Automated production line for carpet flat seams

A technology for automated production lines and blankets, applied in sewing units, sewing equipment, sewing machine components, etc., can solve problems such as the lack of effective guarantee of product quality, uneven level of interlock sewing technology, and difficulty in overcoming the fillet interlock technology with rounded corners. , to avoid uneven product quality, improve production efficiency, and improve the quality of interlock seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

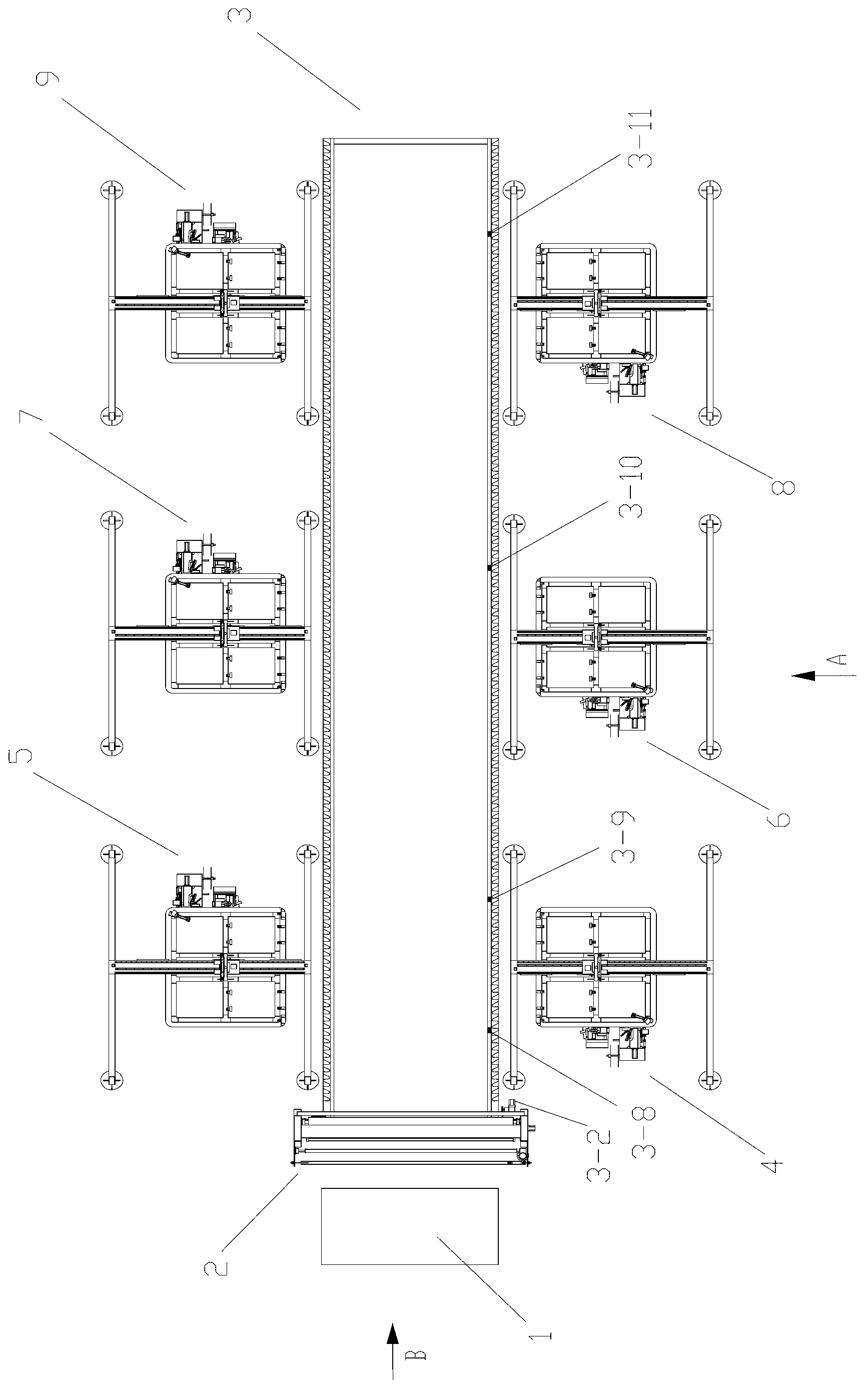

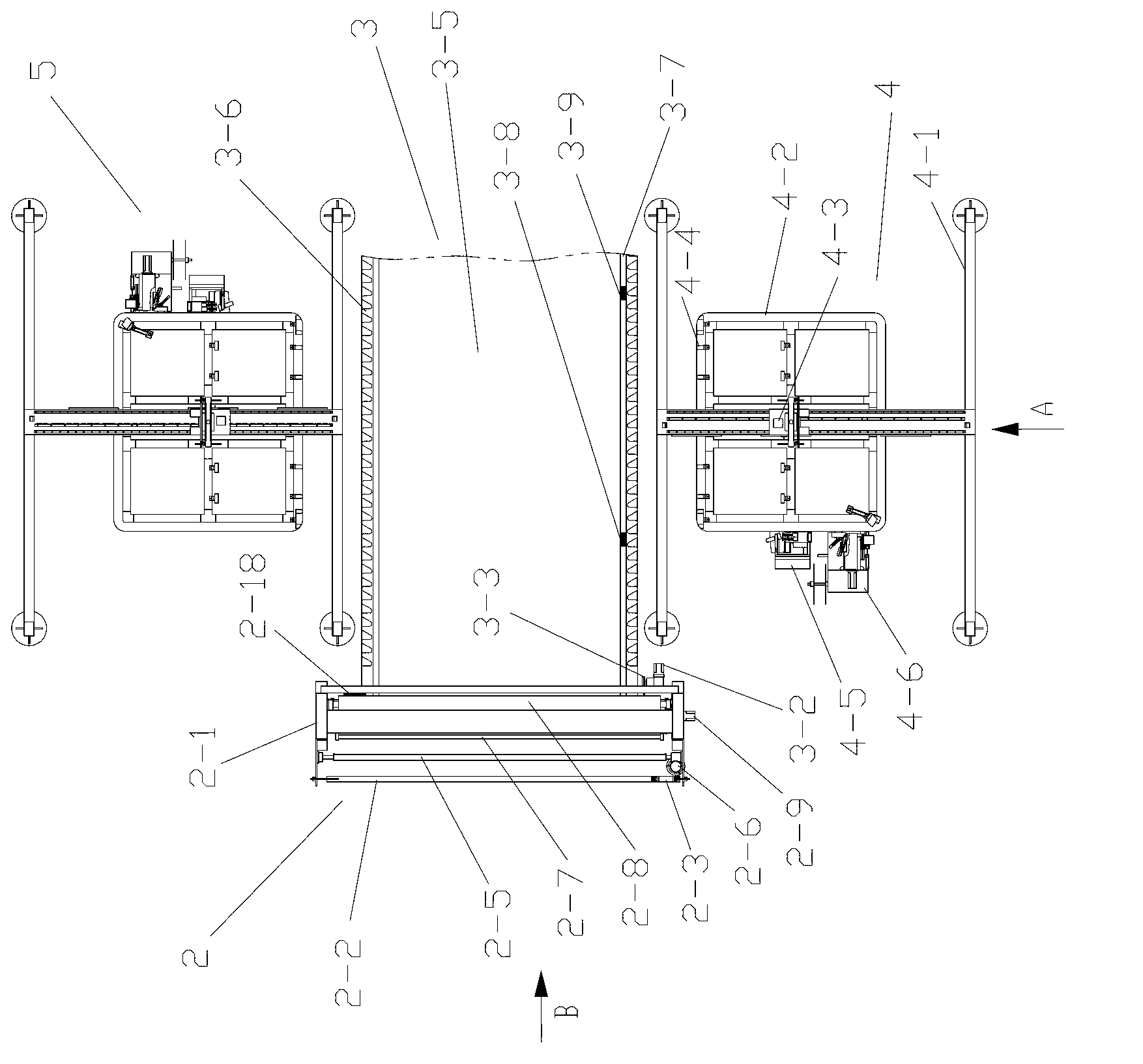

[0015] combine figure 1 , the automatic production line for blanket seaming of the present invention comprises a rolled blanket 1, a blanket feeding mechanism 2, a conveyor belt mechanism 3, and more than two automatic blanket seaming stations, and more than two blanket automatic seaming stations are respectively placed on both sides of the conveyor belt mechanism 3 , the rolled blanket 1 feeds into the blanket feeding mechanism 2, the blanket feeding mechanism 2 presses the blanket on the conveyor belt mechanism 3, and the conveyor belt mechanism 3 transmits the edge of the blanket to the first photoelectric sensor 3-8 and then the cutter blade 2- 18. Cut the blanket into strips. The first blanket cut into strips is sent to the edge of the second photoelectric sensor 3-9 through the conveyor belt mechanism 3. After that, the first blanket automatic flat seam station 4 grabs the blanket and performs flat seam. The conveyor belt mechanism 3 continues to run, and the second blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com