A multi-functional adjustable buckle plate assembly

An adjustable and multi-functional technology, applied in the direction of housing structure support, housing structure support, scaffolding connection, etc., can solve problems such as poor variability and applicability, inability to meet construction requirements, size restrictions, etc., to achieve flexible scaffolding and installation. The effect of easy disassembly, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

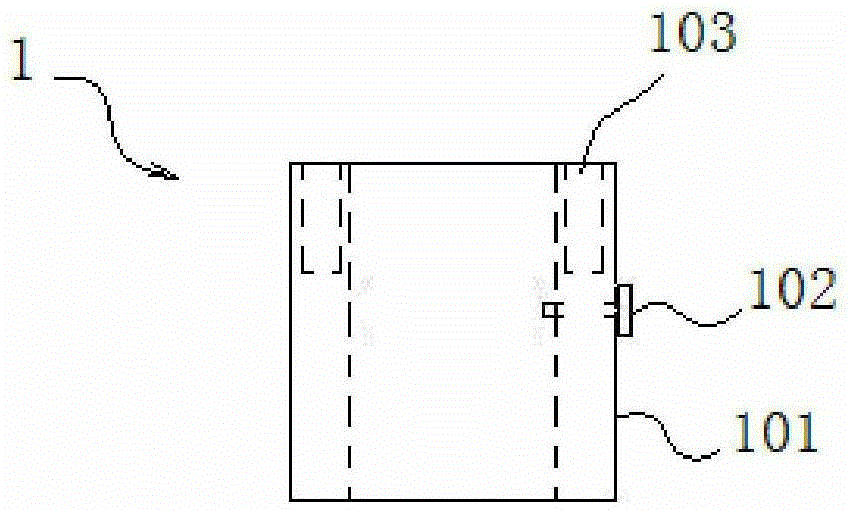

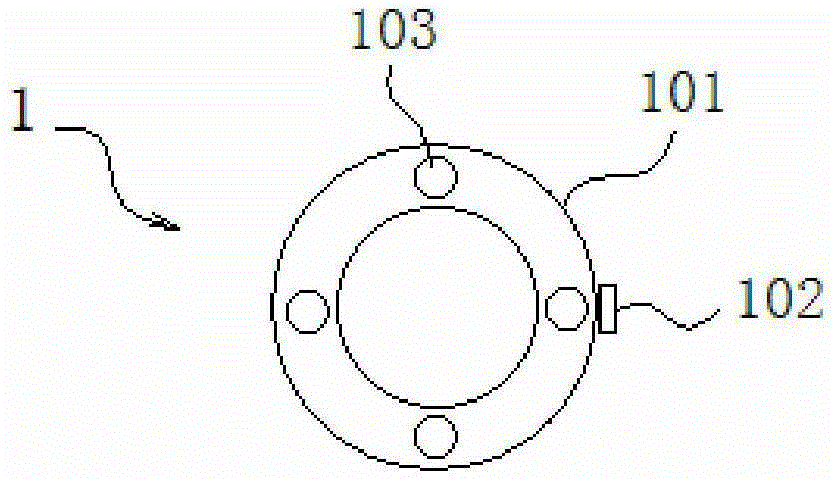

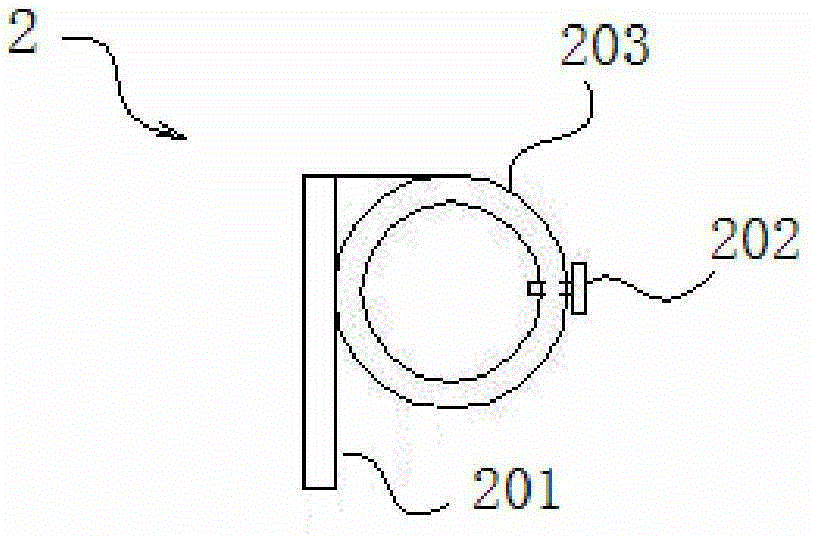

[0044] See figure 1 — Figure 4 , the multifunctional adjustable buckle plate assembly provided by the present invention includes a fastener 1 and a plug 2, the fastener 1 includes a vertical first sleeve 101, and the end of the first sleeve 101 is provided with a socket ( or slot) 103; the plug 2 includes an insertion rod 201 that cooperates with the jack (or slot) 103 on the first sleeve 1, and the insertion rod 201 is fixed with a horizontal second sleeve 203, the second Both the first sleeve 101 and the second sleeve 203 can be fixed on the vertical pipe and the horizontal pipe of the scaffold by fastening screws 102 and 202 .

Embodiment 2

[0046] See Figure 5 , Image 6 , this embodiment is based on Embodiment 1, the end of the first sleeve 101 is provided with an annular buckle 104, the jack (or slot) 103 is set on the buckle 104, and the buckle 104 is also provided with a socket 103' that cooperates with the oblique rod in the scaffold.

Embodiment 3

[0048] See Figure 7 — Figure 11 , this embodiment includes a fastener 1, a plug 2 and a safety buckle plate 3, the fastener 1 includes a vertical first sleeve 101, the end of the first sleeve 101 is provided with a slot 103, the first sleeve 101 is composed of left and right split parts 101', one side of the two parts 101' of the first sleeve is hinged by a hinge 105, and the other side is connected by a bolt 102; The slot 103 on the barrel 101 matches the insertion rod 201, the insertion rod 201 is fixed with a horizontal second sleeve 203, the side of the second sleeve 203 is connected with the insertion rod 201, and the insertion rod 201 is provided with a positioning pin 204 The insurance buckle plate 3 includes an annular body 301, and the annular body 301 is provided with a jack (or slot) 302 that cooperates with the positioning pin 204 on the insertion rod 201 of the plug 2 and a jack that cooperates with the inclined rod in the scaffold 303.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com