Fully-automatic trimming hanger for aerated concrete production line and trimming method

A kind of aerated concrete and production line technology, applied in the direction of manufacturing tools, ceramic molding machines, cranes, etc., can solve the problems of low degree of automation, low production efficiency, high production cost, etc., achieve high degree of automation, simple structure, easy operation and management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments.

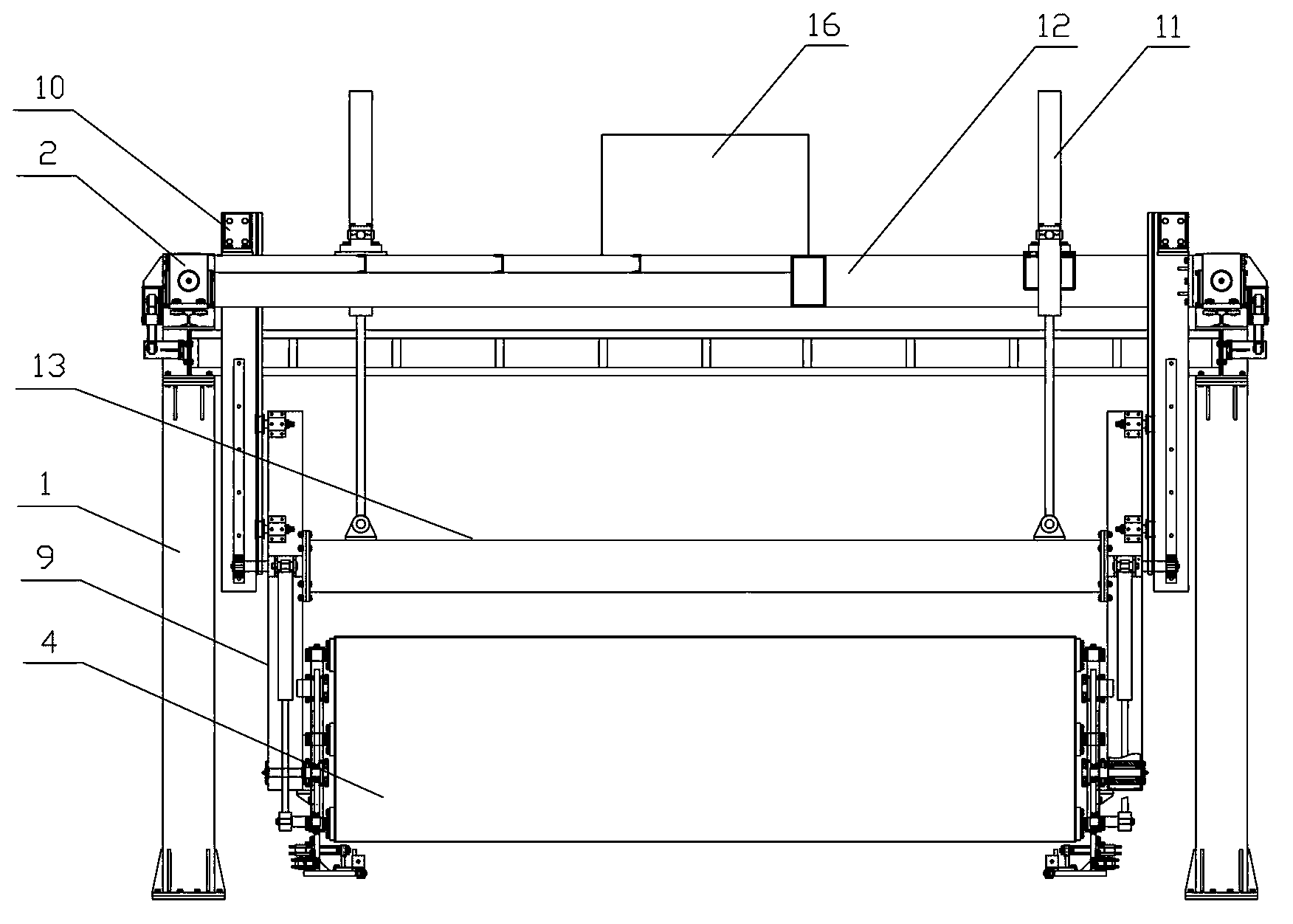

