Automatic positioning paper-delivery shaft structure of journal printer

An automatic positioning and printer technology, applied in the direction of printing device, printing, etc., can solve the problem of inconvenient replacement of printing paper, and achieve the effect of simple structure and quick disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

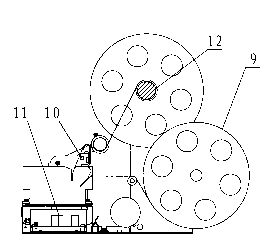

[0012] See attached figure 1 , when the log printer is working, the printing paper on the paper roll 9 is wound on the take-up shaft 12 through the intermediate roller, and the control module 11 controls the print head 10 to print the recorded information on the printing paper. When the printing paper is used up, , the printing paper needs to be taken off on the delivery shaft 12.

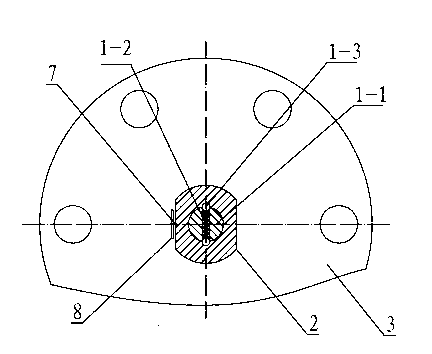

[0013] See attached figure 2 , 3 , 4, a journal printer disclosed in the present invention automatically locates the paper receiving shaft structure, comprising: a paper receiving shaft assembly, a left paper receiving baffle 3 installed on the paper receiving shaft assembly, a right paper receiving baffle 5 and a paper receiving shaft Gear 4, the delivery shaft assembly is composed of the left half shaft 2 and the right half shaft 1, one end of the left half shaft 2 is fixedly connected with the left baffle 3, and at the same time it is connected with the delivery shaft gear 4 Fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com