Technique for preparing sulfuric acid from SO2 by non-equilibrium state high-concentration twice conversion

A kind of high-concentration, sulfuric acid production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

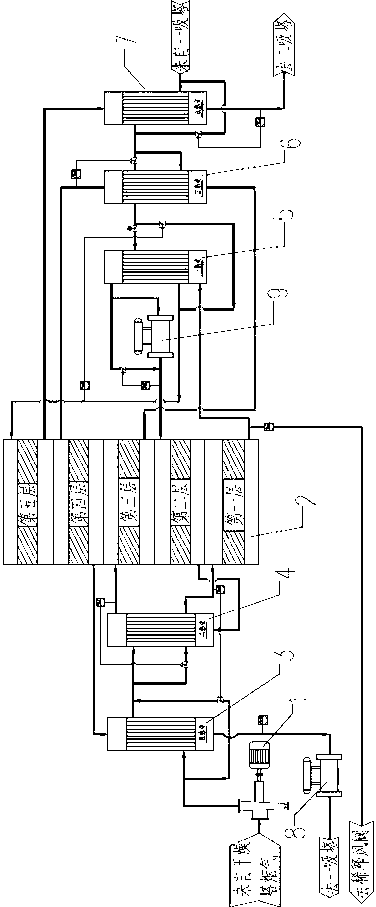

[0011] Attached below figure 1 The present invention is described in detail with embodiment;

[0012] from SO 2 Blower 1, SO 2 18% cold SO 2 The flue gas first enters the IV heat exchanger 3 and exchanges heat with the hot flue gas at the outlet of the fourth section of the converter 2. The flue gas undergoes heat exchange. After two heat exchanges, the flue gas temperature reaches the light-off temperature of the catalyst and enters the first stage of the converter for conversion reaction. Since the loading amount of the catalyst is less than normal, the conversion rate of the reaction is lower than the equilibrium conversion. At this time, the conversion rate is preferably less than 45%. (In general, the equilibrium conversion rate is about 65% as the concentration changes). flue gas SO 2 The concentration is about 12%, after which it is a conventional secondary conversion process. The flue gas at the outlet of the first section of the converter is cooled by the I hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com