Stick-slip rotating and positioning device

A positioning device, stick-slip technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of large positioning error, large volume, and the inapplicability of rotary positioning devices, and achieve easy operation, small size, and High applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

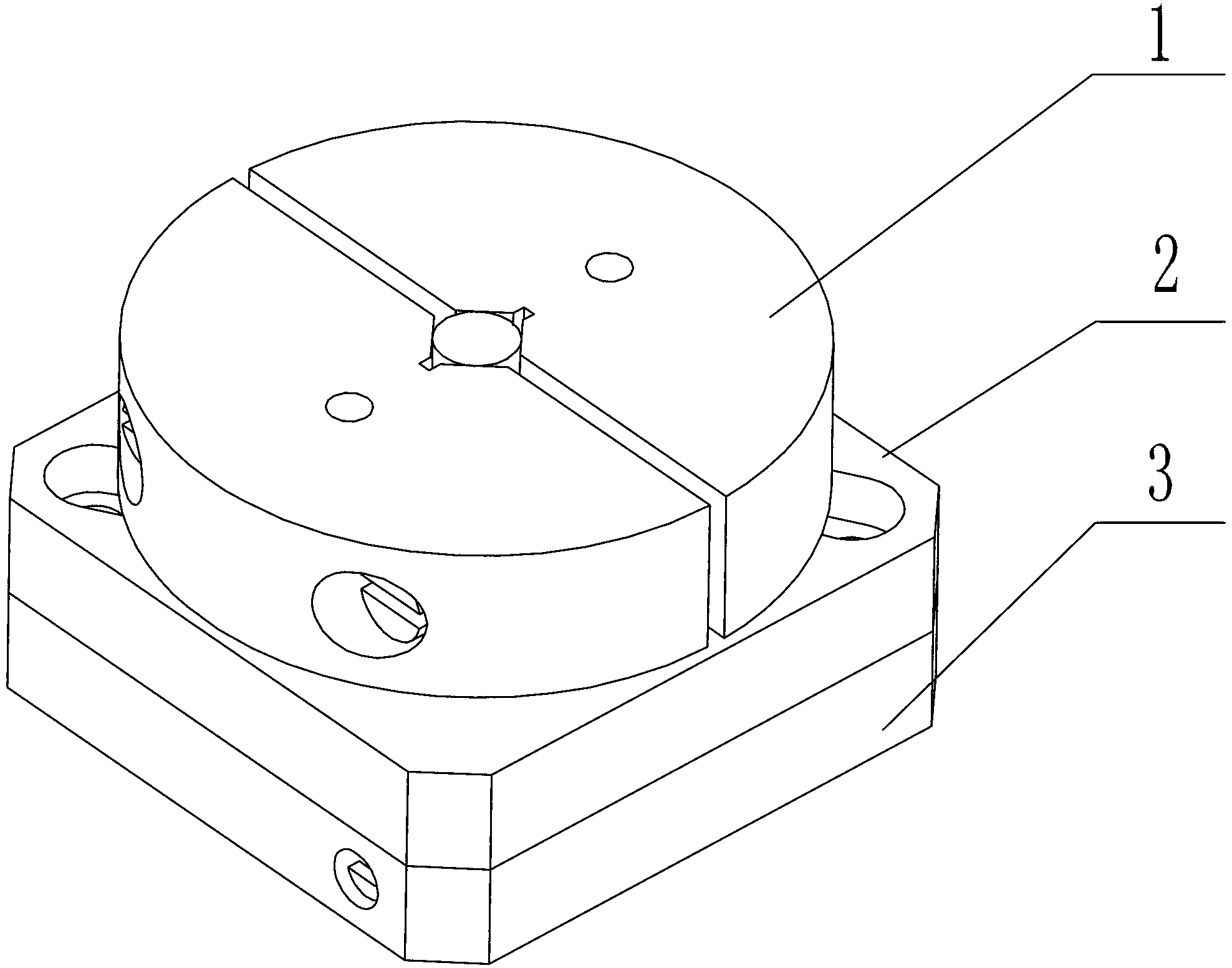

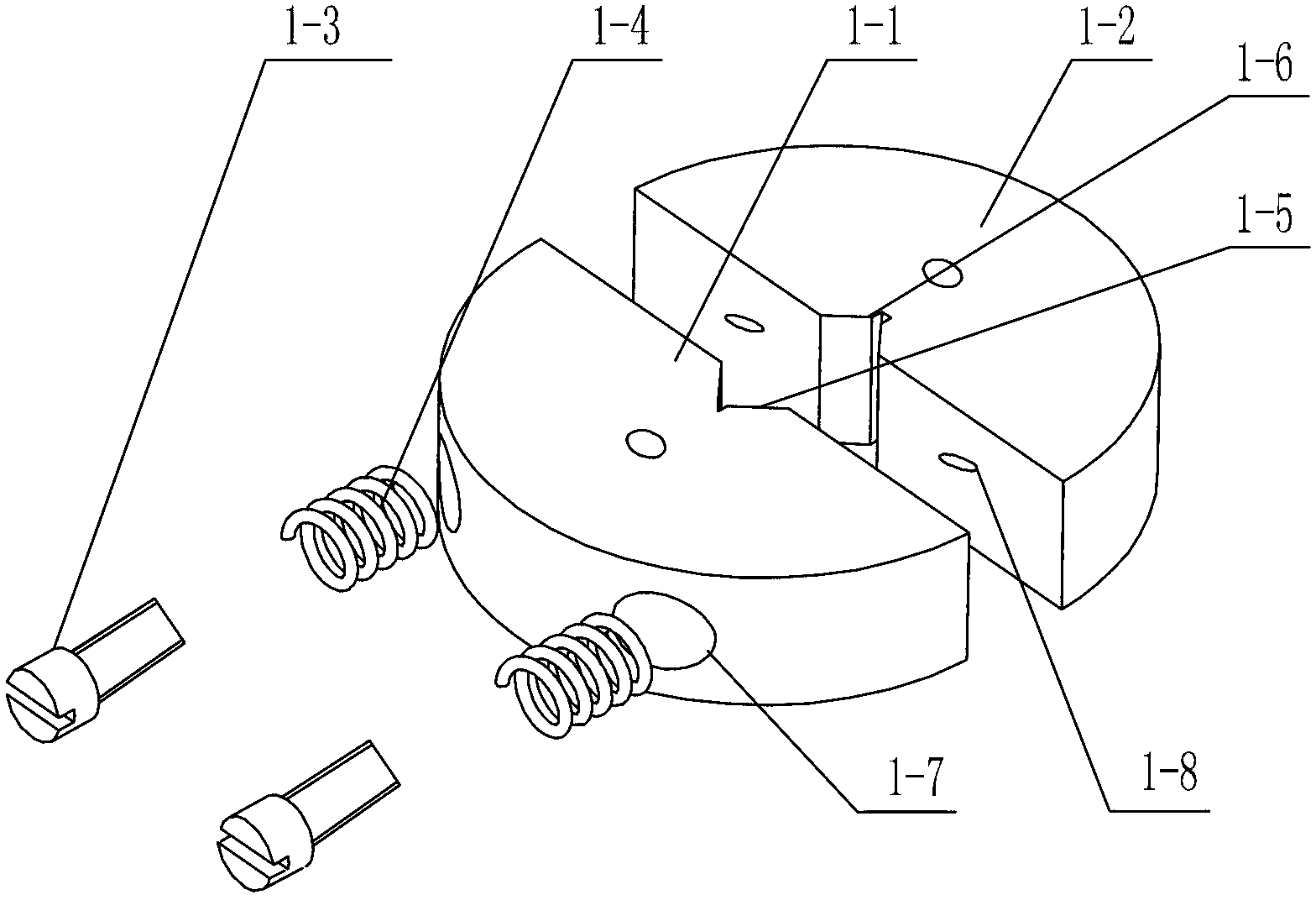

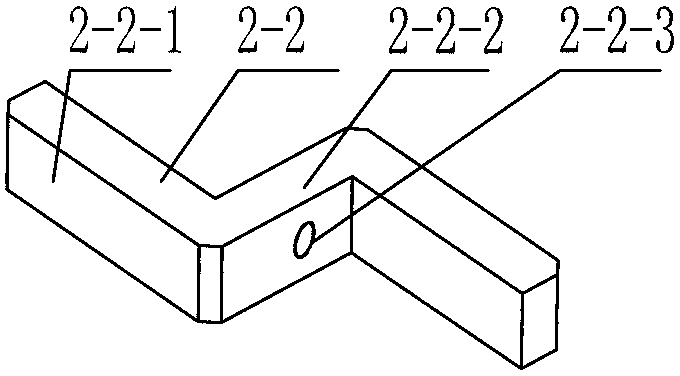

[0008] Specific implementation mode one: combine Figure 1-Figure 13 Describe this embodiment, a stick-slip rotary positioning device, the device includes a rotating unit 1, a drive unit 2 and a base 3; the rotating unit 1 includes a first rotating semicircular table 1-1 and a second rotating semicircular table 1-2 , the driving unit 2 includes a driving elastic table 2-1 and a driving rotating plate 2-2, the base 3 includes a base 3-1 and a piezoelectric ceramic driver 3-2, and the center of the section of the first rotating semicircular table 1-1 is processed with The first V-shaped groove 1-5, the second V-shaped groove 1-6 is processed at the center of the cross section of the second rotating semi-circular platform 1-2, the first rotating semi-circular platform 1-1 and the second rotating semi-circular platform 1-2 are opposite The installation combination is a round table, the first V-shaped groove 1-5 and the second V-shaped groove 1-6 are arranged oppositely, the drivin...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 , figure 2 and Figure 8 Describe this embodiment, a stick-slip type rotary positioning device, the first rotary semicircular table 1-1 is processed with two countersunk holes 1-7, the center line of the counterbore 1-7 is aligned with the first rotary semicircular table The straight face on one side of 1-1 is vertical, and two first threaded holes 1-8 are provided on the second rotating semicircular table 1-2, and the two first threaded holes 1-8 are opposite to the two countersunk holes 1-7 The settings are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 , figure 2 and Figure 8 Describe this embodiment, a stick-slip rotary positioning device, the device also includes two first adjusting bolts 1-3 and two adjusting springs 1-4, the adjusting springs 1-4 are sleeved on the first adjusting bolts 1- 3 on the screw rod, the adjustment spring 1-4 is installed in the first threaded hole 1-8 through the countersunk hole 1-7, and the two semicircular bodies can be effectively fixed by the adjustment spring 1-4 and the first adjustment bolt 1-3 screw rod, This method can precisely adjust the frictional force between the rotating unit 1 and the rotating shaft 2-1-2 to make the structure compact, and the other is the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com