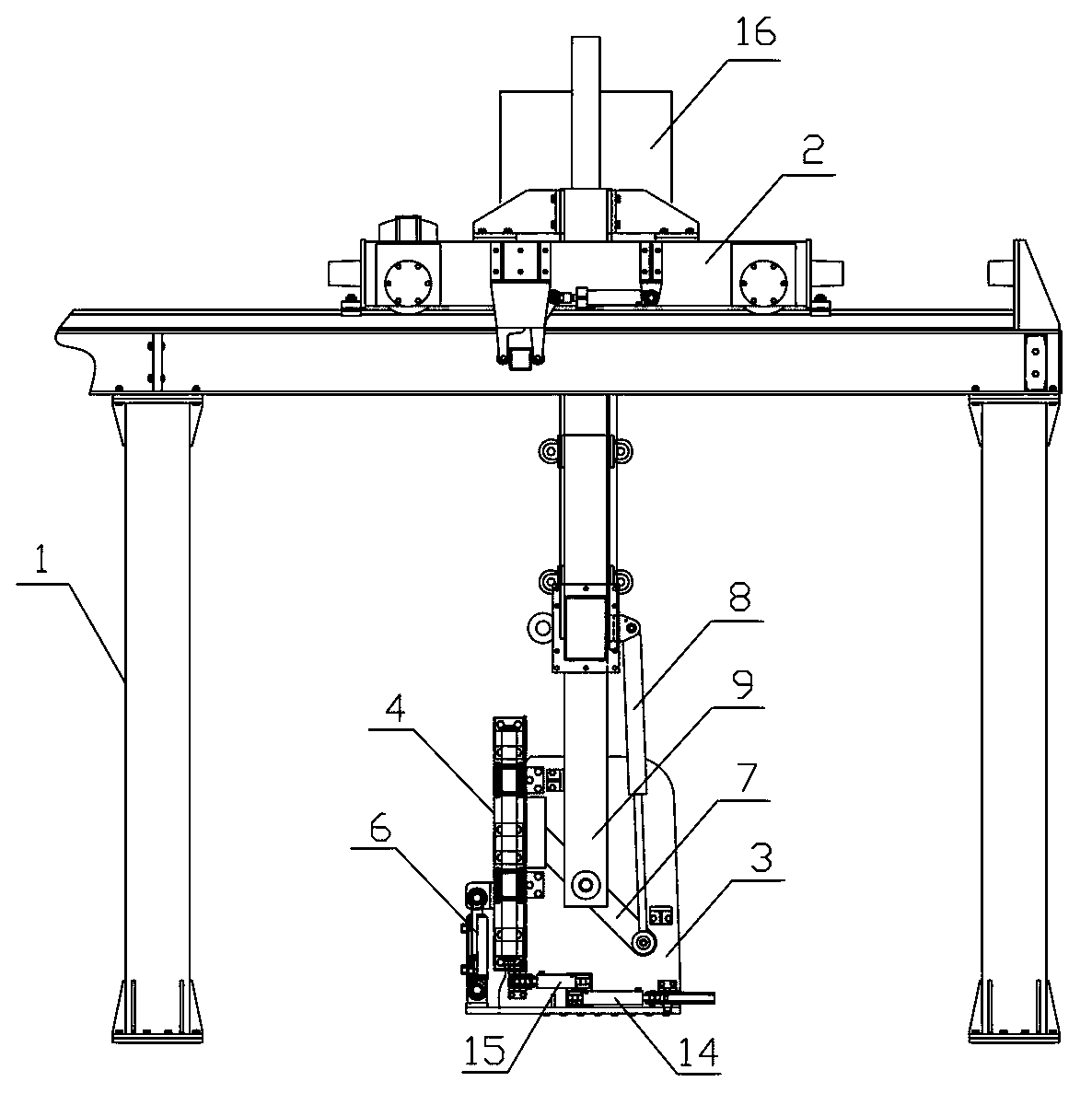

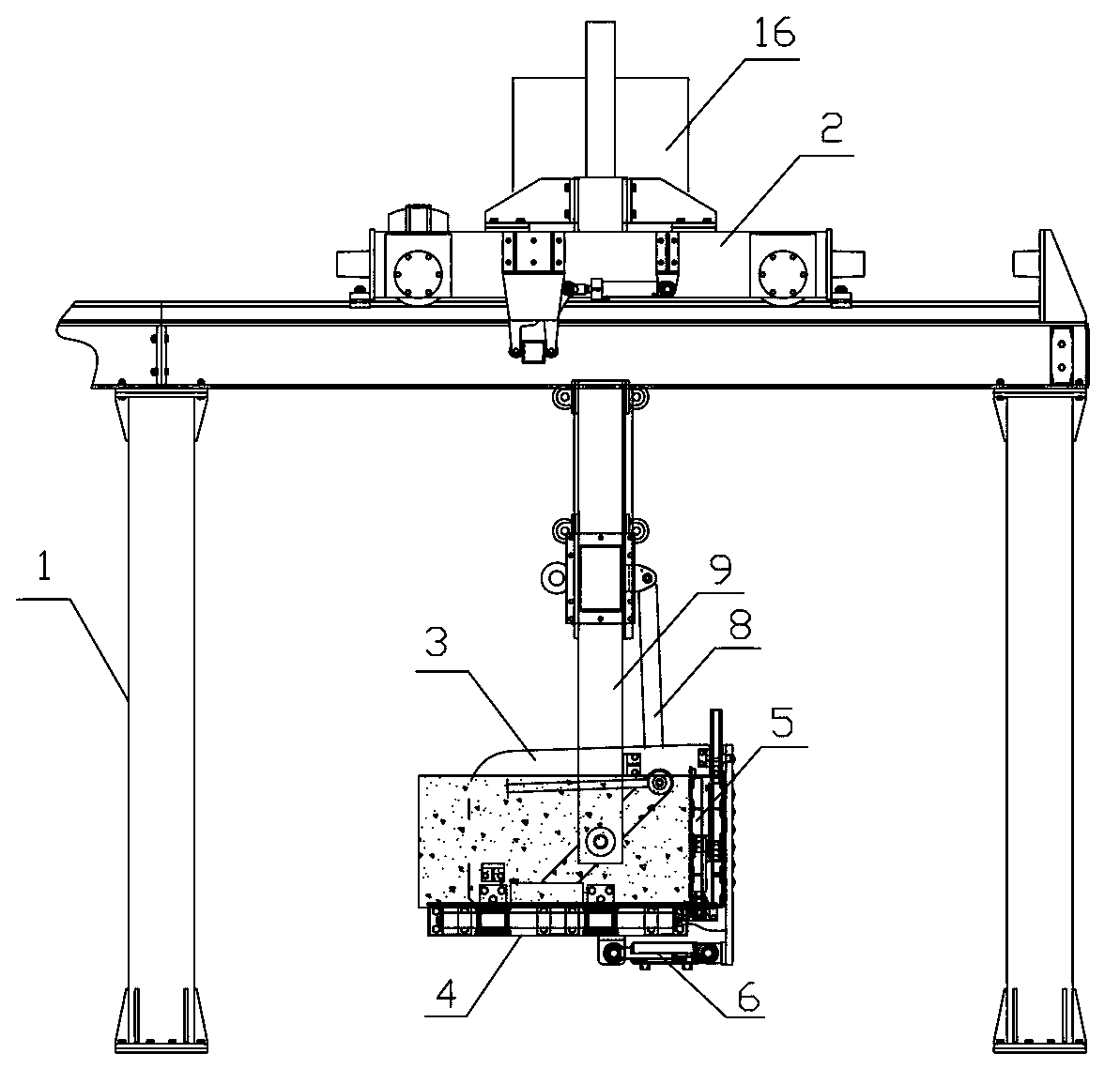

[0022] refer to figure 1 , figure 2 and image 3 , a fully automatic edge-removing spreader for an aerated concrete production line according to the present invention, comprising a fixed frame 1, a traveling trolley 2 movable on the fixed frame 1, and a positioning device arranged on the traveling trolley 2 And the lifting device, also includes an automatic edge removal device, the automatic edge removal device includes a turning device that is movably connected to the lifting device, two spreader fixing seats 3 that are hinged with the turning device on both sides, a slidable A longitudinally arranged bottom plate 4 connected between two spreader fixing seats 3, a horizontal side plate 5 supporting the body, and a clamping oil cylinder set on the spreader fixing seat 3 for pushing the side plate 5 to move together with the body And the separation oil cylinder 6 connected between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com