Preparation method of eggplant stalk activated carbon

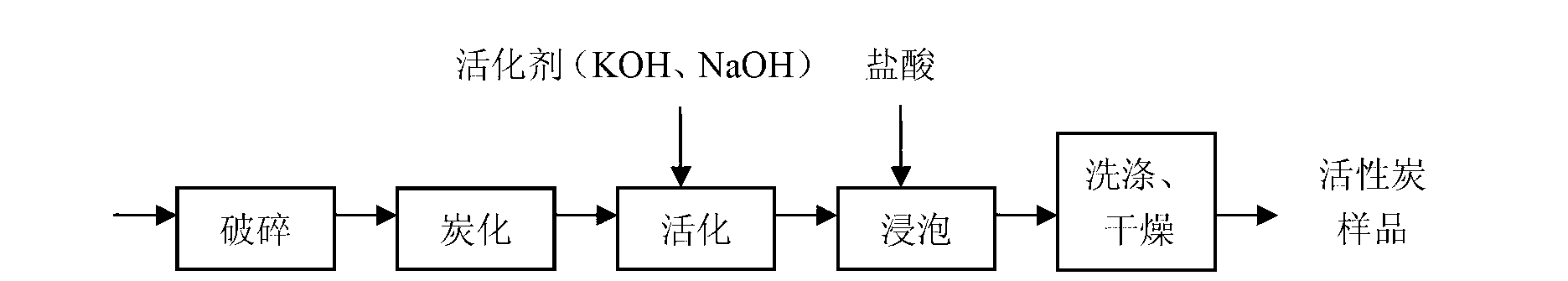

A technology of eggplant straw and activated carbon is applied in the field of preparation of eggplant straw activated carbon, which can solve the problems of environmental pollution, resource waste and the like, and achieve the effects of low corrosiveness, small environmental pollution and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A certain amount of discarded crop eggplant stalks were selected, washed, dried, and crushed to 1 cm. Carbonize for 30 minutes, carbonization temperature is 650°C, KOH:straw mass ratio is 2:1, activation time is 100min, activation temperature is 650°C, heat in a heating furnace, then cool to room temperature and take out. Then soak it in 0.1mol / L hydrochloric acid, stir continuously at about 60°C for 1 hour, wash it with hot distilled water until neutral, dry, and sieve to 200 mesh to obtain powdered eggplant straw activated carbon. The activated carbon prepared under this condition has an iodine adsorption value of 2038.5mg / g, and a methylene blue adsorption value of 41.3mL / 0.1g, which far exceeds the national first-class activated carbon standard for wood water purification (GBT138032-1999, activated carbon for wood water purification-- Grade product quality indicators: iodine adsorption value ≥ 1000mg / g, methylene blue value ≥ 9ml / 0.1g).

Embodiment 2

[0027] A certain amount of discarded crop eggplant stalks were selected, washed, dried, and crushed to 1 cm. After carbonization for 30 minutes, activate at an activation temperature of 700°C, an activation time of 80 minutes, and a carbonization temperature of 450°C, using activators (KOH and NaOH), with a mass ratio of KOH:NaOH:eggplant straw of 3:1:1. Heat in the oven, then cool to room temperature and remove. Then soak it in 0.1mol / L hydrochloric acid, stir continuously at 60°C for 1 hour, rinse with hot distilled water until neutral, dry, and sieve to 200 mesh to obtain powdered eggplant straw activated carbon. Activated carbon with an iodine adsorption value of 2356.40mg / g and a methylene blue adsorption value of 42mL / 0.1g can be obtained, which far exceeds the national standard for first-class activated carbon for wood water purification (GBT138032-1999, quality index for first-class activated carbon for wood water purification: iodine adsorption value ≥1000mg / g, methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Adsorption value of methylene blue | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com