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

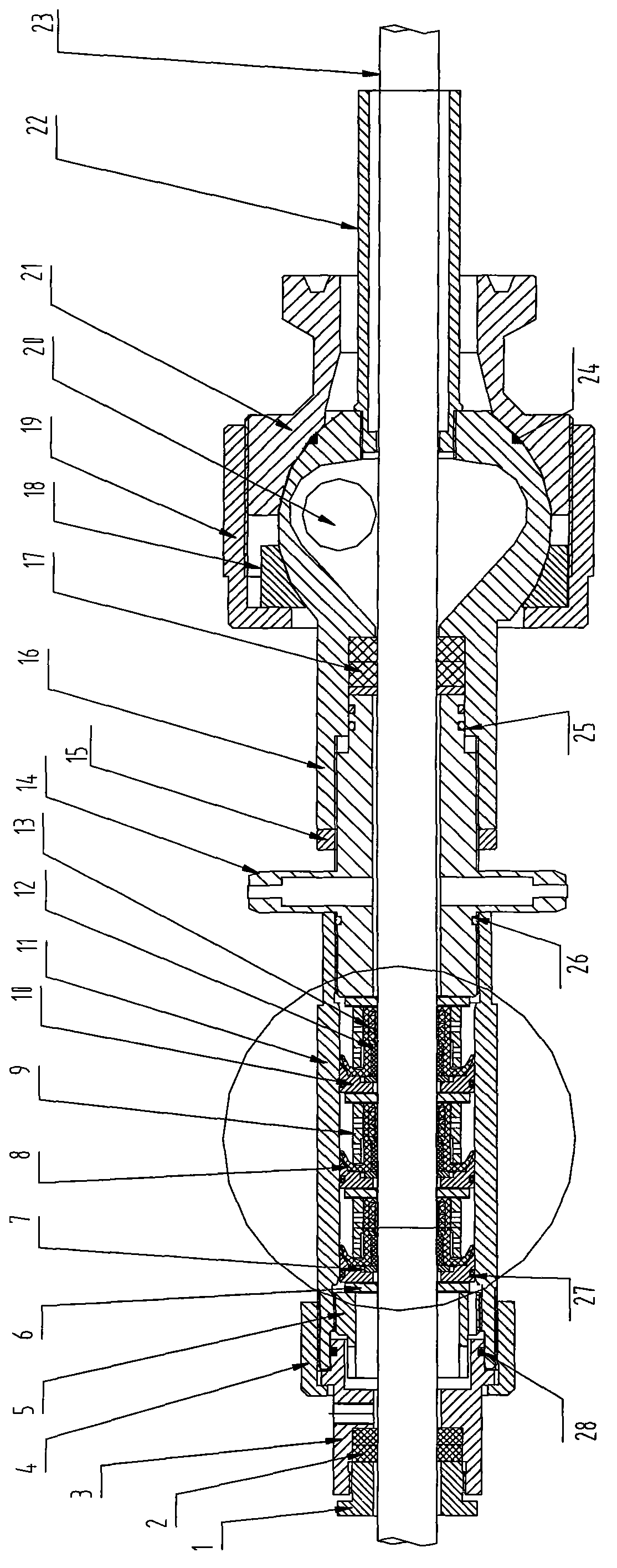

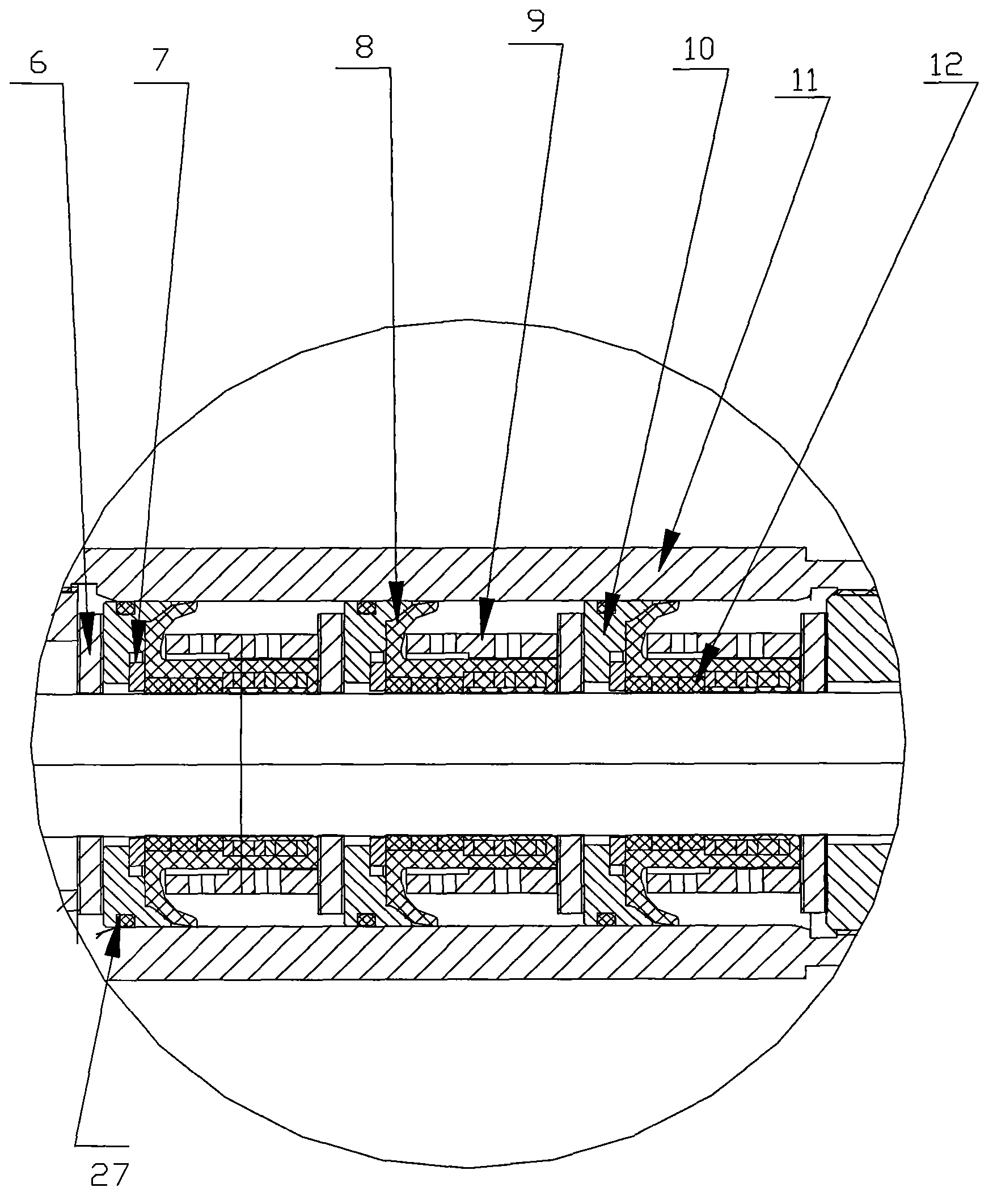

[0019] like figure 1 and figure 2 As shown, the present invention is an intelligent hydraulic wellhead sealer, which includes a polished rod 23. When in use, the product is installed on the wellhead of an oil well. The polished rod 23 runs through the intelligent hydraulic wellhead sealer longitudinally, and the polished rod 23 is connected to the rope suspension of the pumping unit. , so that the pumping unit and the pump are connected up and down to reciprocate. The middle part of the polished rod 23 is covered with a wax removal valve 14, and the front end of the wax removal valve 14 is threadedly connected with a jacket 11, and three sealing rings 12 are arranged in the cavity between the jacket 11 and the polished rod 23, and the sealing rings 12 are set on the polished rod 23; Made of metal, the gap between the polished rod 23 and the sealing ring 12 is 0.5mm. During operation, the polished rod 23 of the pumping unit goes down, and the upper part of the product sealing...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that two sealing rings 12 are arranged in the cavity of the casing 11 and the polished rod 23 .

Embodiment 3

[0025] The difference between this embodiment and Embodiment 1 is that four sealing rings 12 are arranged in the cavity of the jacket 11 and the polished rod 23 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com