Air control brake control method and system for dual-control membrane type drilling machine

A brake control, film-type technology, applied in the hoisting device and other directions, can solve problems such as no technical solutions, and achieve the effects of improved controllability, short lag time, and large braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

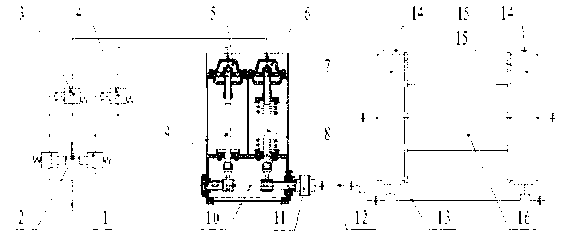

[0010] As shown in the figure, the structural principle of a dual-control film type air-controlled brake. Including manual double control valve 2, normally closed brake controller 3, normally open brake controller 4, normally open brake film cylinder 5, normally closed brake film cylinder 6, brake spring 7, normally closed cylinder piston rod 8, normally open cylinder Piston rod 9, brake output shaft 10, coupling 11, winch brake handle shaft 12, winch brake shaft 13, winch brake band 14, winch brake hub 15, winch drum 16 etc. are formed. Connect as shown in the figure. Its control method is as follows: compressed air is input from the air source input port 1, and after passing through the manual double-connected control valve 2, two complementary pressure-regulating control airs are output, and the pressure-regulating air is respectively passed through the respective brake controllers (3 and 4). The signal is amplified, and then the normally open brake membrane cylinder 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com